Automatic motor rotor shaft multi-level component assembling machine capable of achieving accurate machining

A technology for motor rotors and assembly machines, applied to assembly machines, metal processing, metal processing equipment, etc., can solve problems such as installation offset, reduced processing efficiency, and waste of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

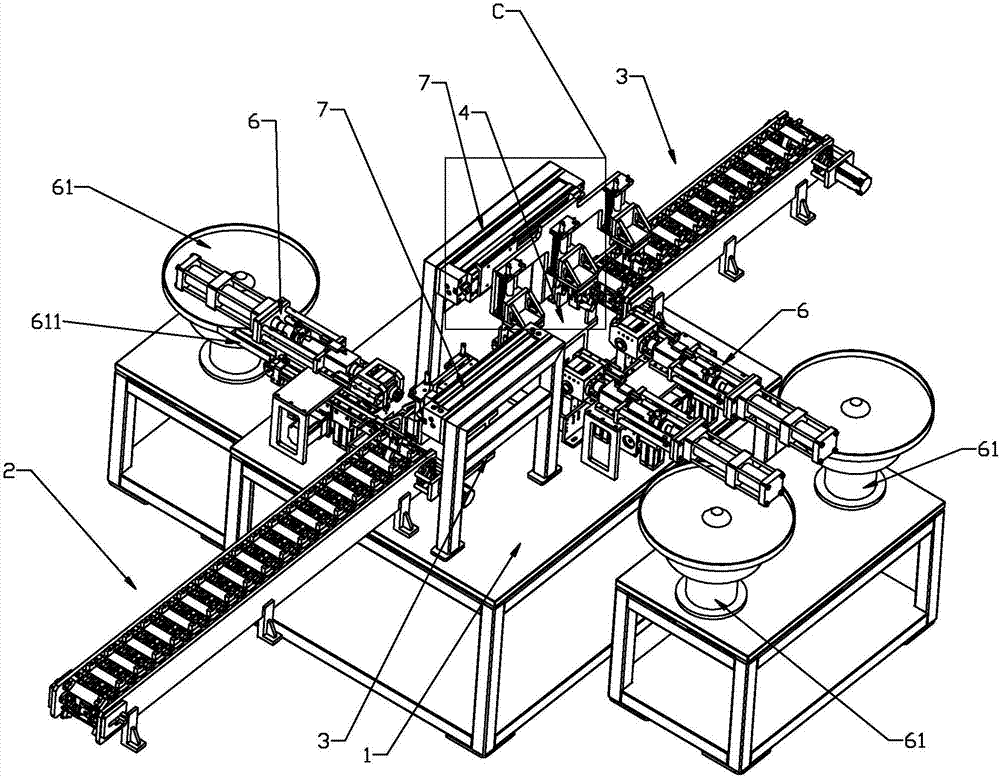

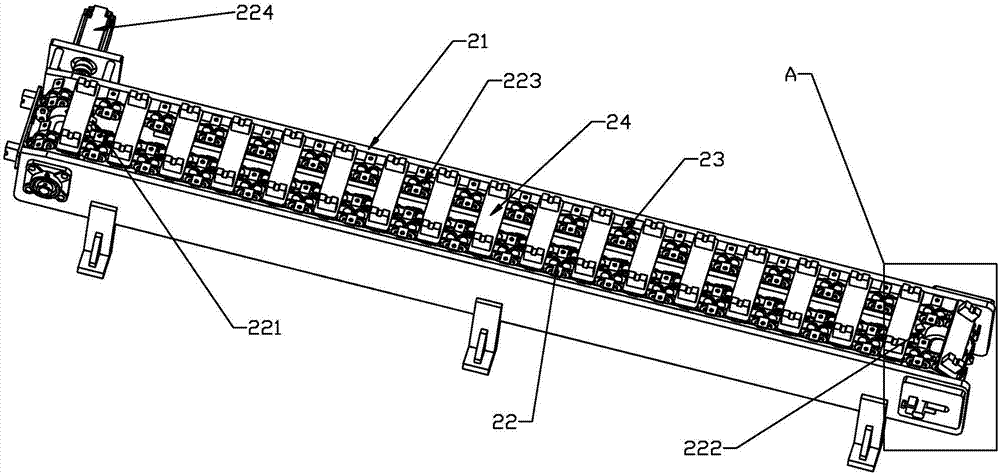

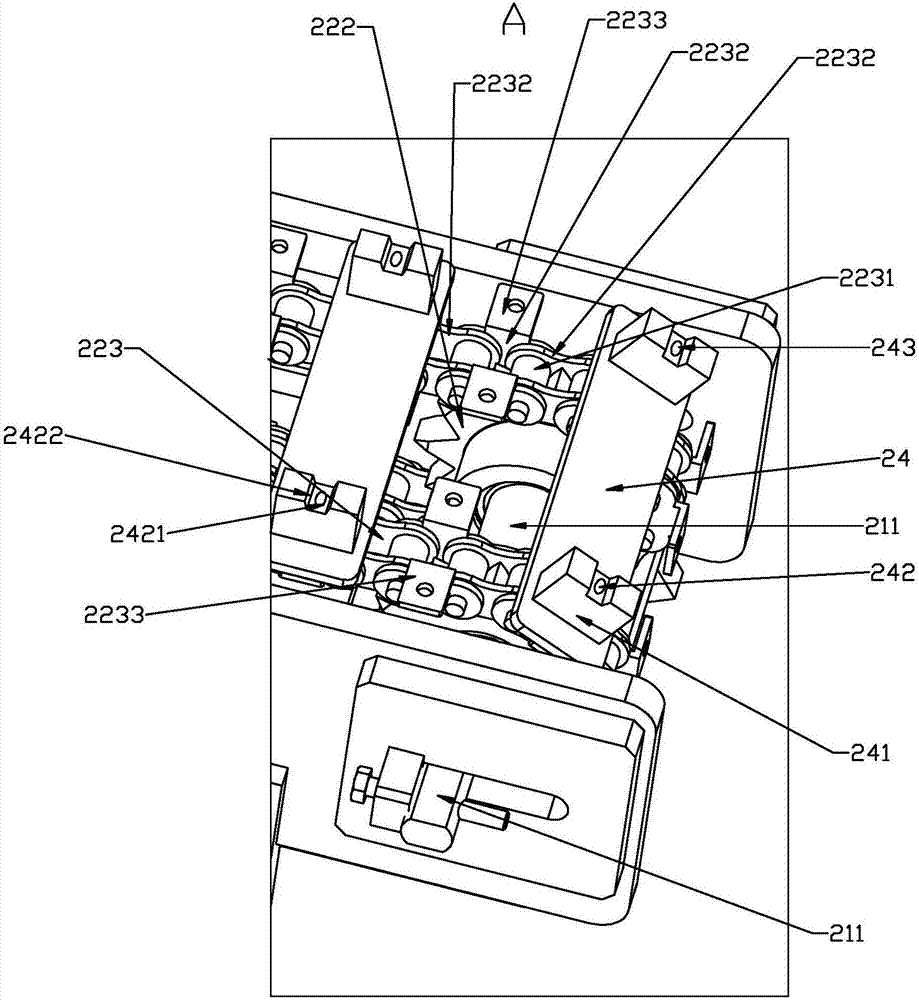

[0033] Such as figure 1 — Figure 10 As shown, the present invention discloses an automatic assembly machine for multi-stage components of motor rotor shaft with accurate processing, which includes a working table 1, on which a feeding device 2, a first processing seat 3, and a second processing seat 4 are sequentially arranged And the discharge device 5, the working surface 1 is located on the side of the first processing seat 3 and the second processing seat 4, and an assembly device 6 is provided. Between the feeding device 2 and the first processing seat 3, a motor rotor shaft is arranged to switch positions in sequence. The front transport device 7, the rear transport device 8 that switches the position of the motor rotor shaft sequentially between the first processing seat 3, the second processing seat 4 and the discharge device 5, the feed device 2 and the discharge device 5 respectively include Track support 21, left gear belt assembly 22, right gear belt assembly 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com