Large-aperture three-way sealed switching valve

A large-diameter, switching valve technology, applied in the direction of multi-way valves, valve devices, engine components, etc., can solve problems such as wind grabbing, achieve smooth switching actions, reduce pressure loss, and save valve costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

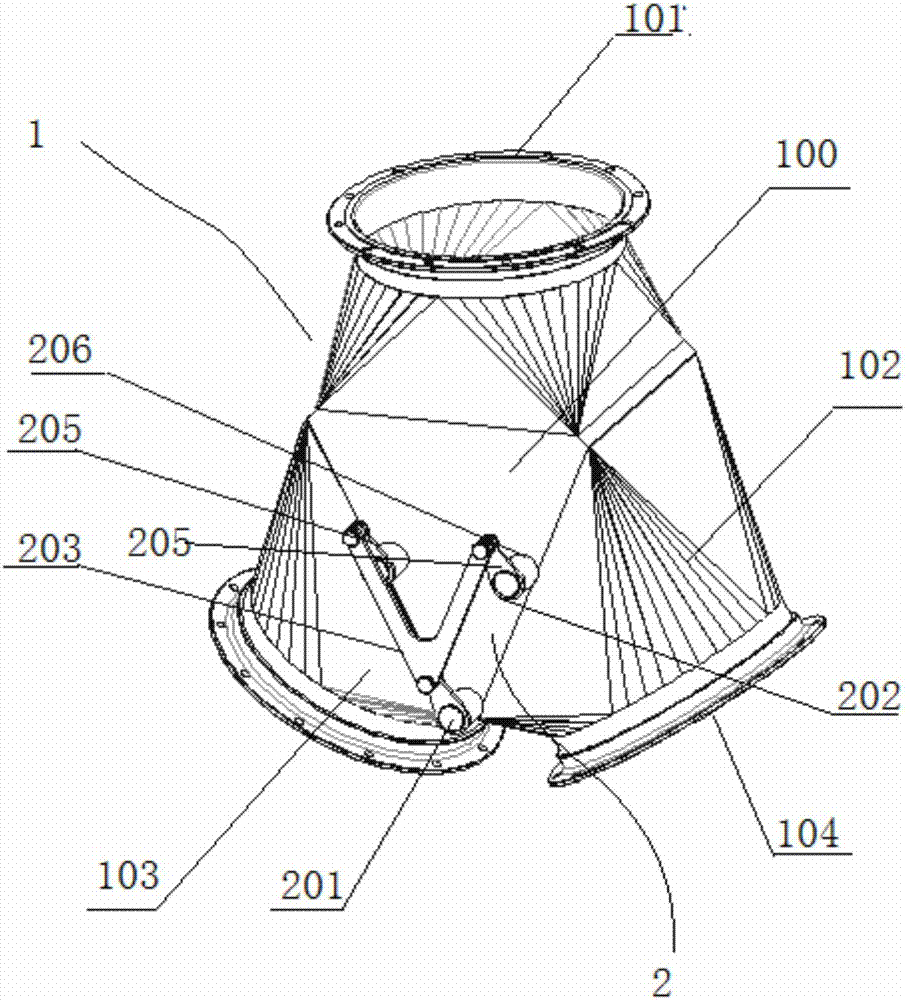

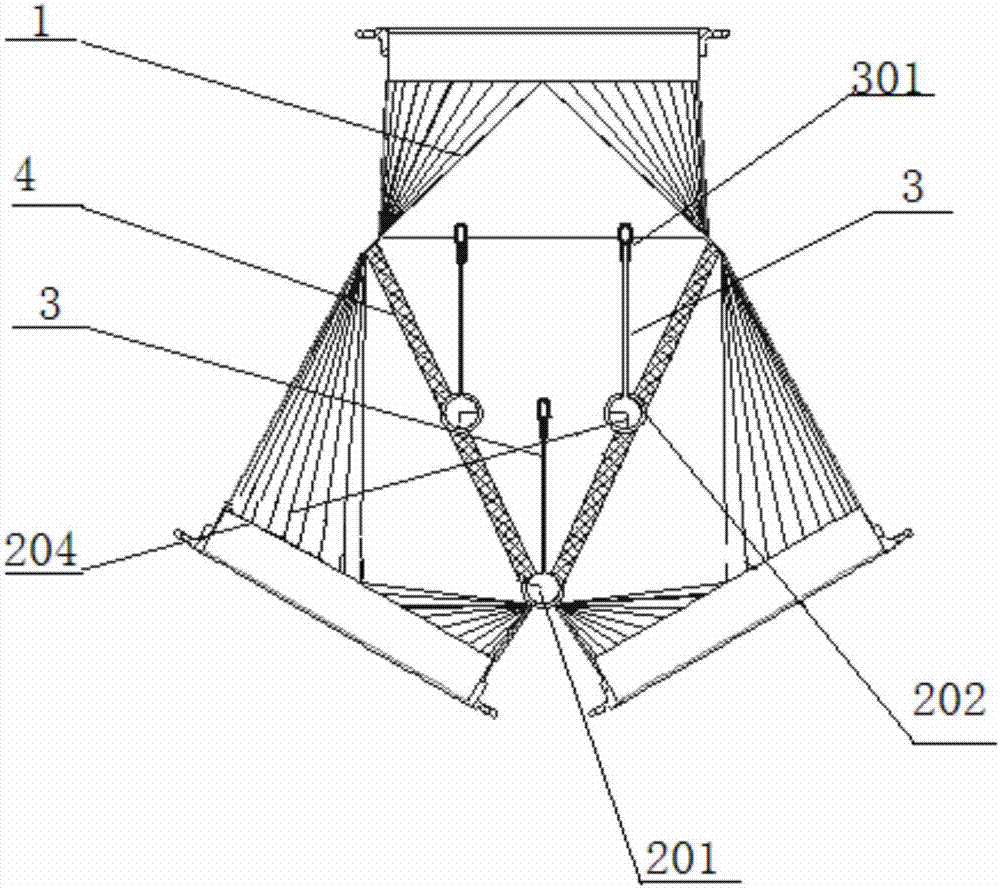

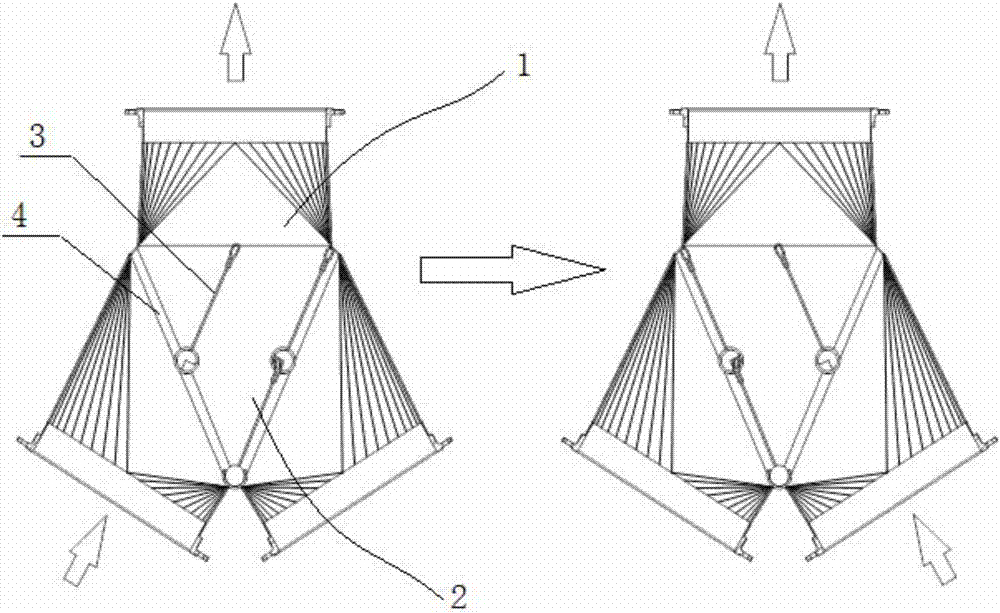

[0034] refer to Figure 1-3 As shown, this embodiment discloses a large-diameter three-way airtight switching valve. The valve can select the number of blades according to the different diameters. The valve adopts a "Y"-shaped three-way as the valve body shape. The through opening is circular or square, and the triangular area in the middle of the through opening must be a symmetrical plane area on both sides, such as figure 1 Valve triangle 100 is shown.

[0035] And, only when the blades are square, can the large-caliber multi-blade processing be realized.

[0036] The structure of the switching valve in this embodiment mainly includes a valve body 1 and a valve assembly 2 cooperating with the above-mentioned valve body 1. The above-mentioned valve assembly 1 is arranged at the air passage opening inside the above-mentioned valve body 1, and the above-mentioned valve body 1 is "Y". The above-mentioned valve body 1 includes three tubular structures, the intersection of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com