Solder paste stirring equipment used in electronic product manufacturing

A technology for electronic products and stirring equipment, which is used in mixer accessories, mixers with rotary stirring devices, and dissolution, and can solve the problems of low stirring efficiency and complicated operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

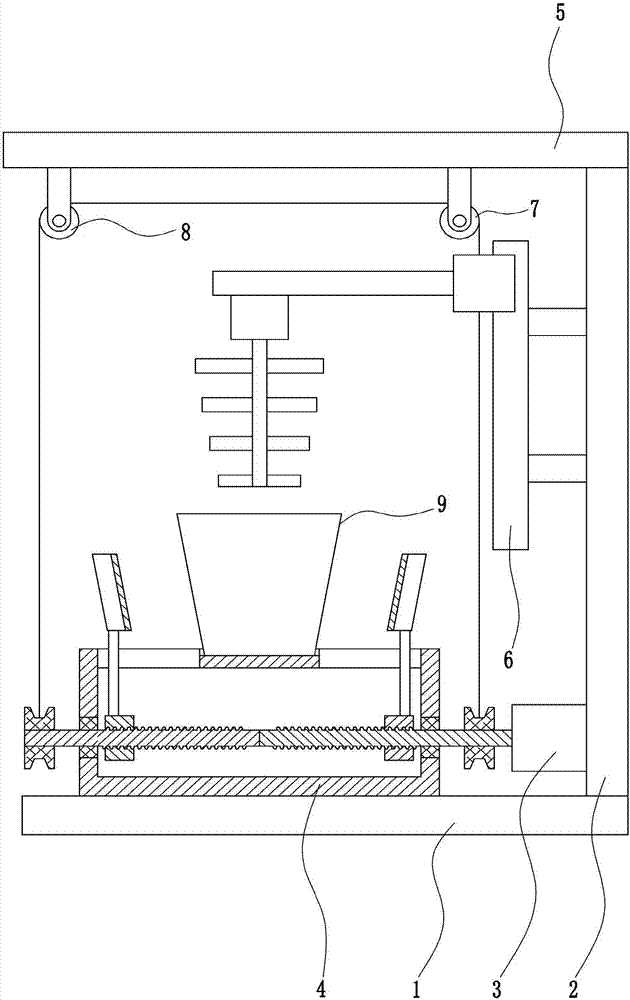

[0030] A solder paste mixing equipment used in the manufacture of electronic products, such as Figure 1-5 As shown, it includes a bottom plate 1, a right frame 2, a first motor 3, a clamping mechanism 4, a top plate 5, a stirring mechanism 6, a first fixed pulley 7 and a second fixed pulley 8, and the right frame 2 is installed on the top right end of the bottom plate 1. , the bottom of the left side of the right frame 2 is equipped with a first motor 3, the top of the bottom plate 1 is equipped with a clamping mechanism 4, the clamping mechanism 4 is connected with the left side of the first motor 3, and the upper left side of the right frame 2 is equipped with a stirring mechanism 6, The top of the right frame 2 is connected with a top plate 5, a first fixed pulley 7 is installed on the right side of the bottom of the top plate 5, a second fixed pulley 8 is installed on the left side of the bottom of the top plate 5, and the solder paste bucket 9 can be placed on the clampin...

Embodiment 2

[0032] A solder paste mixing equipment used in the manufacture of electronic products, such as Figure 1-5 As shown, it includes a bottom plate 1, a right frame 2, a first motor 3, a clamping mechanism 4, a top plate 5, a stirring mechanism 6, a first fixed pulley 7 and a second fixed pulley 8, and the right frame 2 is installed on the top right end of the bottom plate 1. , the bottom of the left side of the right frame 2 is equipped with a first motor 3, the top of the bottom plate 1 is equipped with a clamping mechanism 4, the clamping mechanism 4 is connected with the left side of the first motor 3, and the upper left side of the right frame 2 is equipped with a stirring mechanism 6, The top of the right frame 2 is connected with a top plate 5, a first fixed pulley 7 is installed on the right side of the bottom of the top plate 5, a second fixed pulley 8 is installed on the left side of the bottom of the top plate 5, and the solder paste bucket 9 can be placed on the clampin...

Embodiment 3

[0035] A solder paste mixing equipment used in the manufacture of electronic products, such as Figure 1-5 As shown, it includes a bottom plate 1, a right frame 2, a first motor 3, a clamping mechanism 4, a top plate 5, a stirring mechanism 6, a first fixed pulley 7 and a second fixed pulley 8, and the right frame 2 is installed on the top right end of the bottom plate 1. , the bottom of the left side of the right frame 2 is equipped with a first motor 3, the top of the bottom plate 1 is equipped with a clamping mechanism 4, the clamping mechanism 4 is connected with the left side of the first motor 3, and the upper left side of the right frame 2 is equipped with a stirring mechanism 6, The top of the right frame 2 is connected with a top plate 5, a first fixed pulley 7 is installed on the right side of the bottom of the top plate 5, a second fixed pulley 8 is installed on the left side of the bottom of the top plate 5, and the solder paste bucket 9 can be placed on the clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com