Laminated composite reflecting film and manufacturing method thereof

A reflective film and layered structure technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of poor luminance performance and poor stiffness of optical reflective films, achieve good luminance performance, reduce production costs, and improve reflection effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

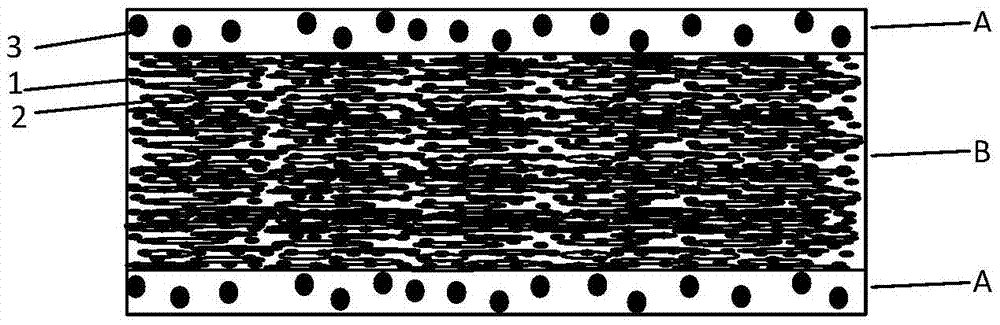

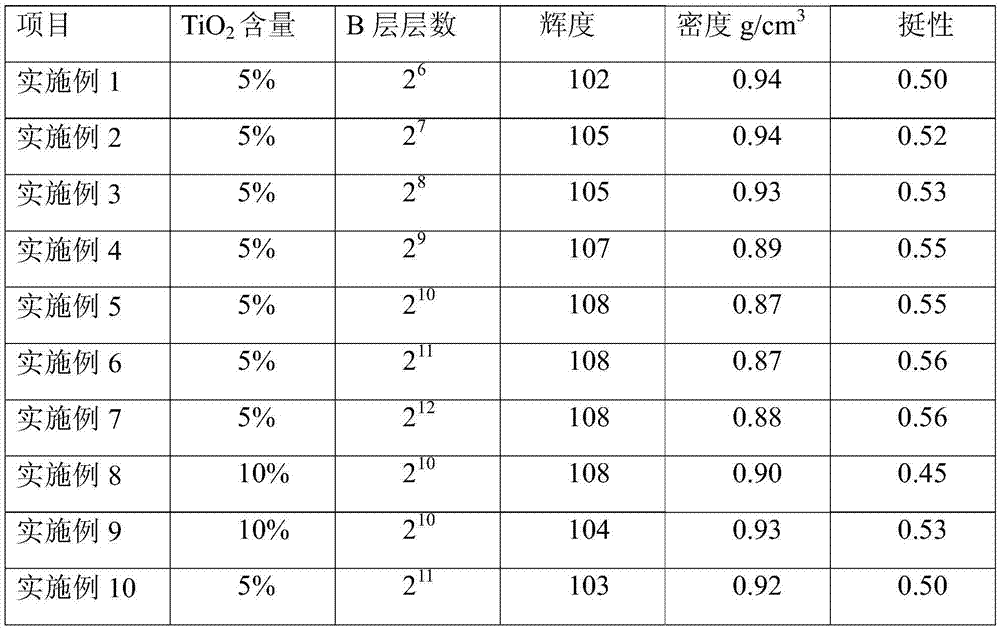

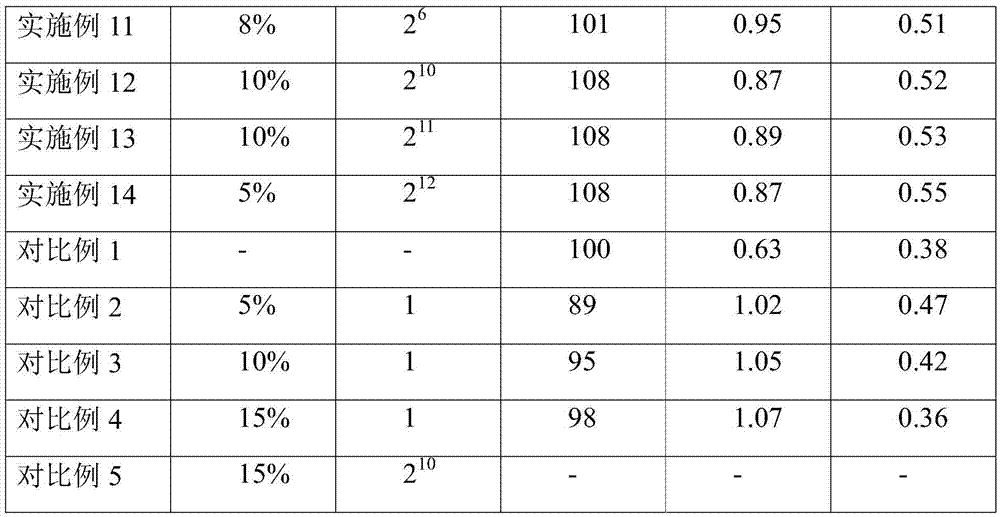

[0050] The invention provides a layered laminated reflective film, including ABA three-layer structure, A layer includes 97.7% of PET matrix resin, 2% of inorganic particle silicon dioxide, and 0.3% of quaternary ammonium salt type cationic antistatic agent, silicon dioxide The particle size is 3 μm. Layer B includes 80% of PET matrix resin, 15% of incompatible resin polymethylpentene, and 5% of white inorganic filler titanium dioxide, and the particle size of titanium dioxide is 0.3 μm. The melt of the B-layer formula passes through 6 splitter units, and merges with the A-layer formula melt in the adapter to enter the die casting sheet, and then stretches longitudinally and transversely to produce a reflective film. The thickness of the reflective film is controlled at 188μm , the B layer accounts for 90% of the total thickness, and the two A layers account for 10%. The B layer has 2 6 a layered structure.

Embodiment 2

[0052] For the layered laminated reflective film provided in Example 1, wherein, the melt of the B-layer formula passes through 7 splitter units, and merges with the A-layer formula melt in the adapter to enter the die casting sheet, and then passes through the longitudinal and transverse directions. The reflective film was stretched to obtain a thickness of 188 μm, the B layer accounted for 90% of the total thickness, and the two A layers accounted for 10% in total. The B layer has 2 7 a layered structure.

Embodiment 3

[0054] For the layered laminated reflective film provided in Example 1, wherein, the melt of the B-layer formula passes through 8 splitter units, and merges with the A-layer formula melt in the adapter to enter the die casting sheet, and then passes through the longitudinal and transverse directions. The reflective film was stretched to obtain a thickness of 188 μm, the B layer accounted for 90% of the total thickness, and the two A layers accounted for 10% in total. The B layer has 2 8 a layered structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com