Stepped electric-to-bag deduster structure

A dust collector, step-type technology, applied in the direction of chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of long renovation period, small electrostatic precipitator site, difficult redesign and installation of bag filter, etc. , to achieve the effect of reducing air velocity, slowing air turbulence, and increasing circulation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

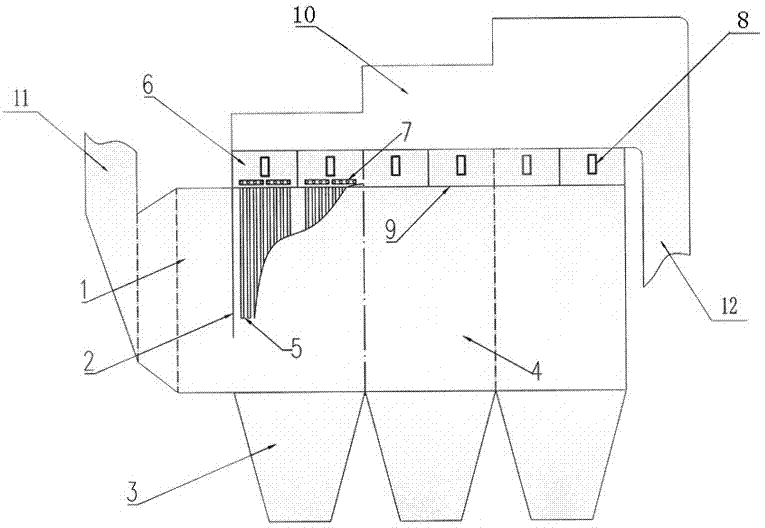

[0010] As attached figure 1 As shown, a stepped electric bag filter structure includes an air inlet pipe 11, a box body 4, an ash hopper 3, and an air outlet pipe 12. A filter bag 5 is provided in the box body 4, and the box body 4 An upper box body 6 and a clean air chamber 10 are sequentially arranged above the upper box body 6 including a blow pipe 7, an overhaul door 8 and a flower plate 9. The filter bag 5 is hung on the flower plate 9; The chamber 10 is arranged in a stepped shape, and the width of each step of the clean air chamber 10 is equal to the maximum width of the ash hopper 4. The air inlet pipe 11 is provided with a settling chamber 1, and an air flow partition 2 is provided between the settling chamber 1 and the middle box body 4, the top surface of the air flow partition 2, the top surface of the settling chamber 1, and the flower plate 9 At the same height, the lower bottom of the airflow partition 2 is slightly lower than the lower bottom of the filter bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com