Circular-elliptical-non-circular tricycle synchronous belt drive design method

A technology of synchronous belt transmission and design method, which is applied in the directions of transmission, calculation, mechanical equipment, etc., can solve the problems of inconvenient lubrication, inability to ensure real-time tensioning, and low manufacturing cost at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with accompanying drawings and examples of implementation.

[0069] The design method of circular-elliptical-noncircular three-wheel synchronous belt transmission, the specific steps are as follows:

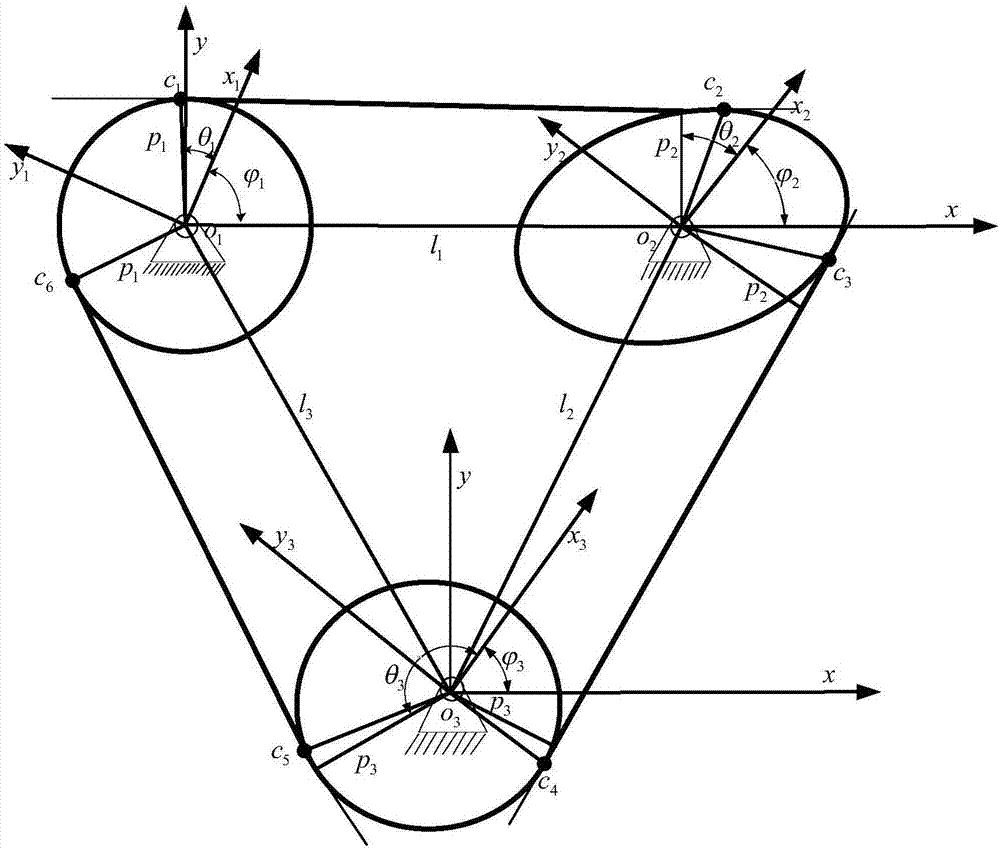

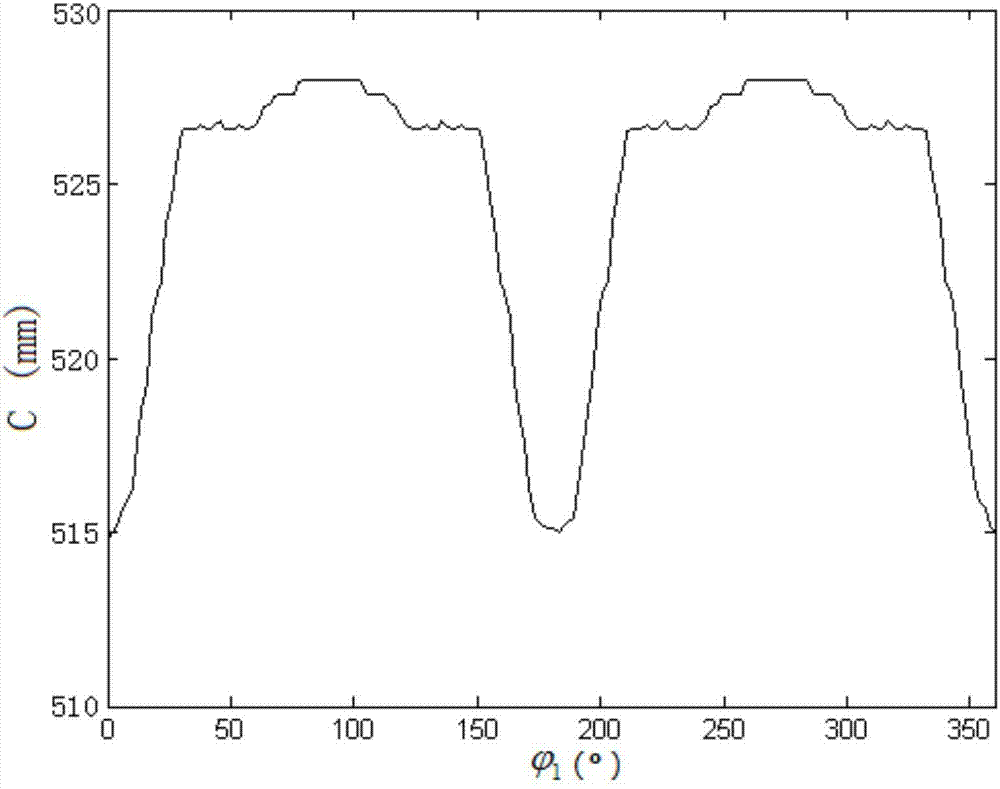

[0070] Step 1, such as figure 1 , given the circular active synchronous pulley pitch curve radius r 1 =30mm, circular active synchronous pulley pitch curve cutting diameter p 1 = r 1 , the tensioned synchronous pulley is a non-circular pulley fitted according to the variation of the slack in the circumference of the synchronous belt; the center distance of the three pulleys is L 1 = L 2 = L 3 =100mm, the three wheels are closed convex curves with equal perimeter, calculate the perimeter s=188.4956mm of the pitch curve of the circular active synchronous pulley according to the following formula:

[0071] s=2π×r 1 (1)

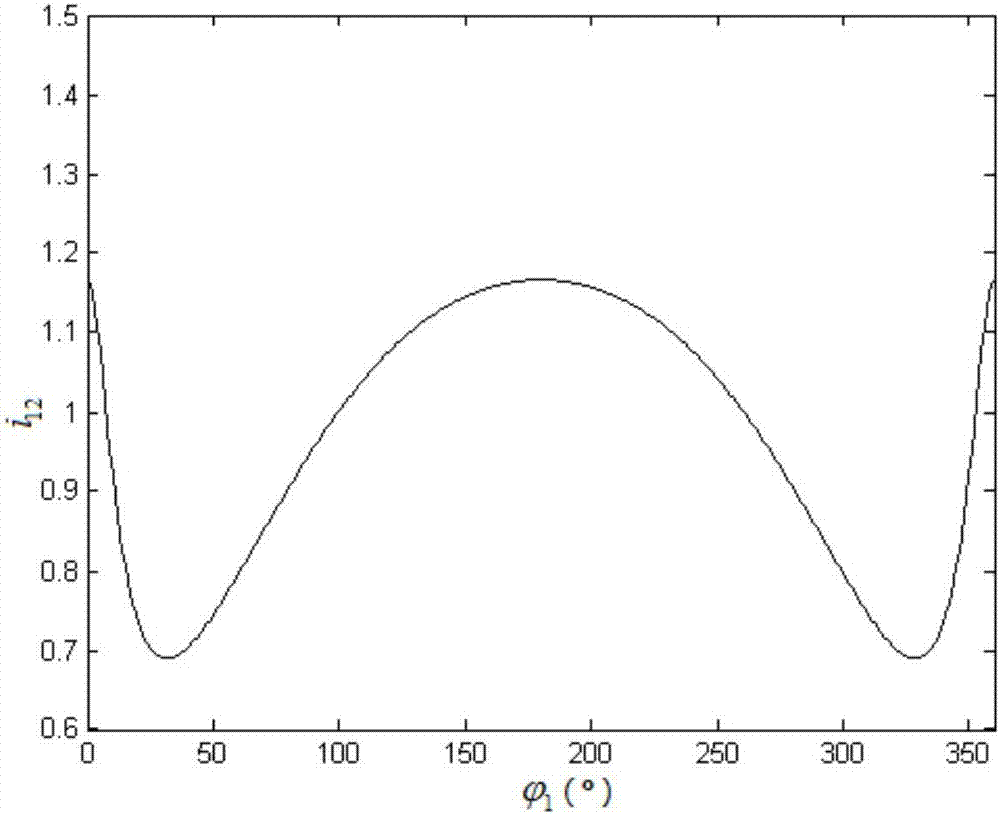

[0072] Step 2. Given the eccentricity e of the pitch curve of the elliptical dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com