Electrostatic air purifier

An air purifier, electrostatic technology, applied in the direction of electrostatic separation, electrode structure, power supply technology, etc., can solve the problems of small impedance, cannot be replaced, large current, etc., to achieve the effect of large impedance and less leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the electrostatic air cleaner provided by the present invention will be described in detail below with reference to the drawings and specific embodiments. In these drawings, the same reference numerals are assigned to the same or corresponding components. The following are only the best implementation modes of the electrostatic air cleaner of the present invention, and the present invention is not limited to the following structures.

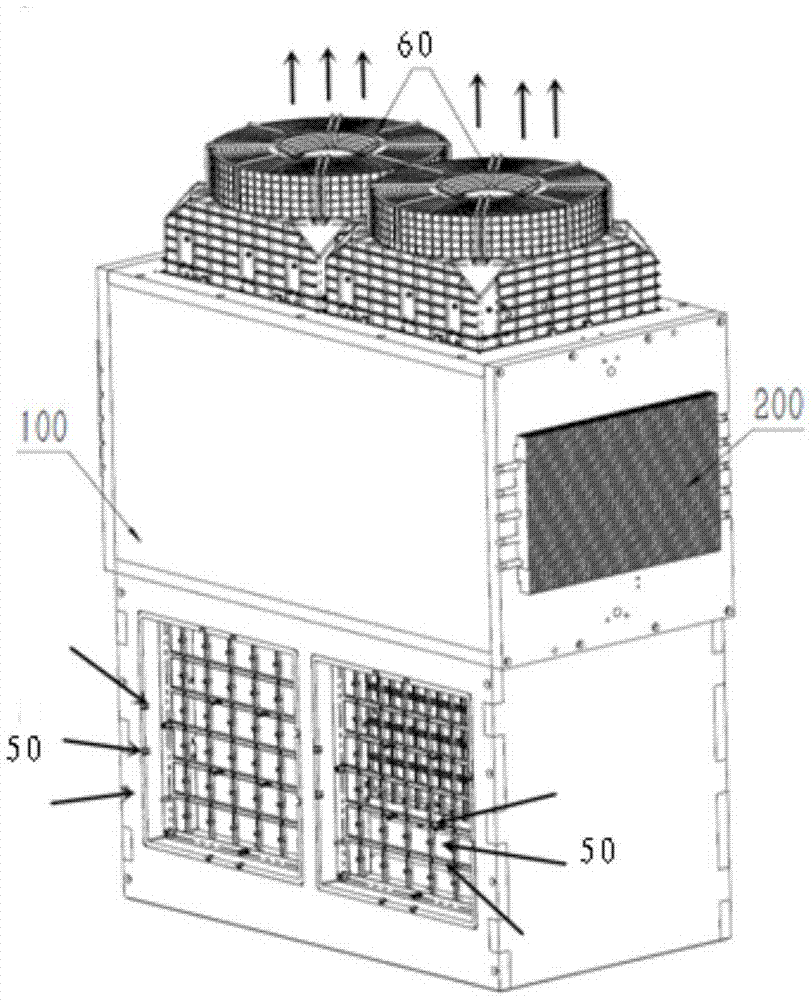

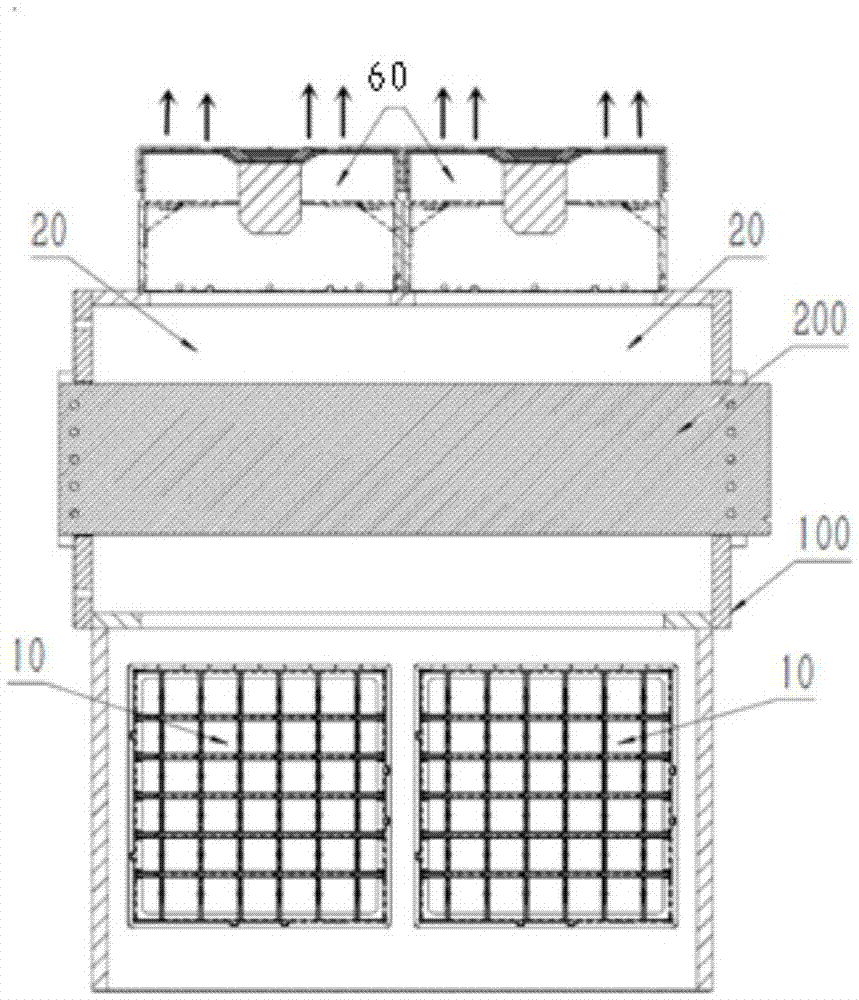

[0025] figure 1 It is a schematic diagram of the three-dimensional structure of the electrostatic air cleaner according to the embodiment of the present invention. figure 2 It is a cross-sectional view of the electrostatic air cleaner according to the embodiment of the present invention. Combine below figure 1 and figure 2 The electrostatic air cleaner of the present invention will be described.

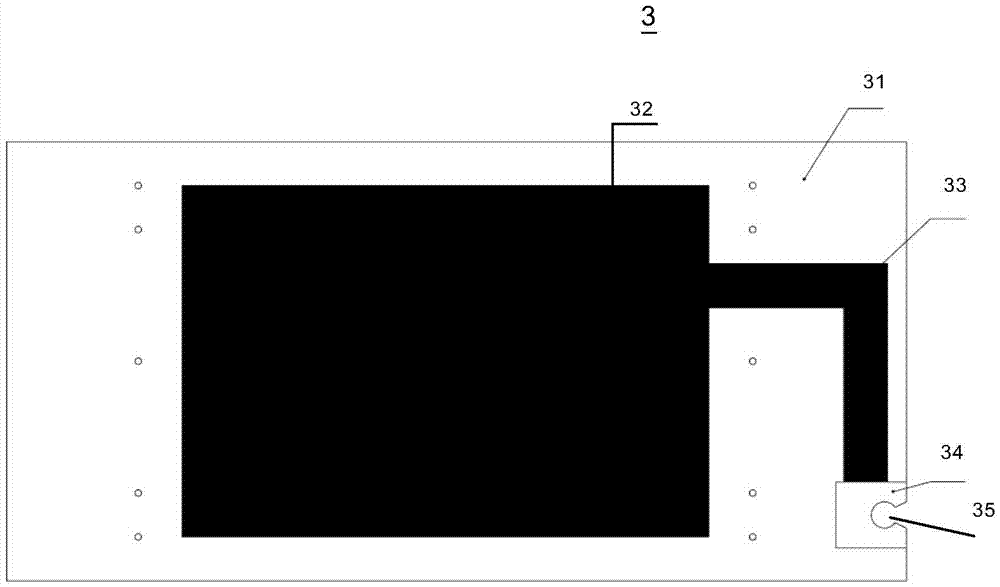

[0026] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com