Cloth guide and dehumidification device capable of automatically adjusting tension

A self-adjusting and fabric guiding technology, applied in the directions of transportation and packaging, winding strips, and thin material handling, can solve the problems of fabric wrinkles, poor fabric winding quality, and the influence of fabric flatness, so as to avoid mildew and smoothness. Good quality and ensure the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

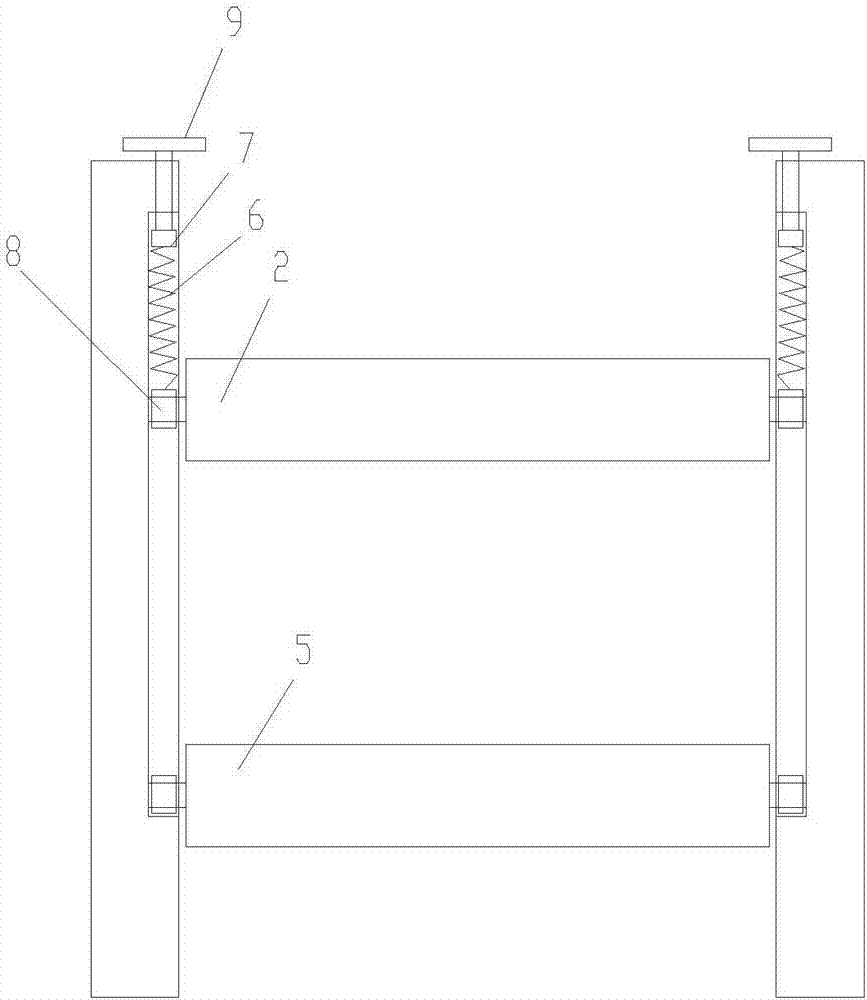

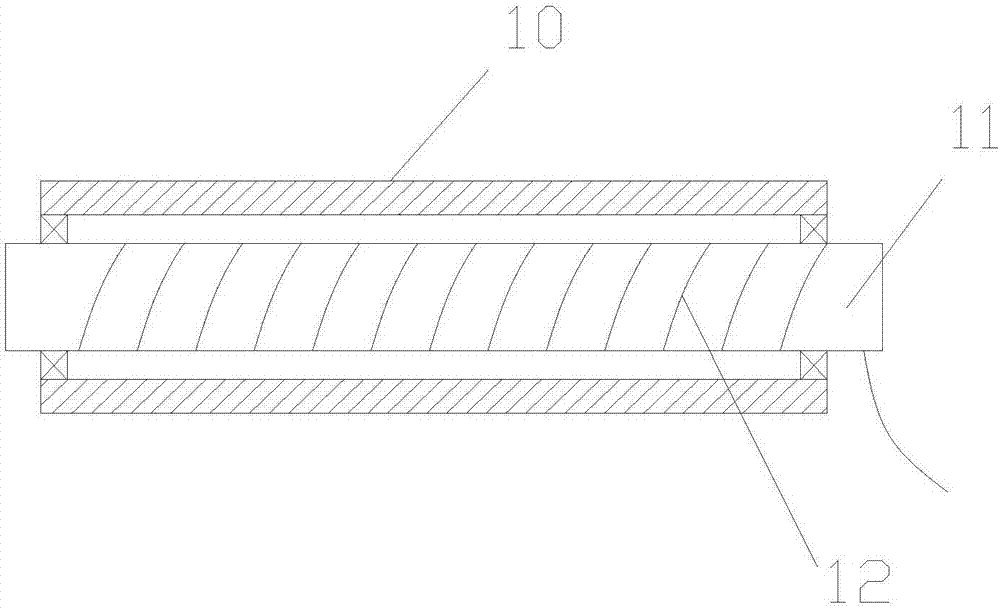

[0018] As shown in the figure: the self-adjusting tension cloth guide dehumidification device of this embodiment includes a front guide roller 1 and a rear guide roller 4, and a tensioning device for tensioning the cloth is arranged between the front guide roller 1 and the rear guide roller 4. Mechanism; Tensioning mechanism comprises frame, is fixed on the fixed roller 5 of frame, is parallel to fixed roller 5 and along vertical direction and the moving roller 2 that slides with frame; The spring 6 that moving roller 2 and fixed roller 5 are far away from each other; The frame is provided with the spring seat 7 that is used to be connected with spring 6; The frame is threaded; in this embodiment, the axes of the moving roller 2 and the fixed roller 5 are located in the same vertical plane. This arrangement can effectively shorten the space occupied by the tensioning mechanism along the horizontal direction and improve the overall weaving device. compactness; in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com