Vacuum arc-extinguishing-chamber burn-in device of direct-current superposed high voltage pulse and method thereof

A technology of vacuum interrupter and high-voltage pulse, which is applied in the direction of measuring devices, circuit breaker testing, instruments, etc., can solve the difficulty of effectively controlling the aging degree, trend and consistency of aging, and the aging effect of current and voltage cannot be effective Combined with problems such as the inability to accurately adjust the energy of a single aging process, it is easy to break down and aging, the trend and consistency of aging are effective, and the effect of reducing technical difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

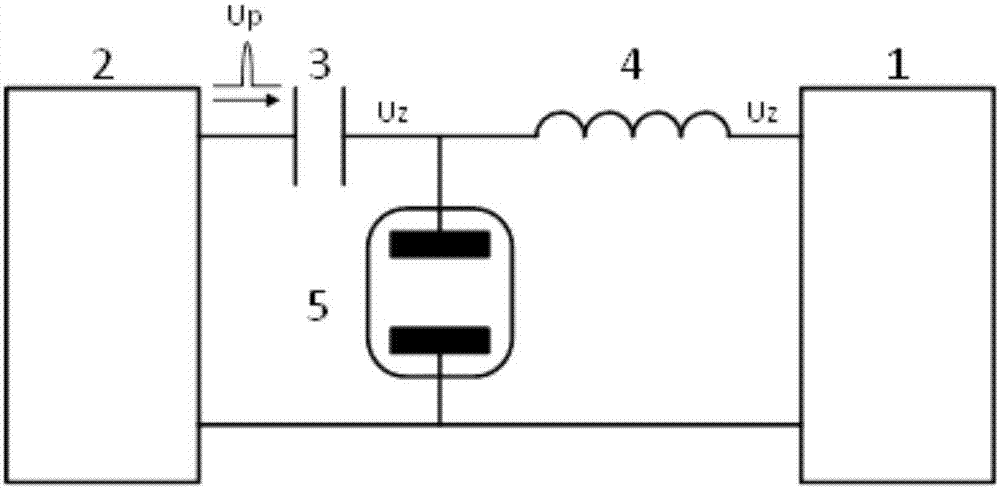

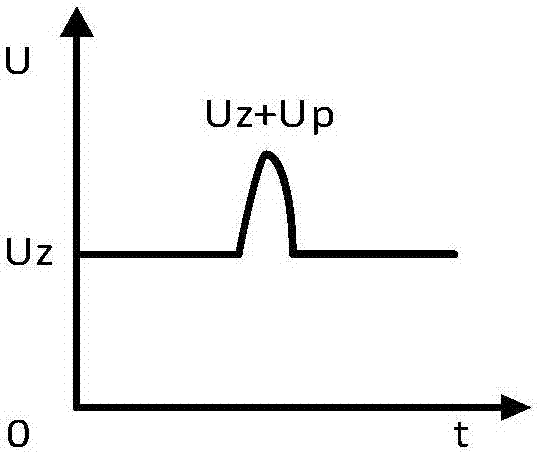

[0020] refer to figure 1 , the DC superimposed high-voltage pulse vacuum interrupter aging device of the present invention includes a DC power supply 1, a pulse power supply 2, a vacuum interrupter 5, a DC blocking coupling capacitor 3 and an isolation inductor 4, one end of the DC power supply 1 and the pulse One end of the power supply 2 is connected to one end of the vacuum interrupter 5 contact, the other end of the DC power supply 1 is connected to one end of the isolation inductor 4, the other end of the pulse power supply 2 is connected to one end of the DC blocking coupling capacitor 3, and the isolation The other end of the direct coupling capacitor 3 and the other end of the isolation inductor 4 are both connected to the other end of the contact of the vacuum interrupter 5 .

[0021] The adjustment range of the voltage value of the DC power output by DC powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com