Switch rocker arm single-way joint

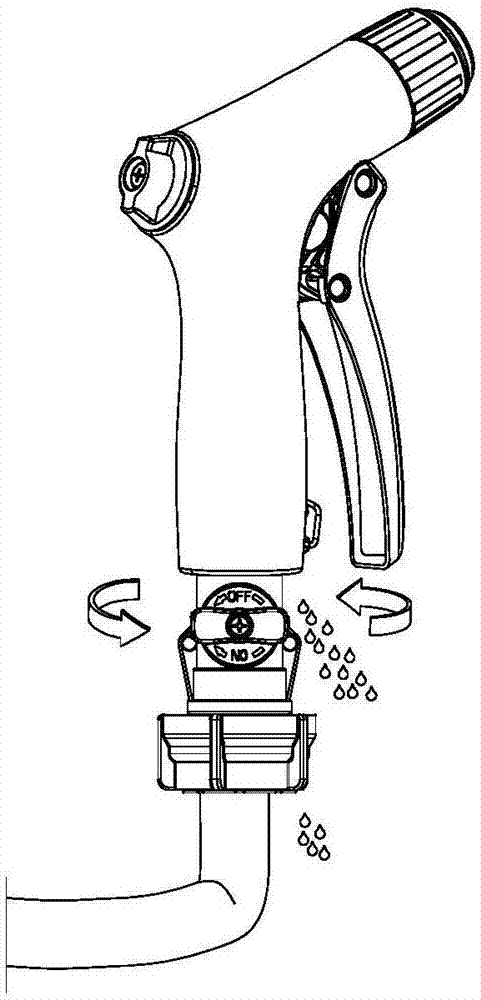

A switch and one-way technology, applied in the direction of passing components, injection devices, non-detachable pipe connections, etc., can solve the problems of loosening, inflexibility, and no water in the product links, so as to prevent product leakage and less water output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

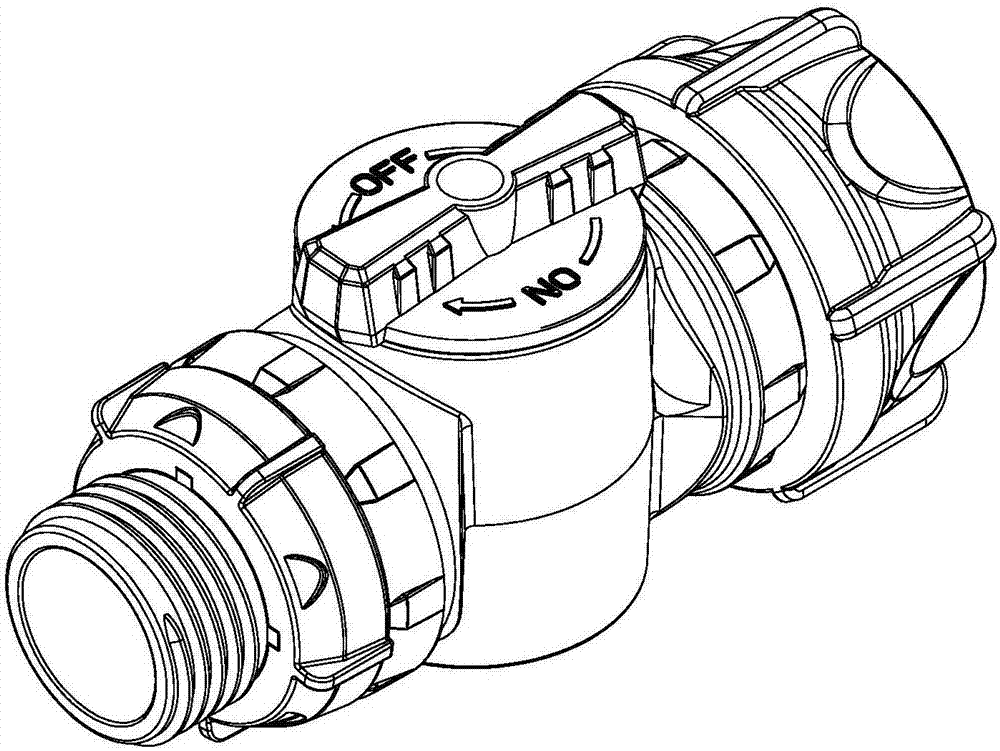

[0025] Such as Figure 3-6 As shown, this specific embodiment adopts the following technical scheme: it includes the switch male tooth 1, the male tooth sheath 2, the oil seal 3, the joint inner plug 4, the switch convex cover 5, the gasket 6, the rocker switch shaft core 7. Oil seal two 8. Switch limiter 9. Rocker switch 10. Phillips screw one 11. Joint inner plug two 12. Female tooth sheath 13. Oil seal three 14. Female tooth connector 15. Six-point univers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com