Brushless Direct Current vibration motor

A vibrating motor and brushless technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of enlarging the area of the alveolar metal plate, the motor cannot be driven, and the non-start point, etc., to reduce friction noise and improve stop Speed, the effect of eliminating residual vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to facilitate the implementation of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

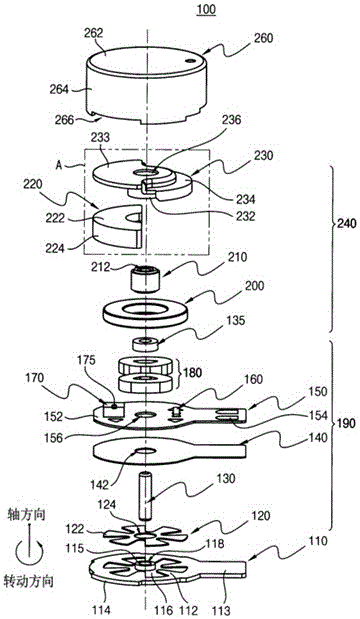

[0065] image 3 is the disassembled state of the components of the BLDC vibration motor (100) in the embodiment of the present invention, Figure 4 It is a cross-sectional view of an assembled BLDC vibration motor (100). The BLDC vibration motor includes a stator (190), a rotor (240), and a casing (110, 260) for accommodating the above two assemblies (190, 240) for protection.

[0066] The upper casing ( 260 ) is sleeve-shaped and has an open bottom. The upper casing ( 260 ) is composed of a circular upper end surface ( 262 ) and side surfaces ( 264 ) bent vertically downward from the edge of the upper end surface ( 262 ).

[0067] The lower casing (110) is composed of a disk portion (112) covering the bottom of the upper casing (260) for sealing and a protruding portion (113) extending horizontally from the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com