Ball slide block measuring device and method

A measuring device and ball-slider technology, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve problems such as affecting the measurement accuracy, and achieve the effects of high measurement efficiency, improved measurement accuracy and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

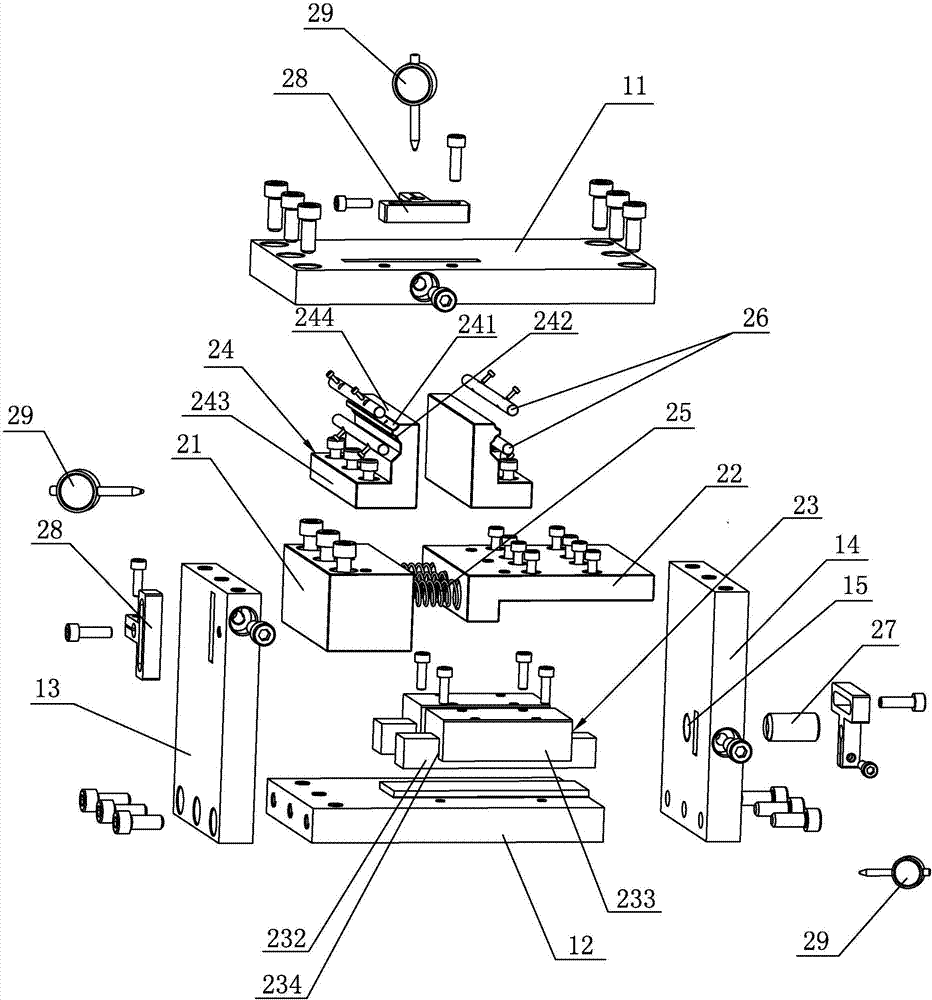

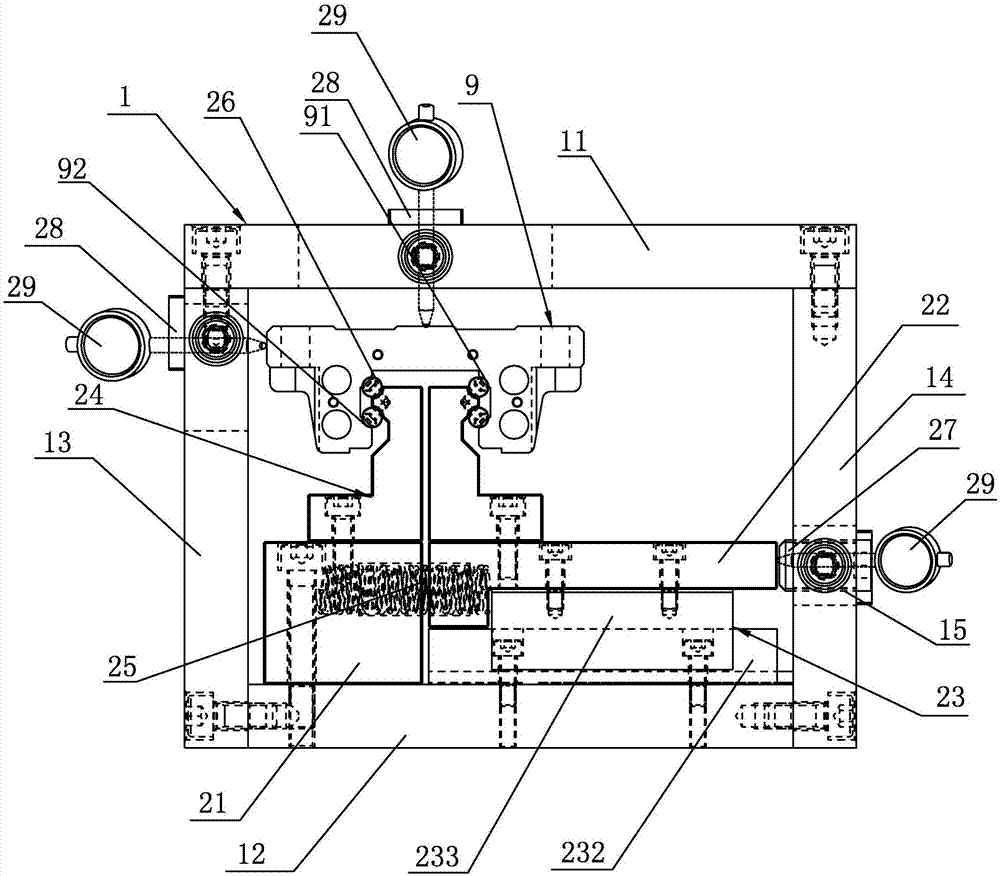

[0022]A measuring device for a ball slider proposed in this embodiment, as shown in the figure, includes a rectangular frame 1 and a slider positioning assembly arranged in the rectangular frame 1. The slider positioning assembly consists of a fixed seat 21, a moving seat 22, The mobile auxiliary part 23 and two measuring heads 24 are formed, the fixed seat 21 is fixed on the left side of the inner bottom surface of the rectangular frame 1, the mobile auxiliary part 23 is arranged on the right side of the inner bottom surface of the rectangular frame 1, and the mobile seat 22 is fixed on the On the moving auxiliary part 23, the top surface of the fixed seat 21 is flush with the top surface of the movable seat 22, and a compression spring 25 is arranged between the opposite inner surfaces of the fixed seat 21 and the movable seat 22, and the two measuring heads 24 are symmetrically fixed on the fixed surface. On the top end surface of the seat 21 and the top end surface of the m...

Embodiment 2

[0030] A method for measuring a ball slider proposed in this embodiment is implemented on the measuring device for a ball slider given in Embodiment 1, and includes the following steps:

[0031] ① Tighten the set screw 27 to make the moving seat 22 move toward the fixed seat 21, the compression spring 25 is compressed, and the distance between the two measuring heads 24 is reduced. When the distance between the measuring rods 26 on the two measuring heads 24 When the spacing is smaller than the spacing between the two upper raceways 91 of the concave-shaped ball slider 9 to be tested, stop tightening the set screw 27 .

[0032] ②Push the concave-shaped ball slider 9 to be tested onto the two measuring heads 24 along the four measuring rods 26, loosen the set screw 27, and under the action of the compression spring 25, the moving seat 22 is far away from the fixed seat 21, The distance between the two measuring heads 24 increases until the measuring rod 26 in the upper arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com