A method for measuring CO2 concentration distribution and diffusion coefficient in saturated oil porous media

A technology of concentration distribution and diffusion coefficient, which is applied in the direction of measuring devices, material separation, and analysis of materials, etc., can solve the problems affecting the final result and the real state error of the reservoir, achieve accurate test results, eliminate the influence and accuracy of sharp pressure fluctuations high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

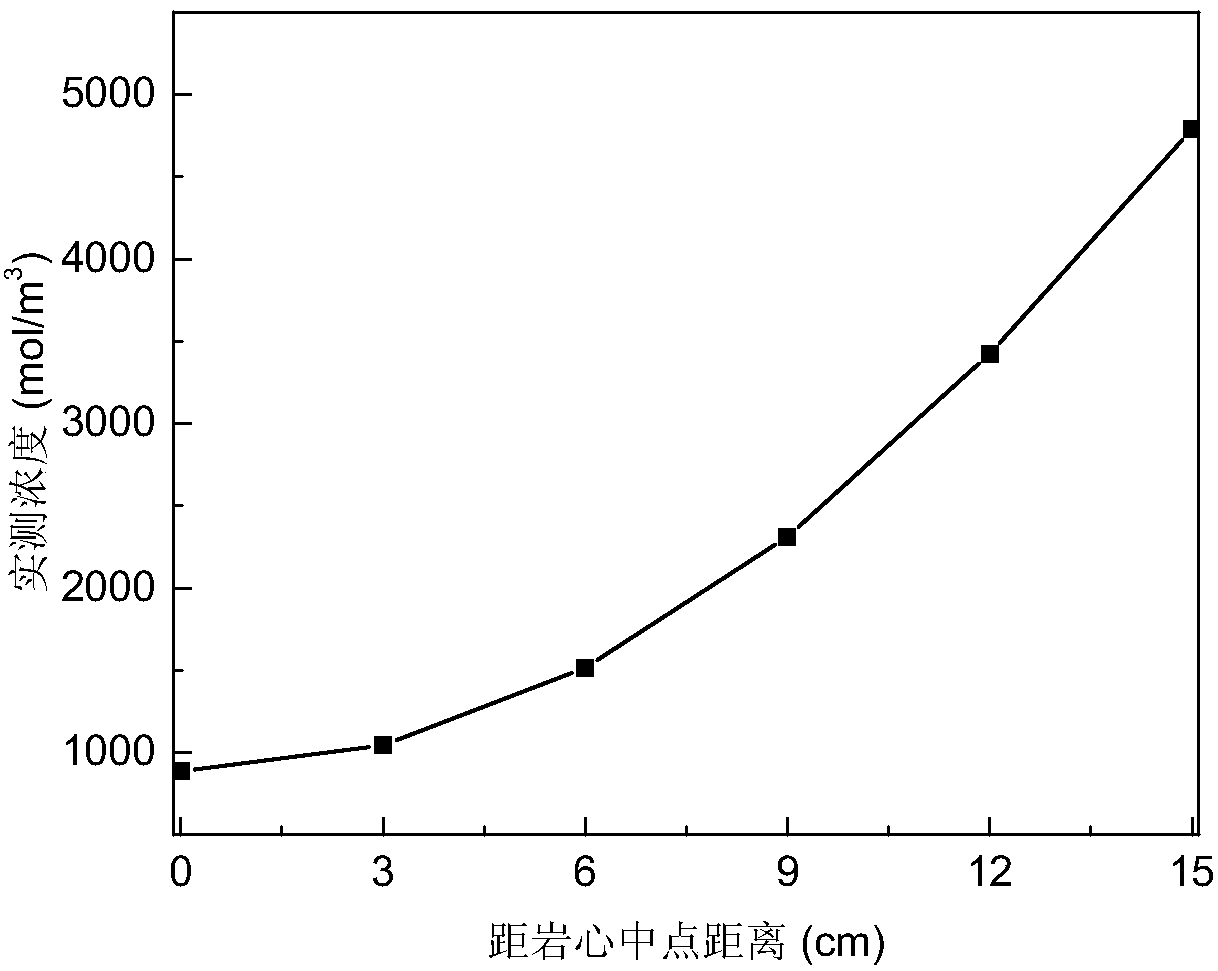

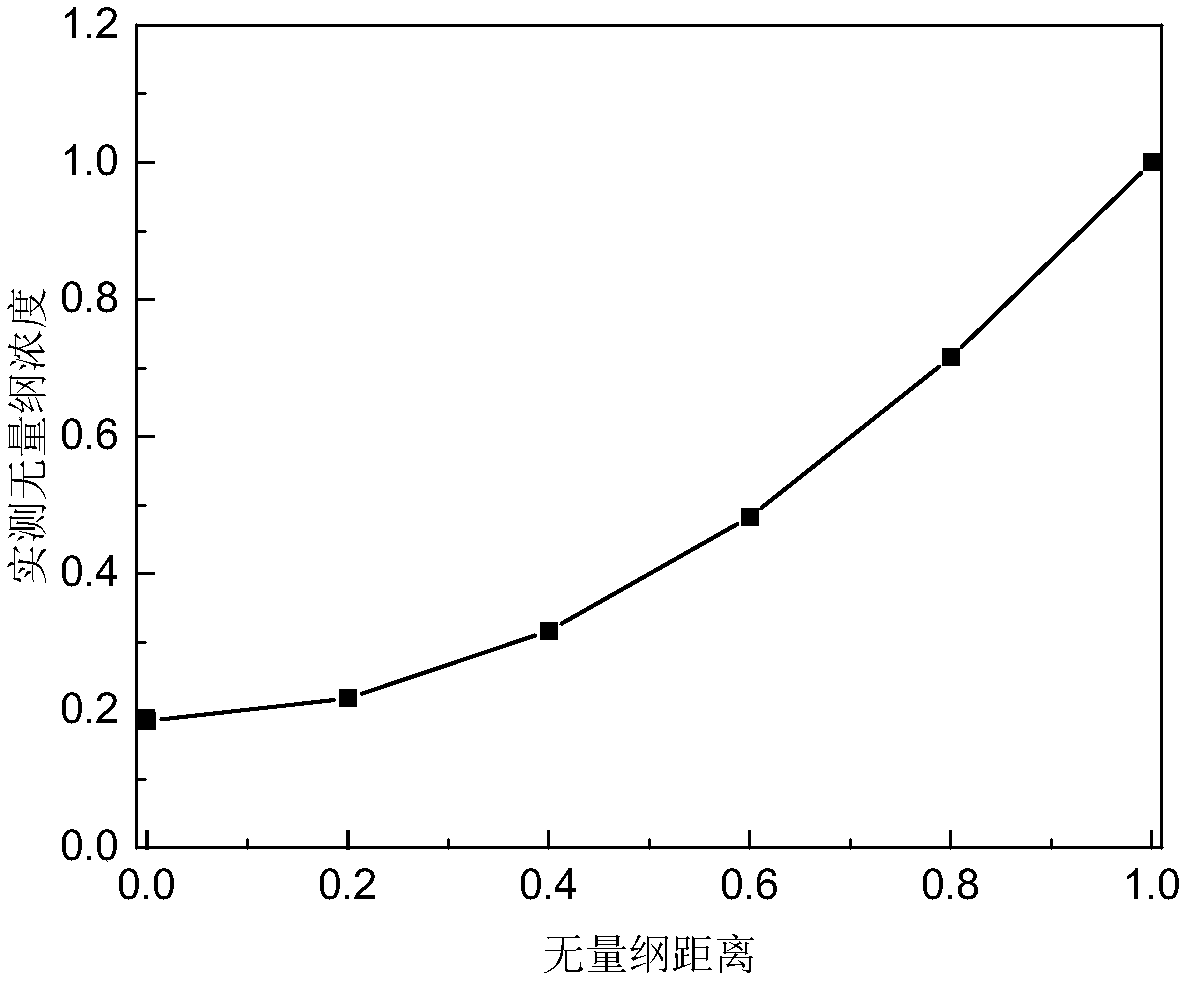

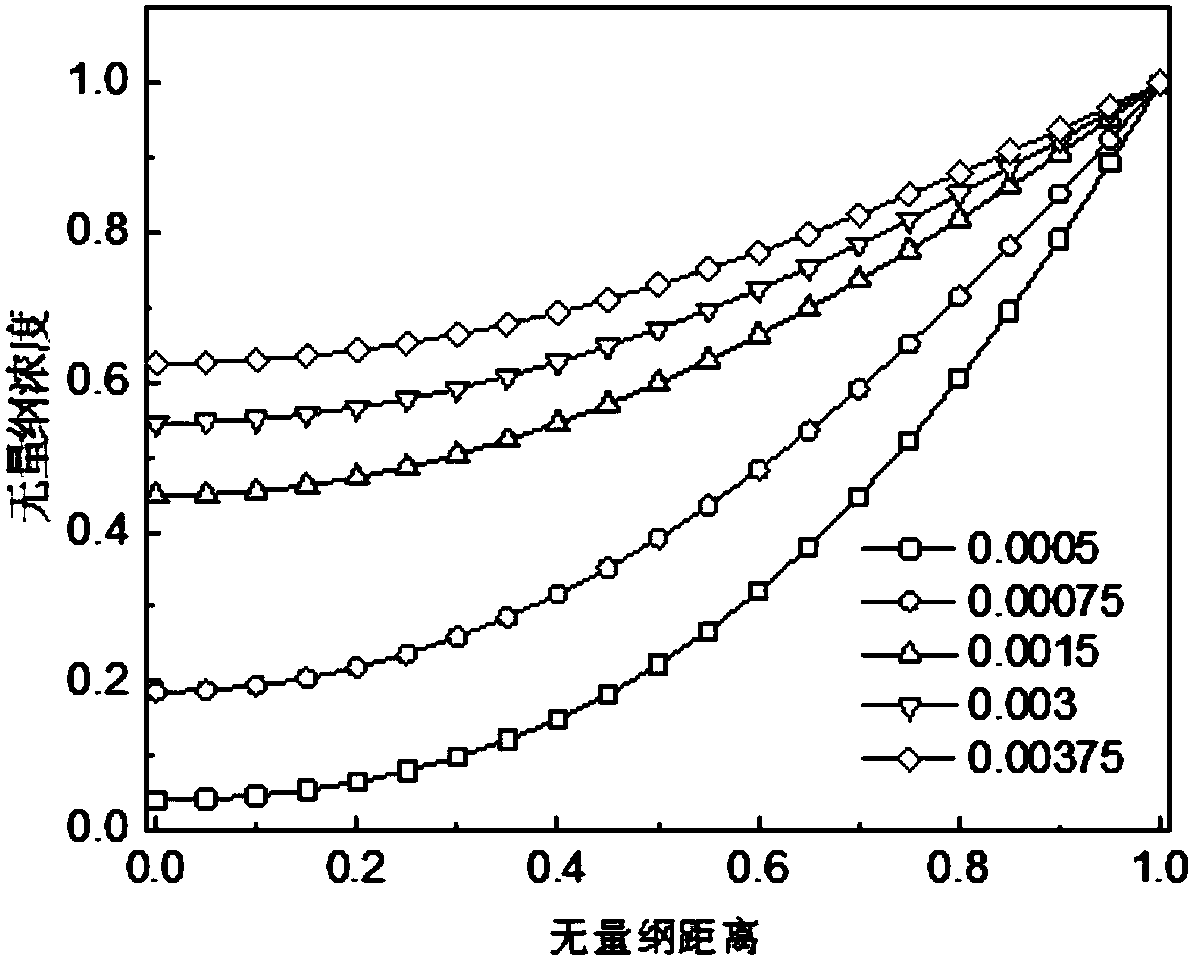

[0043] A method for testing CO in saturated oil porous media 2 The method of concentration distribution and diffusion coefficient includes the following steps:

[0044] 1) CO2 was carried out on the well-saturated oil sample core 2 Axial diffusion, first pretreatment of core saturated oil:

[0045] (1-1) The core holder is cleaned and dried;

[0046] (1-2) Vacuumize the long core to maintain a pressure of 10MPa to saturate the oil.

[0047] Wherein, the core is a rectangular core with a size of 45×45×300 mm.

[0048] Secondly, the axial diffusion of CO in the core 2 The preprocessing of:

[0049] (1-3) Put the core holder into the incubator, and adjust the temperature to the required temperature of 70°C for the experiment, and stabilize for 8-10h;

[0050] (1-4) CO 2 The two ends of the core holder are connected to carry out axial diffusion of the core. During the diffusion process, the gas pressure is always kept stable at the pressure required by the experiment, prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com