Plastic film punching device

A technology of punching device and plastic film, applied in the field of machinery, can solve the problems of high replacement cost, inability to replace punching needles, different degrees of wear of punching needles, etc., to facilitate disassembly and use, improve work stability and use Longevity and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

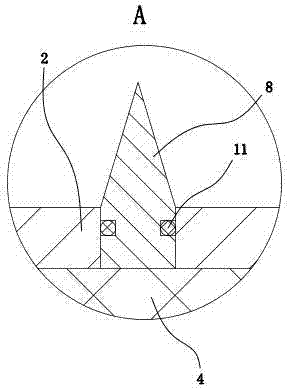

[0026] as shown in the picture 1 As shown, this kind of plastic film punching device consists of a bracket 1 , roller 2 , motor 3 , electromagnet 4 ,sealing plate 5 , battery 6 ,switch 7 , punch needle 8 and so on.

[0027] Among them, the roller 2 The right end is cylindrical and the end is connected to the bracket 1 fixed axially so that the roller 2 able to stand relative to 1 Circumferential rotation. roller 2 right end with a motor 3 connected, and the motor 3 can drive the roller 2 turn. Specifically, the motor 3 The output shaft of the drive is fixed with a driving synchronous wheel, and the roller 2 A driven wheel is fixed on the right end, and a synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com