Safety protection system of logging-while-drilling apparatus

A logging-while-drilling tool and safety protection technology, applied in the field of drilling equipment, can solve problems such as affecting work efficiency, low degree of automation, damage to parameter subsections, etc., and achieve the effect of meeting heat dissipation requirements, scientific and reasonable design, and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

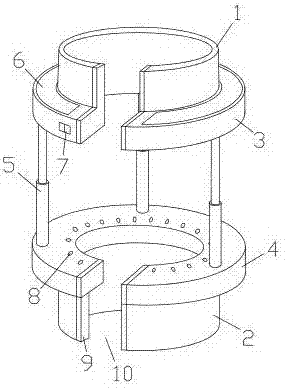

[0013] Such as figure 1 As shown, a logging-while-drilling tool safety protection system includes an upper chuck 1, a lower chuck 2, an upper stopper 3, a lower stopper 4, a telescopic arm 5, a power supply 6, a switch 7, a ball 8 and an anti-collision Pad 9; the upper chuck 1 is fixed at the upper mouth of the upper baffle, the lower chuck 2 is fixed at the lower mouth of the lower baffle 4, and the telescopic arm 5 is fixed between the upper baffle 3 and the lower baffle 4; One side of the upper baffle plate 3, the lower baffle plate 4, the upper chuck 1 and the lower chuck 2 is provided with co-located longitudinal cuts 10, and the inner walls of the two cuts 10 are adhered with anti-collision plates for protecting the short joints of parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com