A magnetorheological elastomer torsional shock absorber

A magneto-rheological elastomer and torsional shock absorber technology, which is applied in the direction of rotation vibration suppression, non-rotation vibration suppression, vibration suppression adjustment, etc., can solve the problems of narrow adjustment frequency range and poor vibration damping effect, and achieve high work efficiency , avoid resonance, and work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

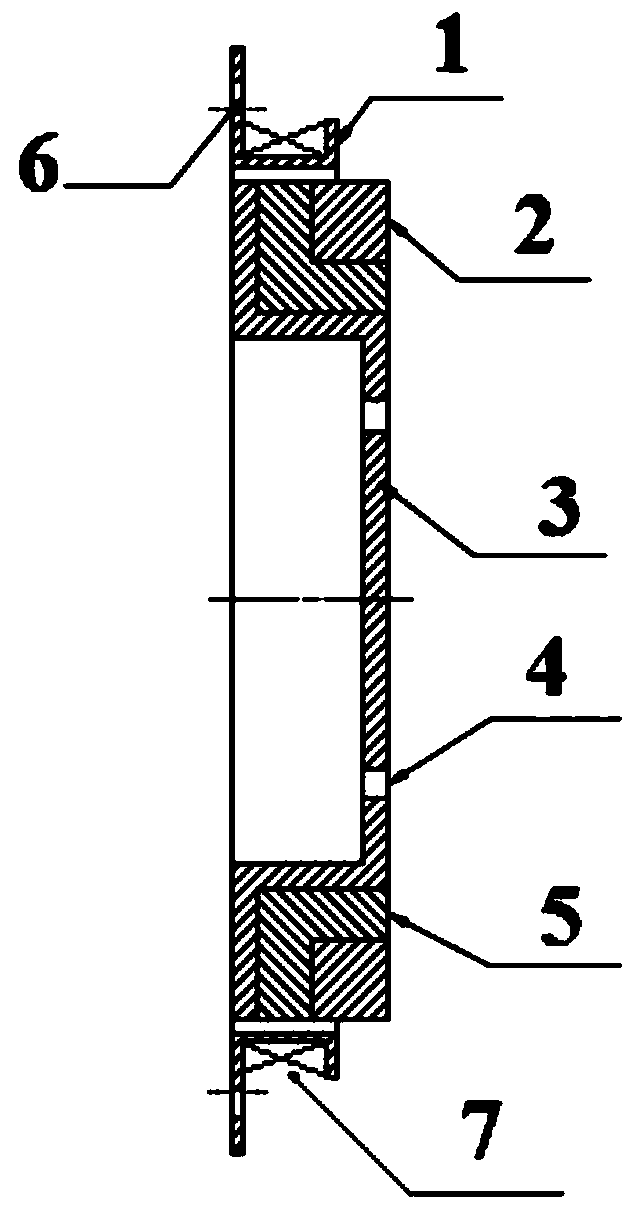

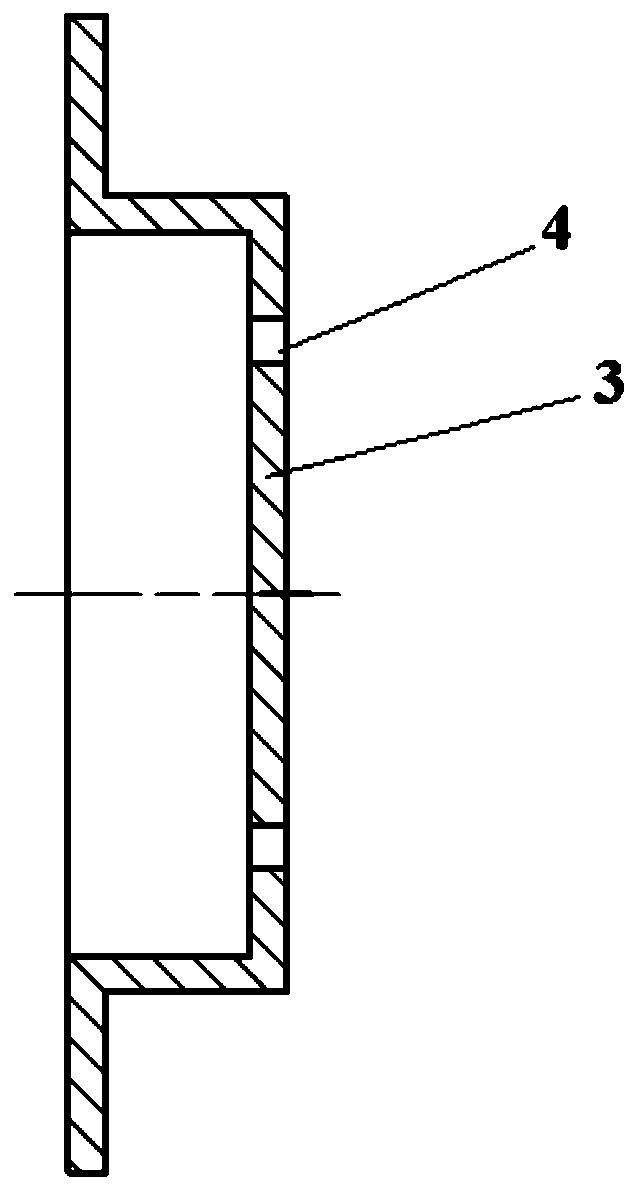

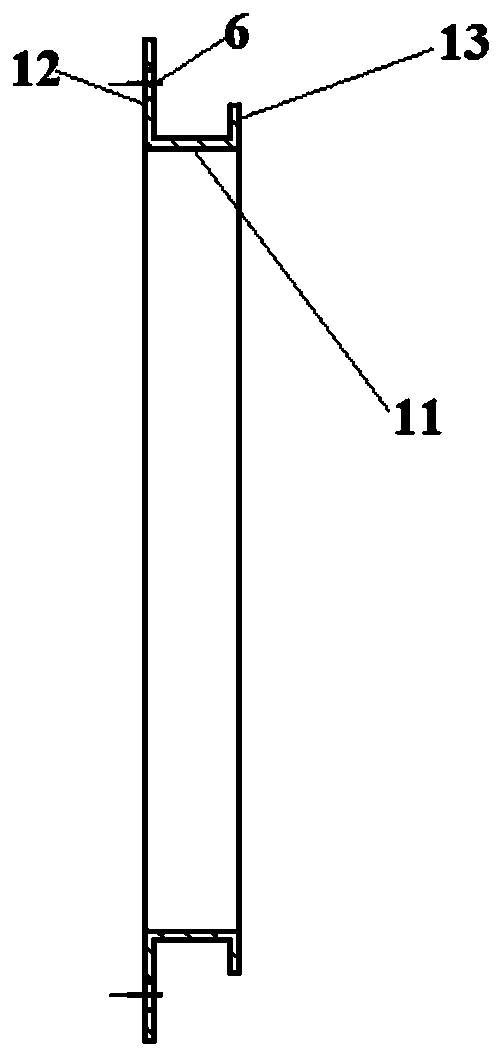

[0029] like Figure 1-4 As shown, a magneto-rheological elastomer torsional shock absorber includes a shock absorber housing 3 fixedly connected to the crankshaft, a coil support 1 sleeved on the outside of the shock absorber housing 3 and fixedly connected to the engine housing, a winding The electromagnetic coil 7 on the coil support 1, the current controller electrically connected to the electromagnetic coil 7, and the magnetorheological elastomer unit sleeved on the shock absorber housing 3 and used in conjunction with the electromagnetic coil 7, in the working state , the current controller adjusts the magnitude of the current of the electromagnetic coil 7, and the electromagnetic coil 7 generates a magnetic field of a corresponding strength, thereby changing the frictional damping of the magnetorheological elastomer unit to consume torsional vibration energy and avoid resonance.

[0030] Wherein, the magnetorheological elastomer unit includes a mass block 2 sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com