Mining spraying material for blocking air leakage and preparation device of mining spraying material

A technology for plugging air and mining, which is applied to clay preparation devices, unloading devices, and raw material supply devices for sales, etc., can solve the problems of lack of performance plugging air materials, high cost of foam resin, and lack of strength for three-phase foam. Achieve stable and fast adhesive performance, excellent foam compression performance, and excellent bubble performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

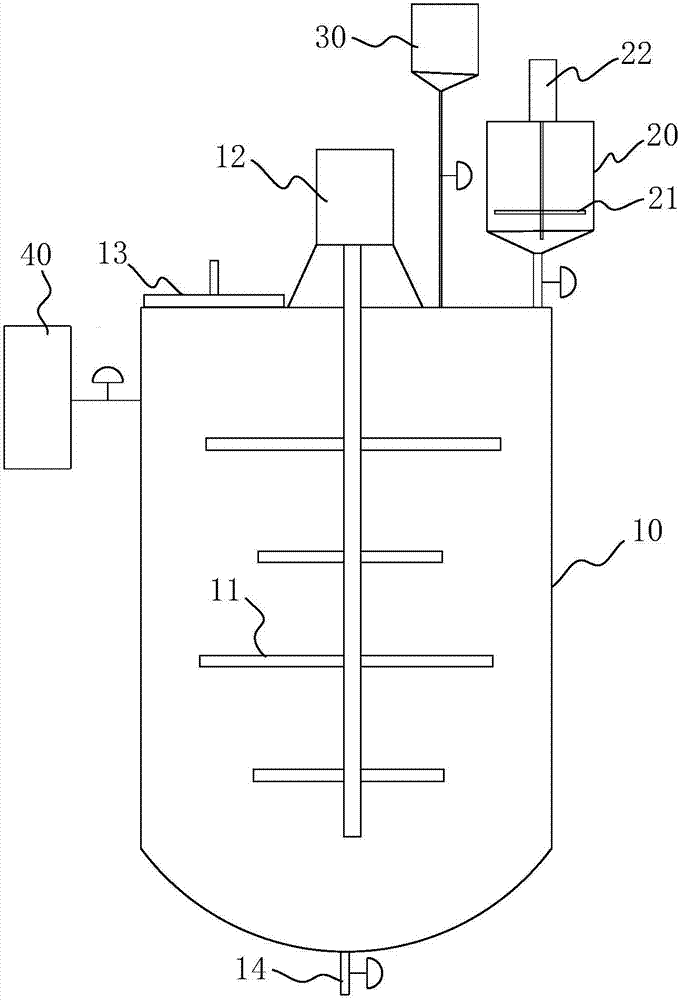

Method used

Image

Examples

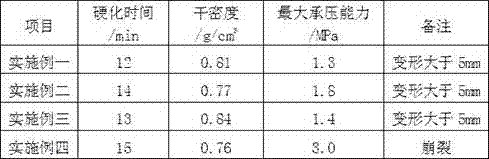

Embodiment 1

[0020] The materials are prepared according to the following weight composition: 100 parts of water, 25 parts of fly ash with a particle size range of 0.5 to 300 μm, 6 parts of gypsum, 20 parts of 42.5R cement, 12 parts of slaked lime, 0.5 parts of fatty alcohol polyoxyethylene ether, hydroxyl 0.8 parts of ethyl methyl cellulose, 2 parts of sodium lauryl sulfate, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 2.5 parts of polyphosphoric acid, 1.8 parts of hydroxypropyl starch ether with a viscosity of 600-800 mPas, acetic acid 1.2 parts of redispersible latex powder of ethylene-ethylene copolymer type.

[0021] The preparation steps are:

[0022] 1): Add 80 parts of water and all of the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methyl cellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator will evenly form a fly ash slurry. Rotation speed 1000 rpm;

[0023] 2): Add 15 parts of water and all the polyphosphoric acid, hydroxyp...

Embodiment 2

[0027] Prepare materials according to the following weight composition: 100 parts of water, 15 parts of fly ash with a particle size ranging from 0.5 to 300 μm, 6 parts of gypsum, 25 parts of 42.5R cement, 10 parts of slaked lime, 0.8 parts of fatty alcohol polyoxyethylene ether, hydroxyl 0.5 parts of ethyl methyl cellulose, 1.2 parts of sodium lauryl sulfate, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 2.5 parts of polyphosphoric acid, 1.6 parts of hydroxypropyl starch ether with a viscosity of 600-800 mPas, acetic acid 1 part of redispersible latex powder of ethylene-ethylene copolymer type.

[0028] The preparation steps are:

[0029] 1): Add 80 parts of water and all of the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methyl cellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator will evenly form a fly ash slurry. Rotation speed 1000 rpm;

[0030] 2): Add 15 parts of water and all the polyphosphoric acid, hydroxypropyl ...

Embodiment 3

[0034] The materials are prepared according to the following weight composition: 100 parts of water, 20 parts of fly ash with a particle size of 0.5 to 300 μm, 8 parts of gypsum, 25 parts of 42.5R cement, 10 parts of slaked lime, 0.8 parts of fatty alcohol polyoxyethylene ether, hydroxyl 0.7 parts of ethyl methyl cellulose, 1.5 parts of sodium lauryl sulfate, 1 part of fatty alcohol polyoxyethylene ether sodium sulfate, 2 parts of polyphosphoric acid, 1.6 parts of hydroxypropyl starch ether with a viscosity of 600 to 800 mPas, acetic acid 1.2 parts of redispersible latex powder of ethylene-ethylene copolymer type.

[0035] The preparation steps are:

[0036] 1): Add 82 parts of water and all the fly ash, fatty alcohol polyoxyethylene ether, hydroxyethyl methyl cellulose, gypsum, cement, slaked lime into the main mixing tank, and the agitator will evenly form a fly ash slurry. Rotation speed 1000 rpm;

[0037] 2): Add 12 parts of water and all the polyphosphoric acid, hydroxypropyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com