High-efficiency drainage of coal roadway strip gas and regional outburst elimination method by segmental fracturing with long boreholes along the floor

A technology of layered drilling and long drilling, which is used in gas discharge, earthwork drilling, wellbore/well components, etc., can solve the problem of tight coal mining continuity, poor fracturing and drainage effects, and many outburst prevention measures. and other problems, to achieve the effect of rapid regional burst elimination, good pressure relief and anti-reflection effect, and short extraction time to meet the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

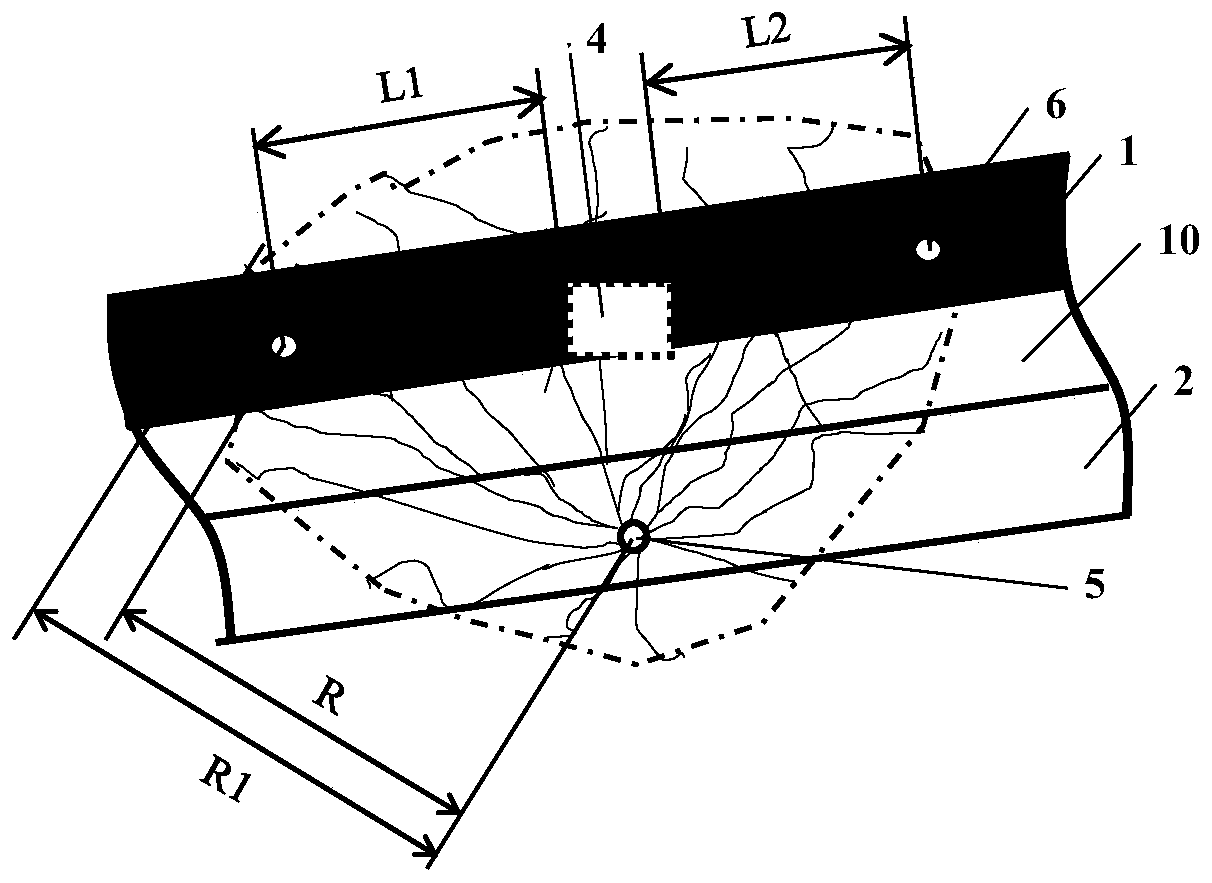

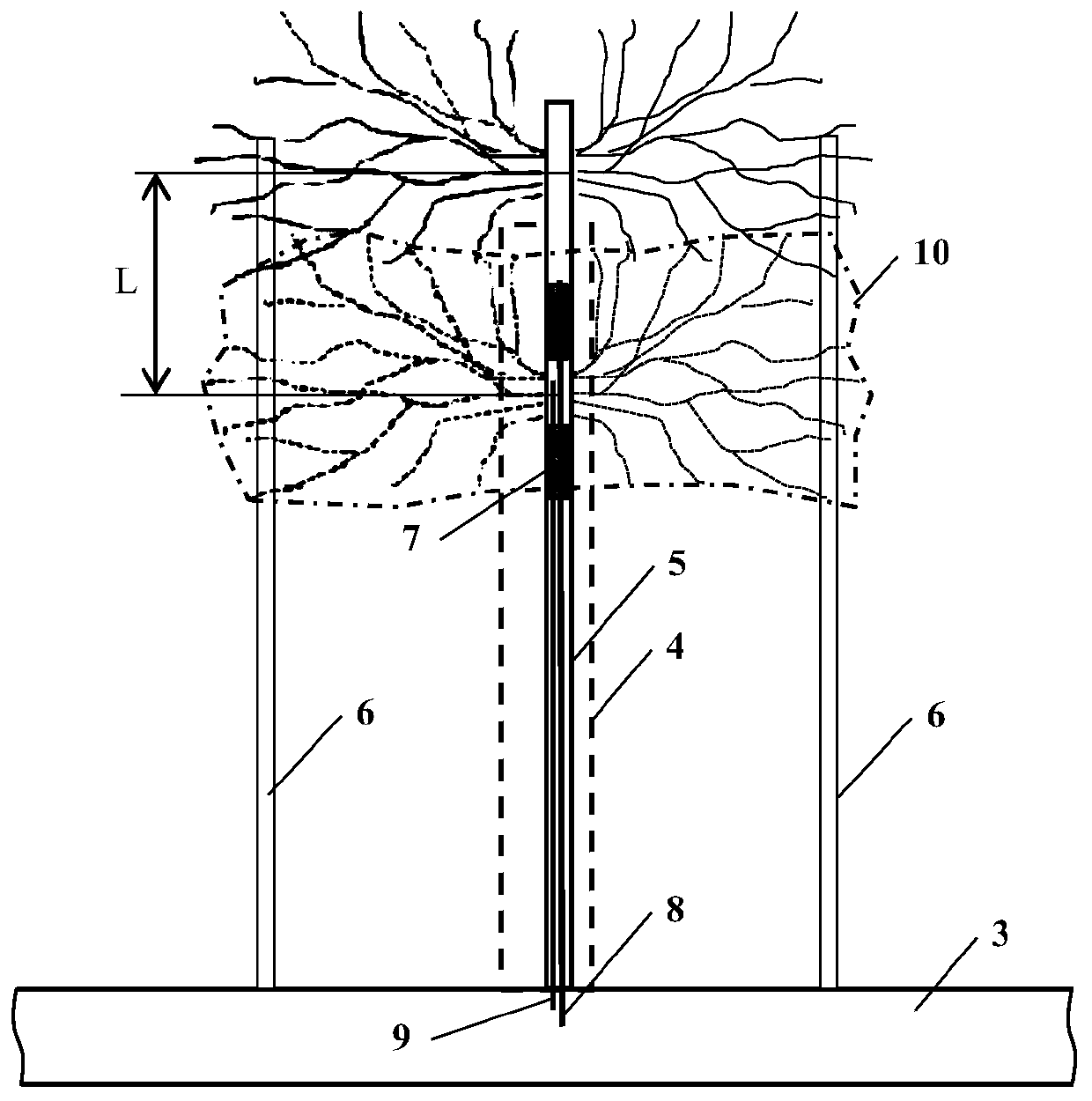

[0038] Such as figure 1 and figure 2 Shown: regional outburst elimination and drainage of single roadway excavation, using I-type bedding floor long drilling holes segmented step by step fracturing to efficiently drain coal roadway strip gas for regional outburst elimination:

[0039] In the existing roadway 3, in the hard floor rock formation 2 near the coal seam 1 where there is a risk of outburst, the I-type floor bedding borehole 5 is drilled along the direction of the coal seam roadway 4 to be excavated.

[0040] After the drilling is completed, the fracturing water pipe 9 equipped with the movable and reusable double-capsule split hole sealer 7 is placed in the layer-by-layer drilling 5 of the bottom floor, and the double-capsule split hole sealer 7 is extended to the bottom floor along the layer Drill the bottom of hole 5.

[0041] Turn on the high-pressure water pump of the hydraulic fracturing system, adjust the water injection pressure, inject water into the capsu...

Embodiment 2

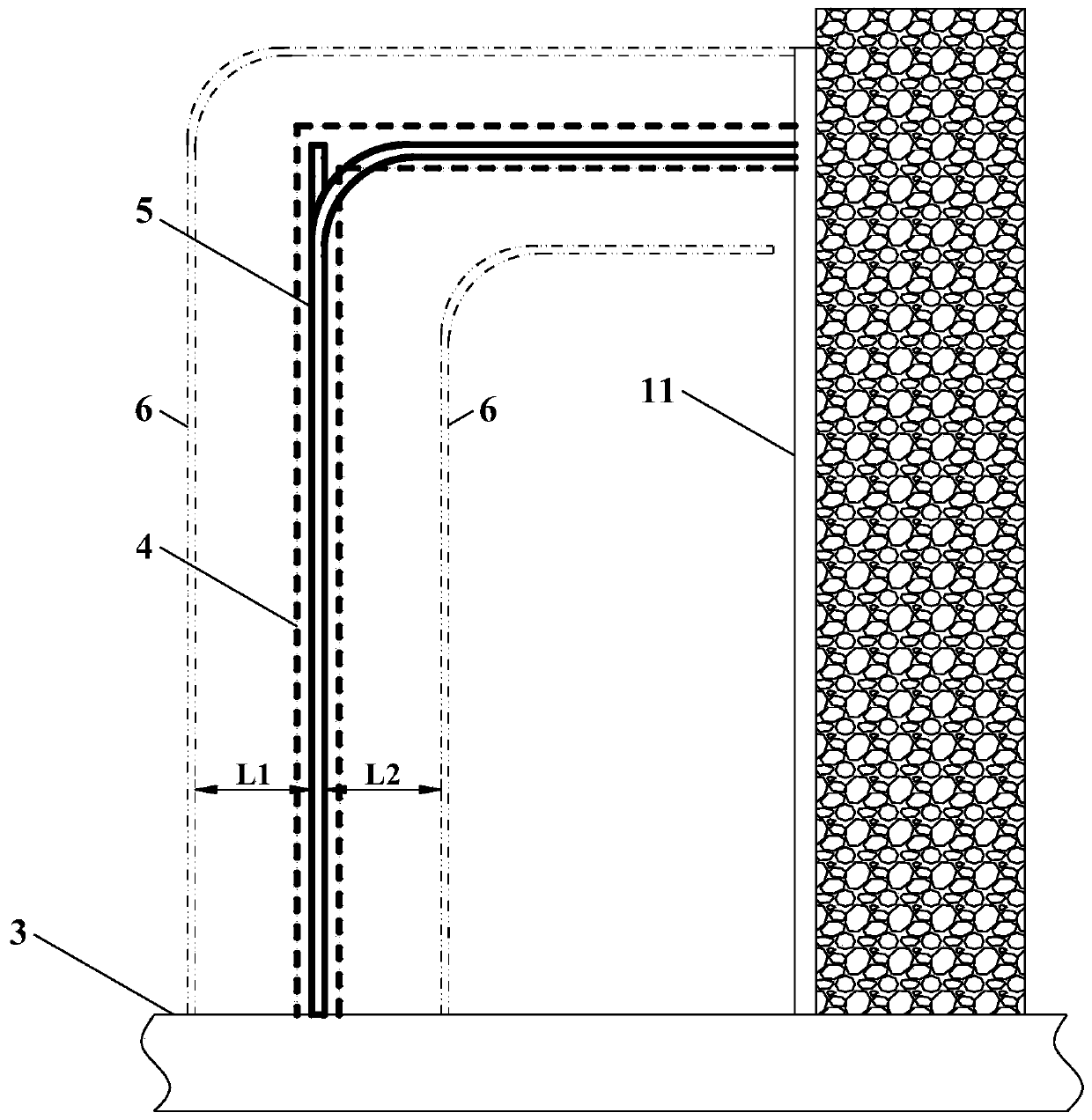

[0045] Such as image 3 As shown, using the regional outburst reduction and drainage of the roadway and the cut hole of the gob-side entry retaining working face, that is, the L-shaped bedding floor long drilling hole is staged and staged to efficiently drain the coal roadway and the cut hole strip gas, Perform area deburring:

[0046] Firstly drill the I-type bedding floor long hole 5 from the roadway 3, and then complete the L-shaped bedding floor drilling 5 at the corresponding position of the cut hole, the distance between the hole bottom and the gob-side entry 11 is not more than 15m; then start from the bottom of the hole Carry out stage-by-stage fracturing on the L-shaped bedding floor drilling holes, and perform gas drainage after fracturing, the same parts as in Example 1 are omitted;

[0047] After the stage-by-stage fracturing is completed, use the L-shaped floor drilling 5 along the bedding to efficiently drain the fracturing anti-reflection area segment by segmen...

Embodiment 3

[0050] Such as Figure 4 Shown: Outburst elimination and drainage in the mining face roadway and cut hole area of double roadway excavation, using L+I type bedding floor long drilling hole segmented step by step fracturing to efficiently drain coal roadway and cut hole strip gas , perform regional deburring:

[0051] In the existing roadway 3, use two drilling rigs to drill into the hard bottom plate of the coal seam roadway 4 to be excavated respectively. The hole bottom spacing of the holes 5 is not more than 15m; then the I-type and L-type bedding floor drilling holes 5 are subjected to stage-by-stage fracturing from the bottom of the holes, and the gas drainage is performed after the fracturing, which is the same as in Example 1 Partially omitted;

[0052] After the stage-by-stage fracturing is completed, use the I-type and L-type bottom plate along-bed drilling holes 5 to efficiently drain the fracturing anti-reflection area step by step or the entire segment; judge w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com