Energy storage and electrolyte mixing system for flow battery, and control method thereof

A technology of liquid flow battery and energy storage system, which is applied in the direction of fuel cells, fuel cell additives, circuits, etc., and can solve problems such as threats to the safe operation of the system, capacity decline of the liquid flow battery energy storage system, and liquid level difference. The effect of system capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

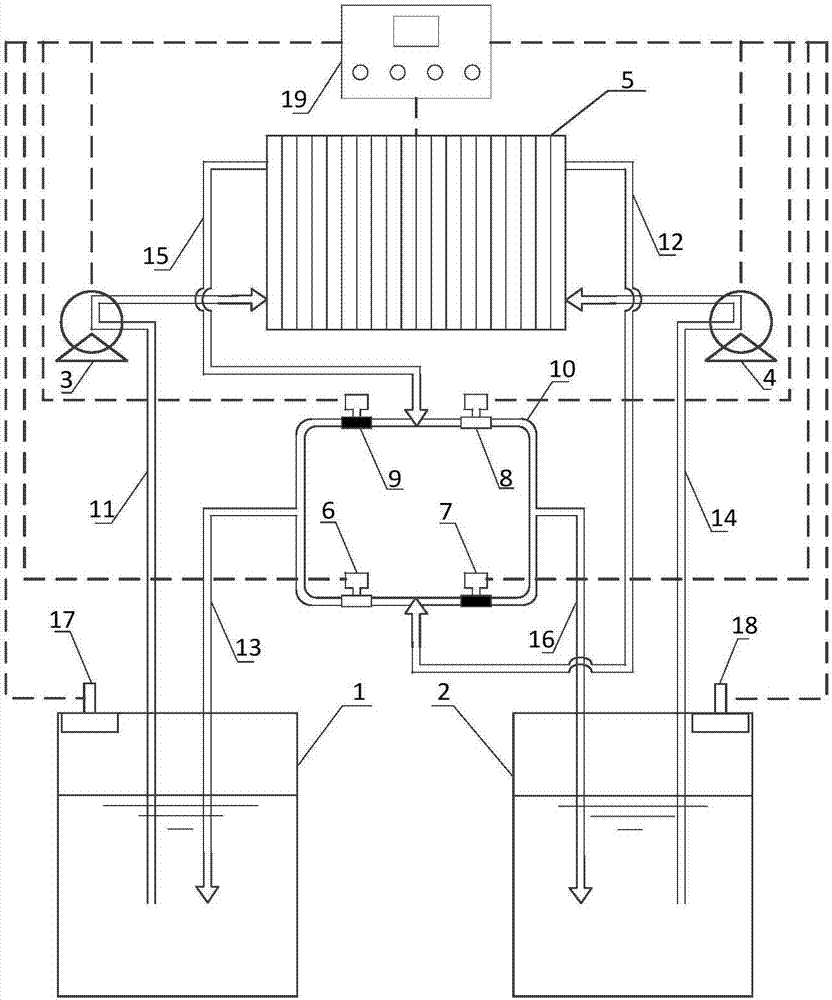

[0044] Such as figure 1 As shown, the flow battery energy storage mixed liquid system includes: positive electrolyte liquid storage tank 1, negative electrode electrolyte liquid storage tank 2, positive electrode electrolyte magnetic drive circulation pump 3, negative electrode electrolyte magnetic force drive circulation pump 4, stack 5, Battery management system BMS19, positive electrode stacking pipeline 11, positive electrode stacking pipeline 12, positive electrode tanking pipeline 13, negative electrode stacking pipeline 14, negative electrode stacking pipeline 15, negative electrode tanking pipeline 16, positive electrode liquid level Sensor 17, negative electrode liquid level sensor 18, mixed liquid pipeline;

[0045] The above mixed liquid pipeline includes: a loop 10, a positive electrode normal solenoid valve 6, a positive electrode mixed liquid solenoid valve 7, a negative electrode normal electromagnetic valve 8, and a negative electrode mixed liquid solenoid valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com