Complex formulation stabilizing agent and application thereof

A technology of compounding stabilizers and parts by weight, which is applied in the direction of application, protein-containing food ingredients, and food ingredients as taste improvers, etc. It can solve the problems of rough taste and poor creamy feeling, and achieve fine and delicate taste and long-term shape retention , the effect of reducing fat content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

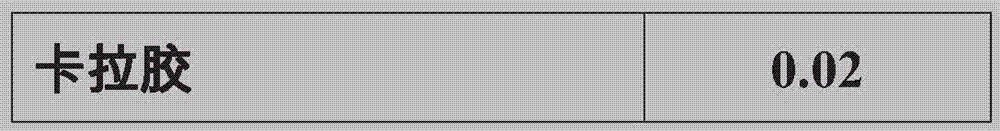

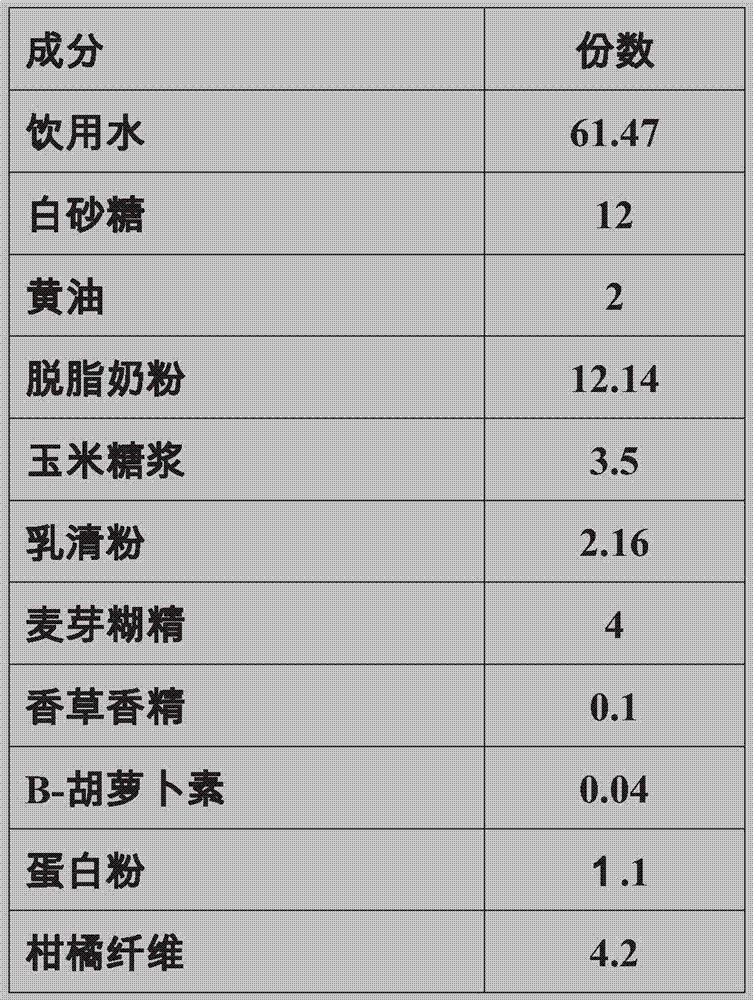

[0019] Make ice cream with the ingredients and parts by weight in the following table:

[0020]

[0021]

[0022] Apply the production technology of ice cream of the present invention to be:

[0023] Weigh each component according to the number of parts in the above table→60~65℃mixing→250-300bar / 38bar ultra-high pressure homogenization→83℃30 seconds sterilization→cooling→aging for 4 hours→freezing machine molding→packaging→quick freezing→packing box → storage.

[0024] For the ice cream produced in the present embodiment, the compound stabilizer of the present invention accounts for 5.6% of the ice cream content. The fat content of ice cream is only 2.5%, but it has the creamy taste of ice cream with a fat content of about 12%. At the same time, ice cream can be kept at 30°C for 20 minutes, and the expansion rate reaches 100%. It will not shrink for a year after being frozen.

Embodiment 2

[0026] Make ice cream with the ingredients and parts by weight in the following table:

[0027]

[0028]

[0029] Apply the production technology of ice cream of the present invention to be:

[0030] Weigh each component according to the number of parts in the above table→60~65℃mixing→250-300bar / 38bar ultra-high pressure homogenization→83℃30 seconds sterilization→cooling→aging for 4 hours→freezing machine molding→packaging→quick freezing→packing box → storage.

Embodiment 3

[0032] Make ice cream with the ingredients and parts by weight in the following table:

[0033]

[0034]

[0035] Apply the production technology of ice cream of the present invention to be:

[0036] Weigh each component according to the number of parts in the above table→60~65℃mixing→250-300bar / 38bar ultra-high pressure homogenization→83℃30 seconds sterilization→cooling→aging for 4 hours→freezing machine molding→packaging→quick freezing→packing box → storage.

[0037] The ice cream produced by the compound stabilizer of the present invention and the ultra-high pressure homogenization process has a fat content of only 2% to 3%, but has the creamy mouthfeel of ice cream with a fat content of about 12%; at the same time, the ice cream can be heated at 30°C If the expansion rate reaches 100% after being kept for 20 minutes, it will not shrink for a year after being frozen.

[0038] The invention caters to the health needs of the present era, enables the ice cream to achie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com