A non-weft continuous processing production line

A production line and non-weft fabric technology, applied in the textile field, can solve problems such as low efficiency and unsmooth tearing of the film, and achieve the effect of ensuring accuracy and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

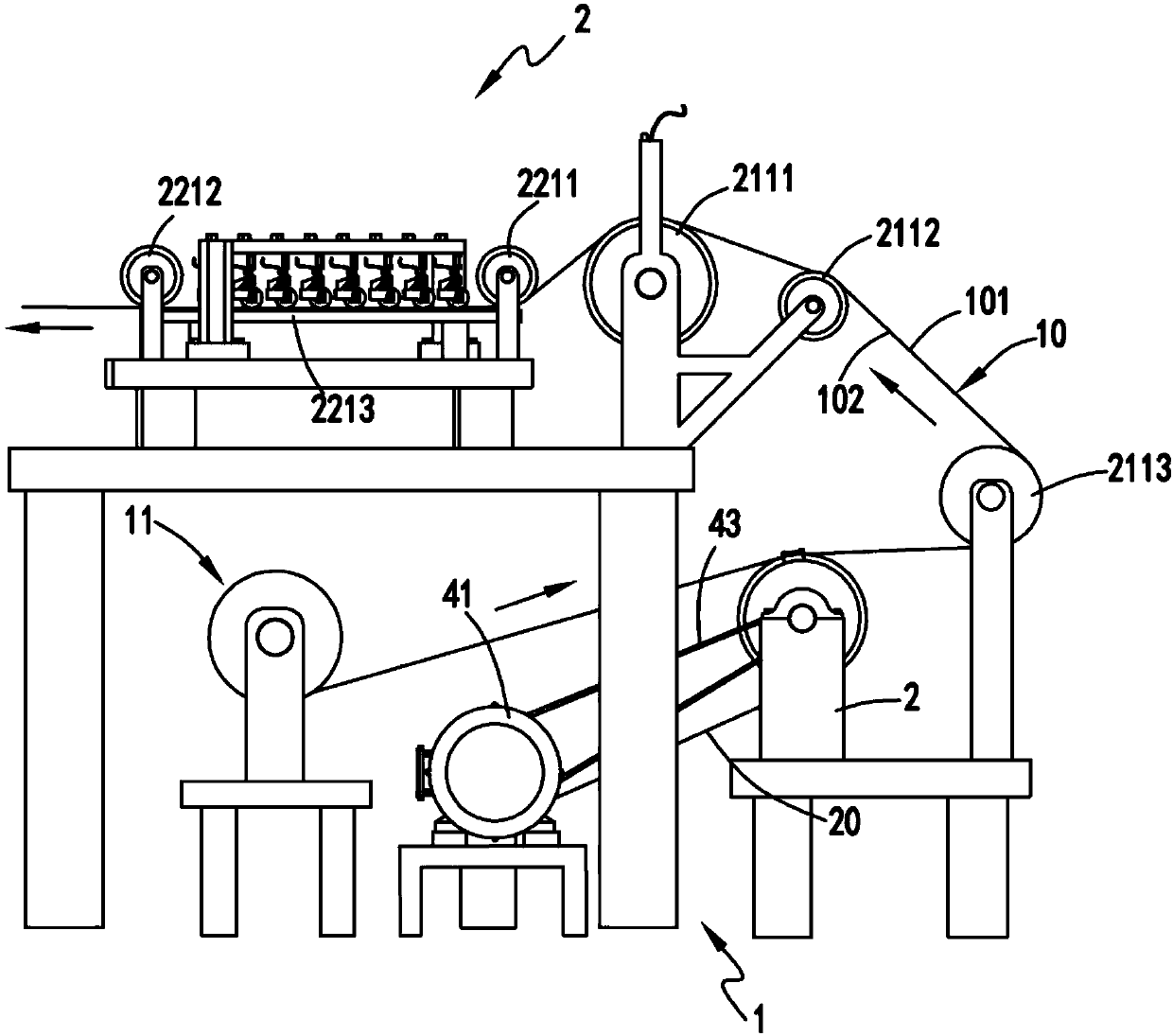

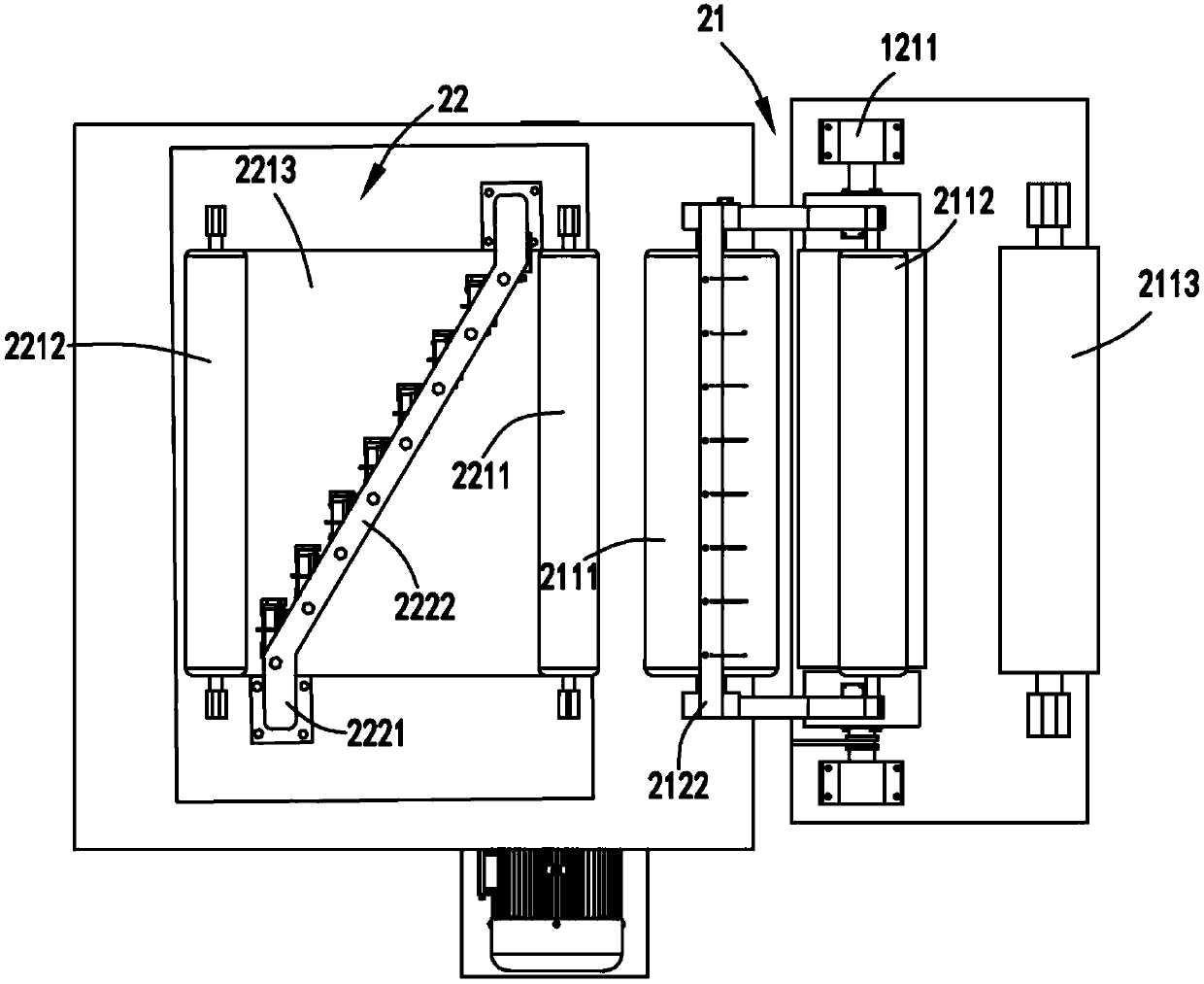

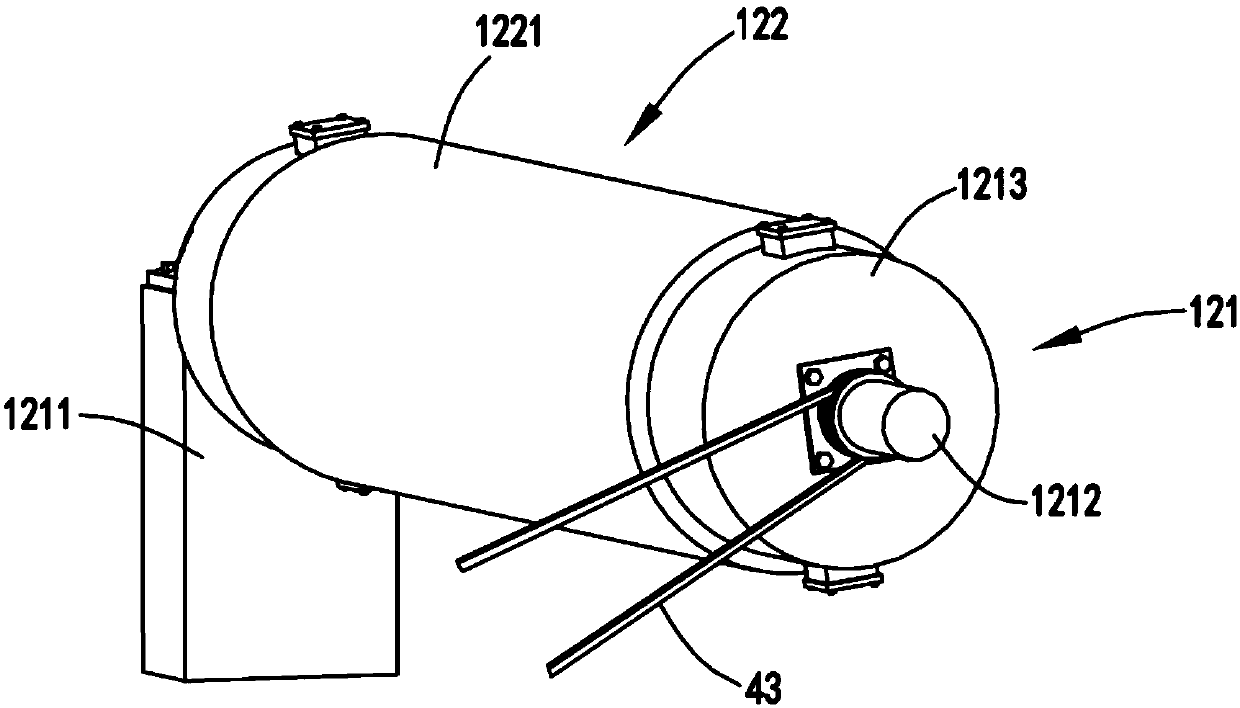

[0052] figure 1 It is a schematic diagram of the front view of the non-weft continuous processing production line, figure 2 It is a top view schematic diagram of the continuous processing line without weft fabric, image 3 Schematic diagram of the structure of the jitter separation mechanism, Figure 4 It is a schematic diagram of the disassembly of the shaking separation mechanism, Figure 5 is a cross-sectional schematic diagram of the vibration separation mechanism, Figure 6 It is a schematic diagram of the structure of the rubber rolling unit, Figure 7 Schematic diagram of the structure when the rubber rolling unit is working, Figure 8 It is a schematic diagram of the structure of the rubber rolling unit in the non-working state, Figure 9 It is a schematic diagram of the structure when the glue outlet hole and the glue guide hole are aligned and connected, Figure 10 It is a schematic diagram of the structure when the glue outlet hole and the glue guide hole are s...

Embodiment 2

[0075] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: one side of the control board 322 is provided with a guide plate 35 for guiding the glue flowing out of the glue box 321 to the glue roller 332; It is also provided with a baffle plate 36 for the end to be attached to the surface of the gluing roller 332 in the non-replenishment state.

[0076] The setting of the guide plate 35 enables the glue flowing out of the glue material box 321 to be directed to the surface of the glue roller 332 in time to ensure a good e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com