High-voltage cable pluggable-type intermediate connector for test and cable test device

A technology of high-voltage cables and intermediate joints, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of judgment interference of test results, single structure of intermediate joints, and no plug-in function, etc. Effect of high current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

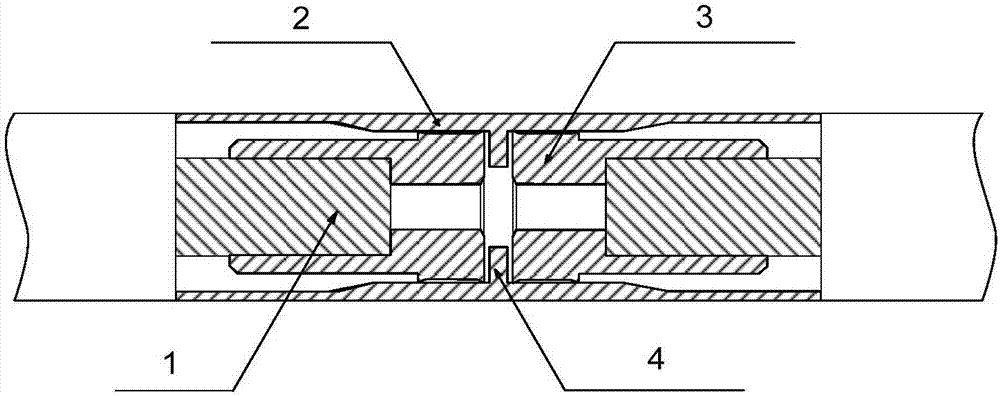

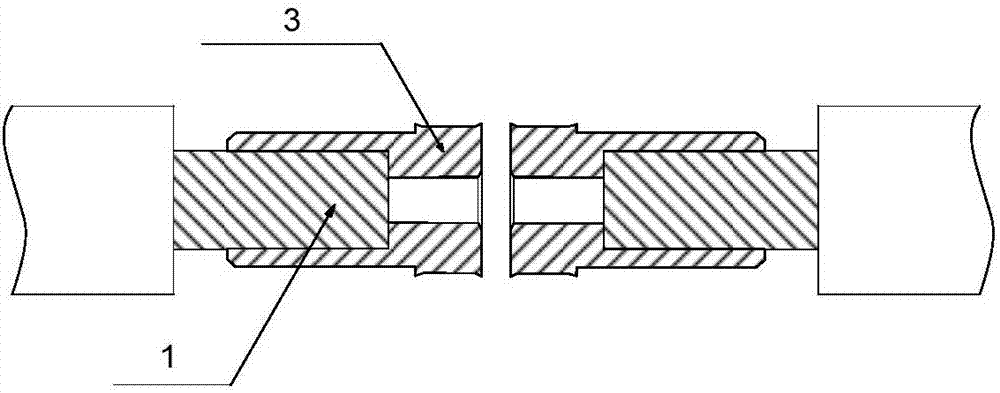

[0024] like Figure 1-2 In the shown high-voltage cable plug-in intermediate connector, the ends of the two cable conductors 1 are covered with a contact 3 . The two contacts 3 are pluggably connected to both ends of the tubular metal shield 2 respectively. A partition 4 for positioning the insertion position of the cable conductor is provided at the middle part of the inner side wall of the metal shielding cover 2 .

[0025] The outer wall of the contact 3 and the inner wall of the metal shield 2 are closely connected by a plurality of bumps, and the plurality of bumps are on the outer wall of the contact 3 . A step that can be positioned and connected to the end of the cable conductor is formed on the inner wall of the contact. The contact 3 is a strap-type contact. The contact is fixedly connected to the cable conductor. The outer end surface of the contact slightly protrudes from the outer surface of the cable conductor. end face.

[0026] The partition 4 is ring-shaped...

Embodiment 2

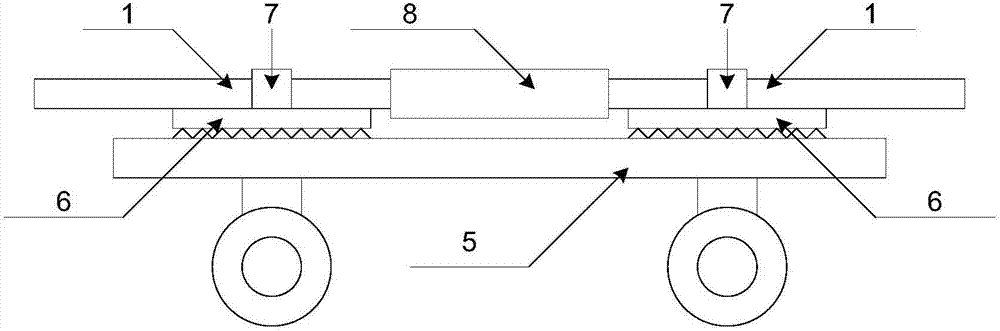

[0028] like image 3 The shown cable test device includes the high-voltage cable plug-in intermediate joint 8 for the test in the first embodiment, the movable base 5 and two metal platforms 6 placed on the base, and the metal platform 6 can move horizontally relative to the base , the metal platform is provided with fasteners 7 for fixing cables; the test high-voltage cable plug-in intermediate joint 8 is located between two metal platforms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com