Determination method of deepwater gas well blowout flow rate

A technology to determine the method and flow rate, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problems that the underwater wellhead cannot be shut down, the blowout flow rate cannot be obtained, and the blowout flow rate cannot be determined.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

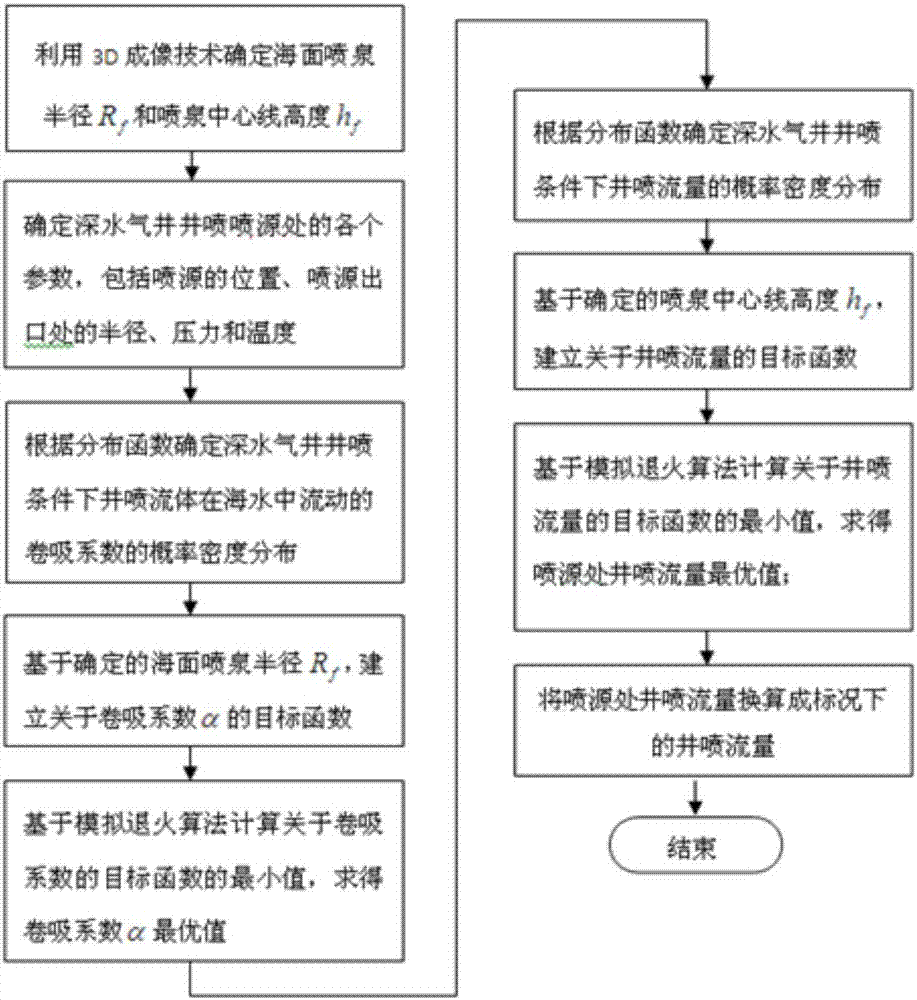

[0096] Such as figure 1 As shown, the present invention provides a method for determining the blowout flow rate of a deep-water gas well, comprising the steps of:

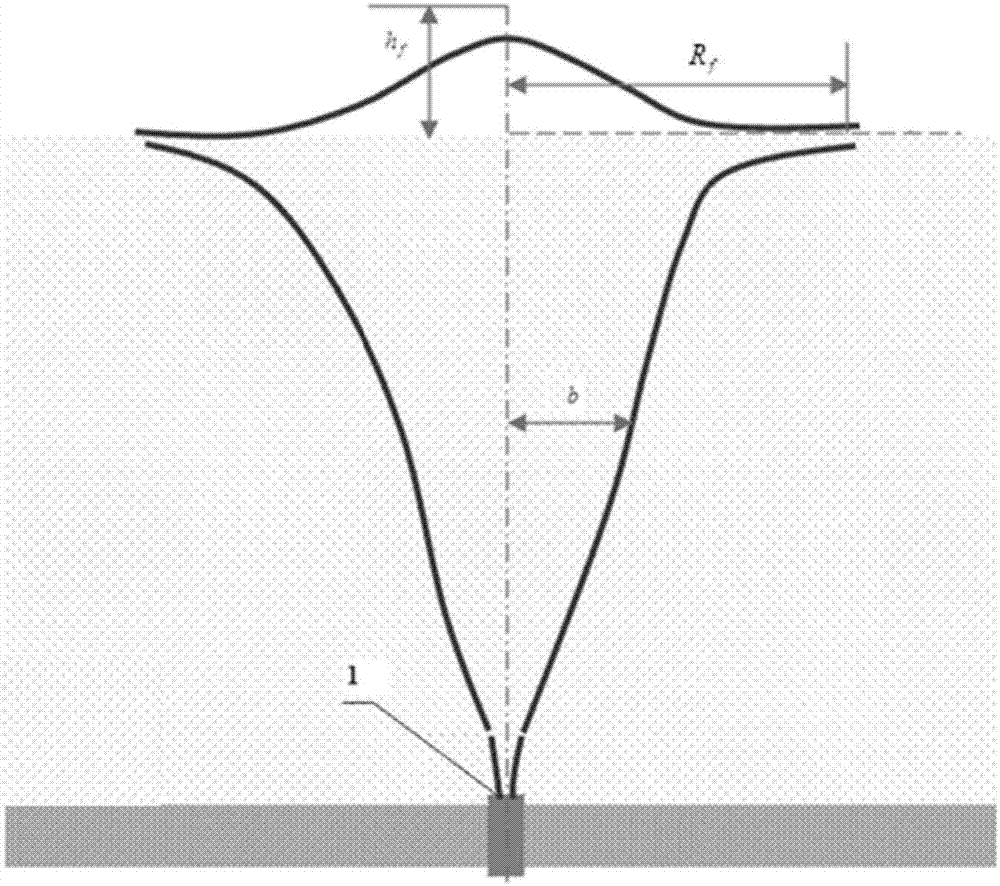

[0097] 1) Use 3D imaging technology to determine the radius R of the sea fountain f and fountain centerline height h f (Such as figure 2 shown).

[0098] 2) Determine various parameters at the blowout source 1 of the deep-water gas well, including the position of the blowout source 1, the radius, pressure and temperature at the outlet of the blowout source 1.

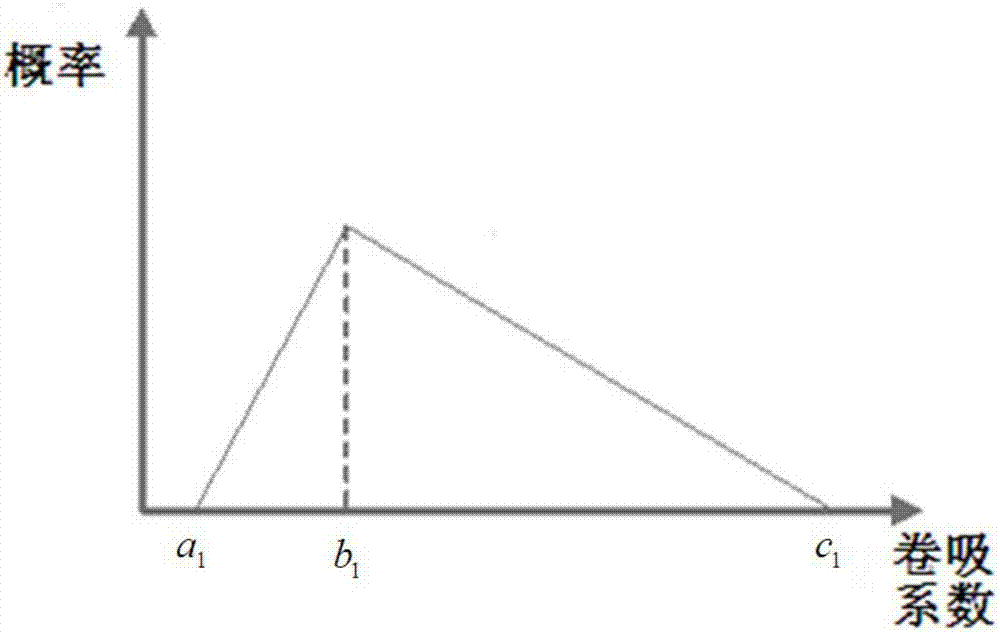

[0099] 3) Determine the probability density distribution of the entrainment coefficient of the blowout fluid flowing in the seawater under the blowout condition of the deep-water gas well, and the probability density distribution is a triangular distribution (such as image 3 shown), the distribution function is:

[0100] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com