Squeezing mechanism for glue pudding dough drying press

An extrusion mechanism and technology of glutinous rice ball noodles, applied in the field of glutinous rice ball noodles processing, can solve the problems of not being able to clean the material receiving plate in time, troublesome cleaning of the material receiving plate, etc., and achieve the effects of reducing waste, avoiding accumulation, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

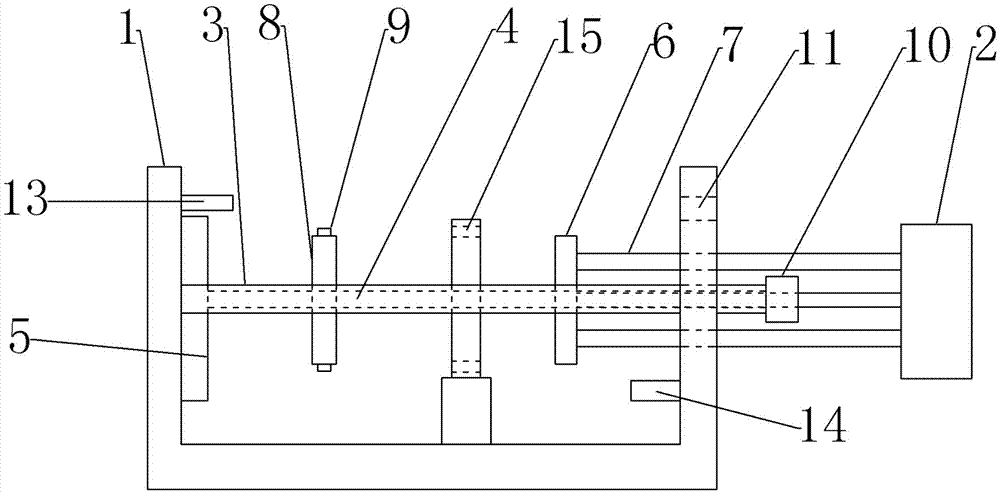

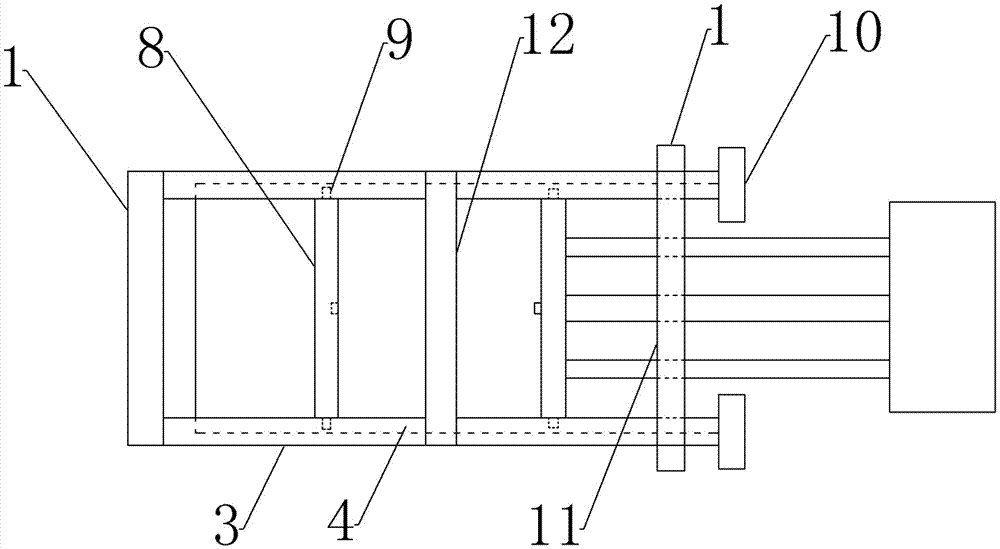

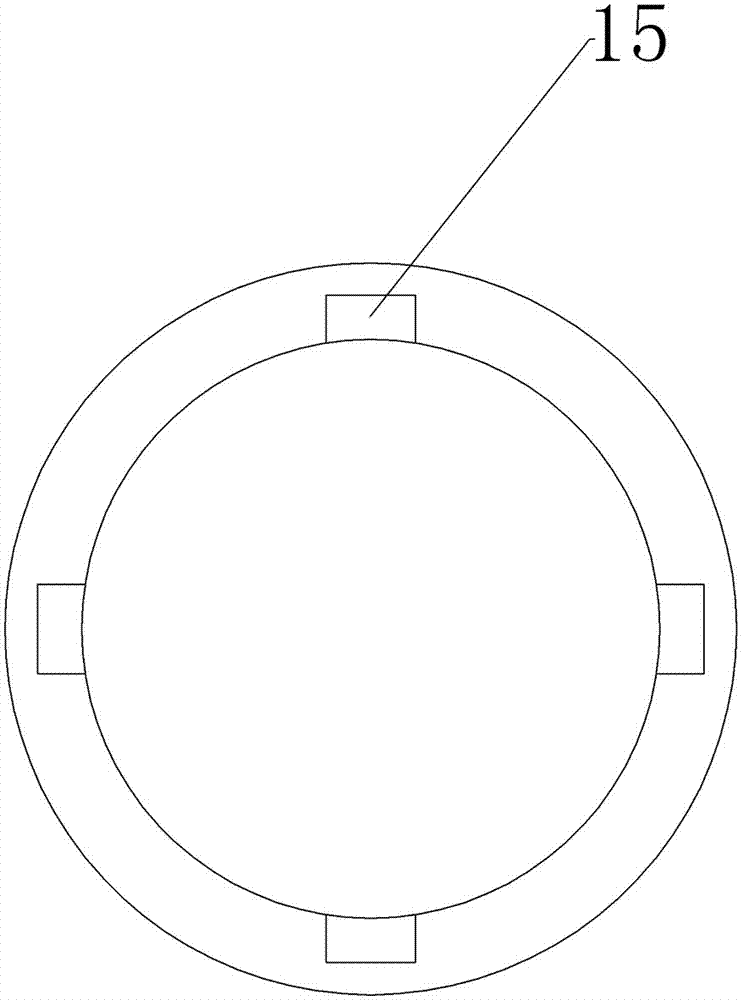

[0024] The reference signs in the drawings of the description include: frame 1, extrusion controller 2, guide rail 3, chute 4, fixed plate 5, sliding plate 6, support rod 7, material receiving plate 8, protrusion 9, positioning plate 10. Stripping claw 11, rotating device 12, upper sprinkler 13, lower sprinkler 14, groove 15.

[0025] This example figure 1 and figure 2 As shown, it includes two pairs of guide rails 3 located on the same horizontal plane, and each guide rail 3 is provided with a chute 4 with the same shape and size. The extrusion zone includes a fixed plate 5 and a guide rail 3 on the left, the left end of the left guide rail 3 is fixedly connected to the fixed plate 5, the stripping zone includes a positioning plate 10 and a guide rail 3 on the right, and the right end of the right guide rail 3 is fixed to the positioning plate 10 connect. A strippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com