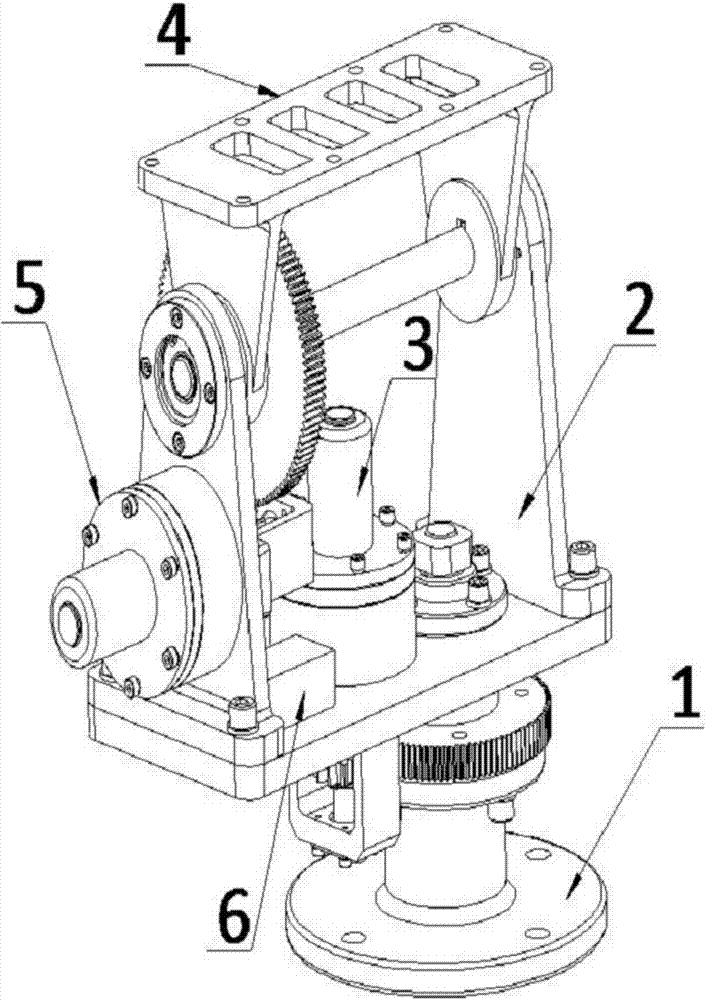

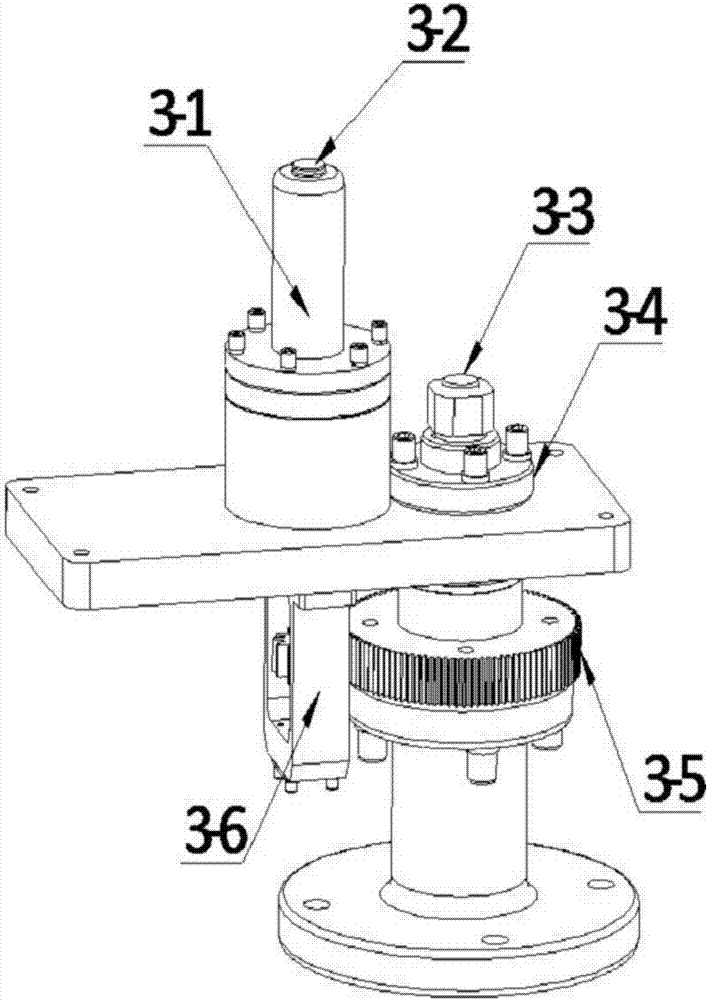

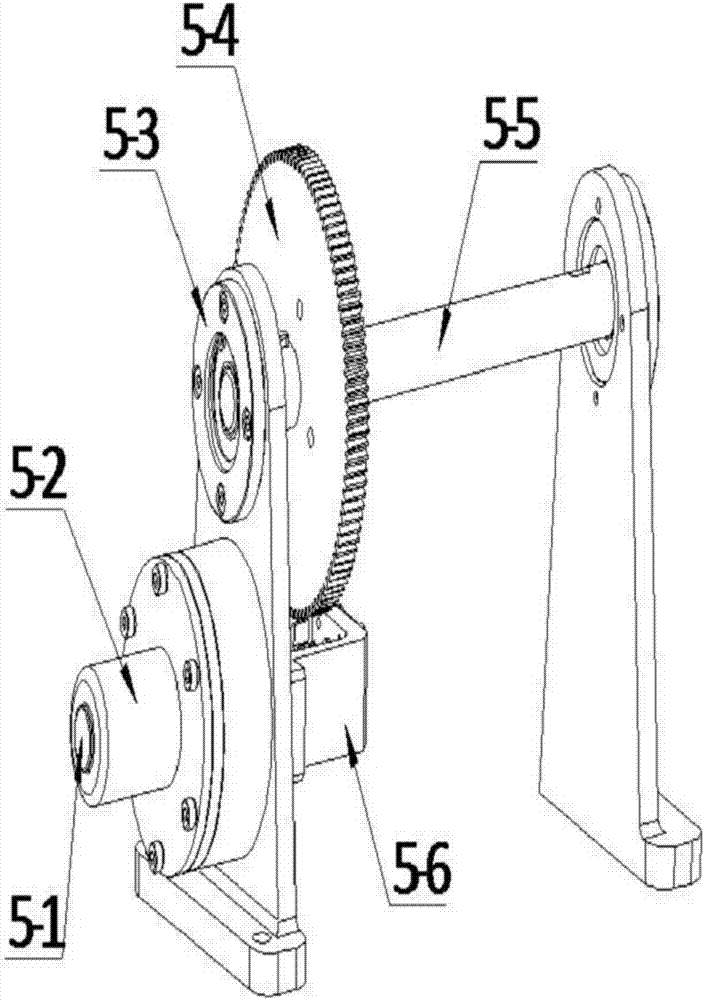

Two-axis grating positioning lifting device for sewage factory and work principle thereof

A technology for positioning lifting devices and sewage plants, which is applied in the direction of use feedback control, etc. It can solve the problems of affecting the normal operation of machinery, transferring suspended solids to the next process, and low positioning accuracy. It is easy to install and maintain, compact in structure, and easy to operate. safe and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Manufacture the side plate 2 of the present invention according to the following steps, and count parts by weight:

[0047] Step 1: Add 1890 parts of ultrapure water with a conductivity of 4.42μS / cm into the reactor, start the stirrer in the reactor at a speed of 98rpm, start the heating pump, and raise the temperature in the reactor to 89°C; add in sequence 234 parts of (1-(4-bromophenyl)piperidin-4-yl)methylcarbamate tert-butyl ester, 2-[(5-amino-6-chloro-1,2,4-thiazine-3- Base)amino]-1-propanol 93 parts, 2-(2-fluoro-2-methylpropyl)pyrrolo[3,4-c]pyrazole-5(2H,4h,6h)-carboxylic acid tertiary 176 parts of butyl ester, stir until completely dissolved, adjust the pH value to 5.94, adjust the speed of the agitator to 141rpm, the temperature is 113°C, and the esterification reaction is 16 hours;

[0048] Step 2: Take 71 parts of methyl 1-methyl-2,4-dioxopiperidine-3-carboxylate, 1-[2-(2-aminoethoxy)ethyl]-1H-pyrrole- 97 parts of 2,5-diketone were pulverized, and the parti...

Embodiment 2

[0053] Manufacture the side plate 2 of the present invention according to the following steps, and count parts by weight:

[0054] Step 1: Add 2460 parts of ultrapure water with a conductivity of 8.68μS / cm into the reactor, start the stirrer in the reactor at a speed of 123rpm, start the heating pump, and raise the temperature in the reactor to 122°C; add in sequence 413 parts of (1-(4-bromophenyl)piperidin-4-yl)methylcarbamate tert-butyl ester, 2-[(5-amino-6-chloro-1,2,4-thiazine-3- Base)amino]-1-propanol 252 parts, 2-(2-fluoro-2-methylpropyl)pyrrolo[3,4-c]pyrazole-5(2H,4h,6h)-carboxylic acid tertiary 265 parts of butyl ester, stir until completely dissolved, adjust the pH value to 7.34, adjust the speed of the agitator to 211rpm, the temperature is 181°C, and the esterification reaction is 28 hours;

[0055] Step 2: Take 244 parts of methyl 1-methyl-2,4-dioxopiperidine-3-carboxylate, 1-[2-(2-aminoethoxy)ethyl]-1H-pyrrole- 242 parts of 2,5-diketone were pulverized, and the ...

Embodiment 3

[0060] Manufacture the side plate 2 of the present invention according to the following steps, and count parts by weight:

[0061] Step 1: Add 2180 parts of ultrapure water with a conductivity of 6.55μS / cm into the reactor, start the stirrer in the reactor at a speed of 110rpm, start the heating pump, and raise the temperature in the reactor to 105°C; add in order 323 parts of (1-(4-bromophenyl)piperidin-4-yl)methylcarbamate tert-butyl ester, 2-[(5-amino-6-chloro-1,2,4-thiazine-3- Base)amino]-1-propanol 172 parts, 2-(2-fluoro-2-methylpropyl)pyrrolo[3,4-c]pyrazole-5(2H,4h,6h)-carboxylic acid tertiary 220 parts of butyl ester, stir until completely dissolved, adjust the pH value to 6.64, adjust the speed of the agitator to 176rpm, the temperature is 147°C, and the esterification reaction is 22 hours;

[0062] Step 2: Take 157 parts of methyl 1-methyl-2,4-dioxopiperidine-3-carboxylate, 1-[2-(2-aminoethoxy)ethyl]-1H-pyrrole- 169 parts of 2,5-diketone were pulverized, and the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com