Chemical mechanical polishing liquid used for flattening barrier layer

A chemical mechanical and polishing fluid technology, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of low polishing rate, low yield, and copper corrosion of the barrier layer, and achieve reduced production costs, strong correction capabilities, and improved work efficiency effect

Inactive Publication Date: 2017-07-07

ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

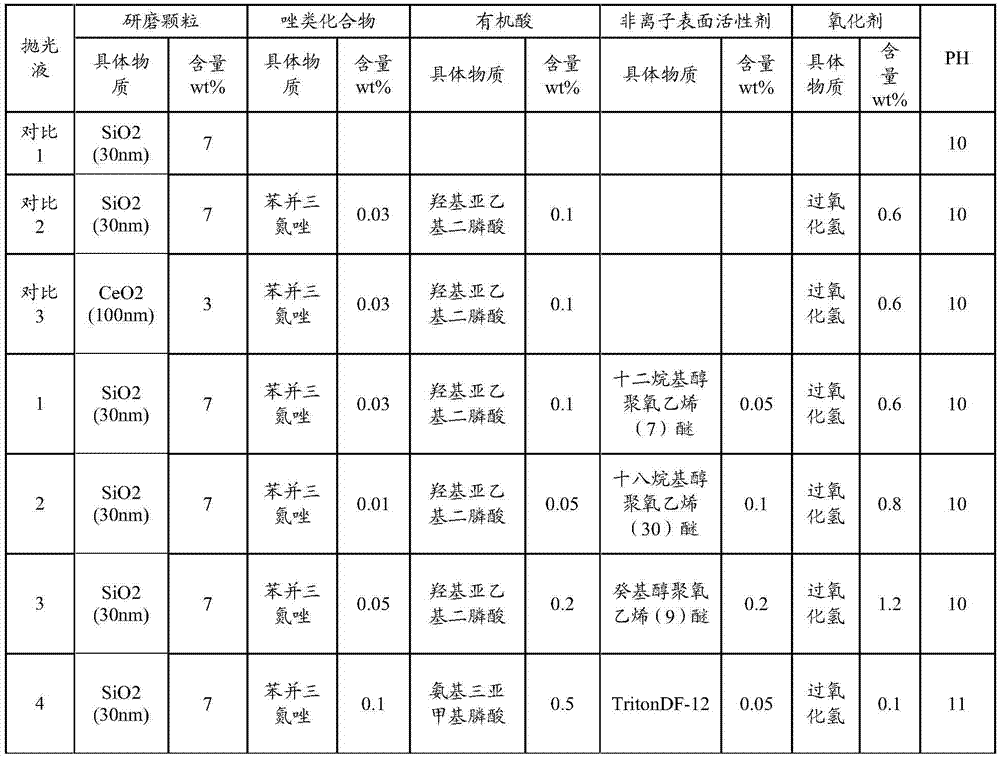

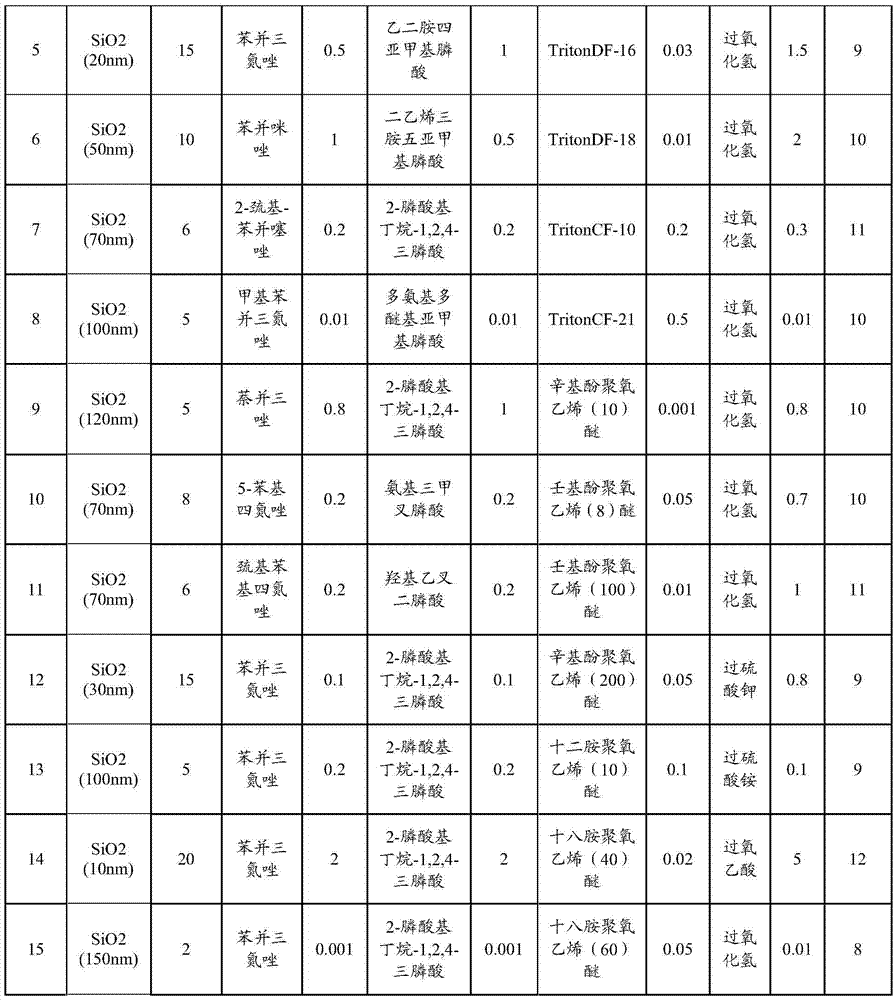

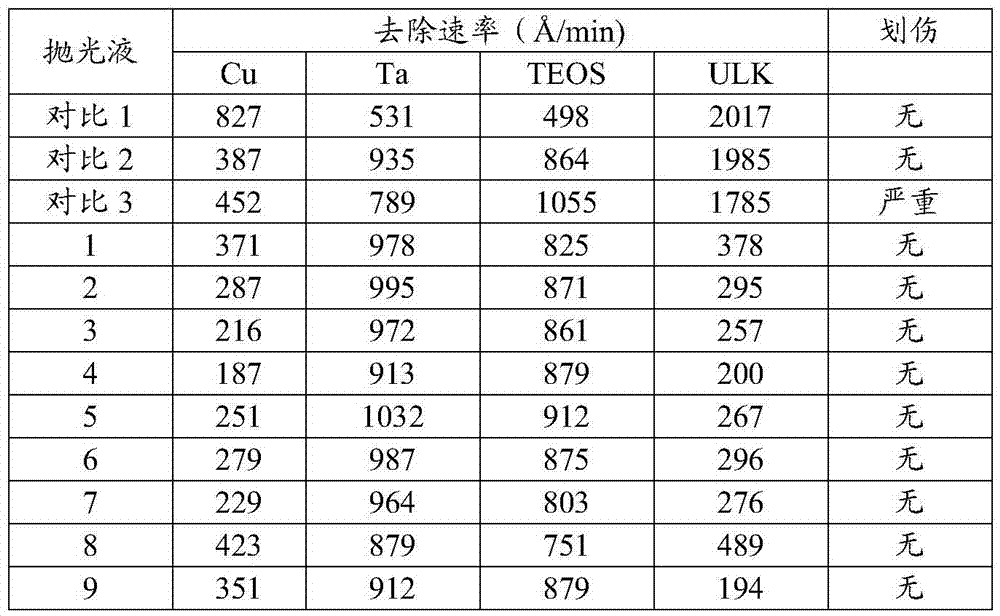

[0005] At present, reports on polishing fluids can be divided into alkaline and acidic types. For example, CN1400266 discloses an alkaline barrier layer polishing fluid, which includes silica abrasives, amine compounds and nonionic surfactants. Polishing liquid can corrode copper; CN101372089A discloses a kind of alkaline barrier layer polishing liquid, and this polishing liquid comprises silica abrasive material, corrosion inhibitor, oxidizing agent, noni

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses chemical mechanical polishing liquid used for flattening a barrier layer. The polishing liquid comprises grinding particles, an azole compound, organic phosphonic acid, nonionic surfactant and an oxidizing agent. The chemical mechanical polishing liquid has the advantages that the polishing rate and selection ratio requirements of various materials during barrier layer polishing can be satisfied while high correcting ability to semiconductor device surface defects is achieved, flattening can be achieved fast, work efficiency is increased, and product cost is lowered.

Description

technical field [0001] The invention relates to a chemical mechanical polishing liquid, in particular to a chemical mechanical polishing liquid used for barrier layer planarization and its application method Background technique [0002] In today's integrated circuit manufacturing field, the process standards of interconnection technology are constantly improving. The specific performance is that the number of layers in the interconnection process is gradually increasing, and at the same time, its feature size is continuously shrinking. Therefore, the requirements for the surface flatness of silicon wafers are also increasing. high. Because creating complex and dense structures on semiconductor wafers is very limited if planarization cannot be achieved, chemical mechanical polishing (CMP) is currently the most effective method for achieving planarization of the entire silicon wafer. [0003] The CMP process is a processing method that obtains surface planarization through c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09G1/02

CPCC09G1/02

Inventor 姚颖荆建芬蔡鑫元邱腾飞宋凯

Owner ANJI MICROELECTRONICS TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com