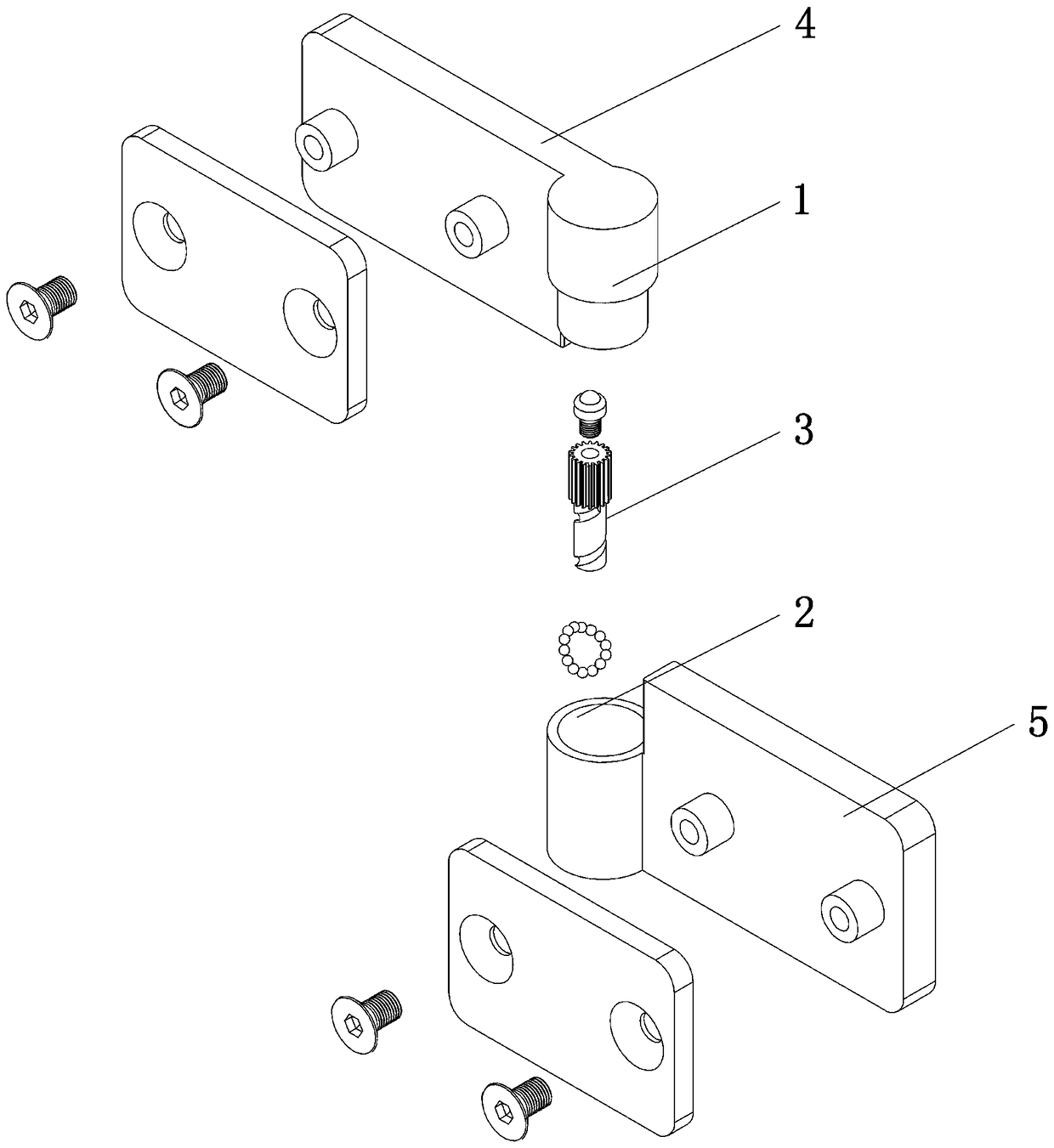

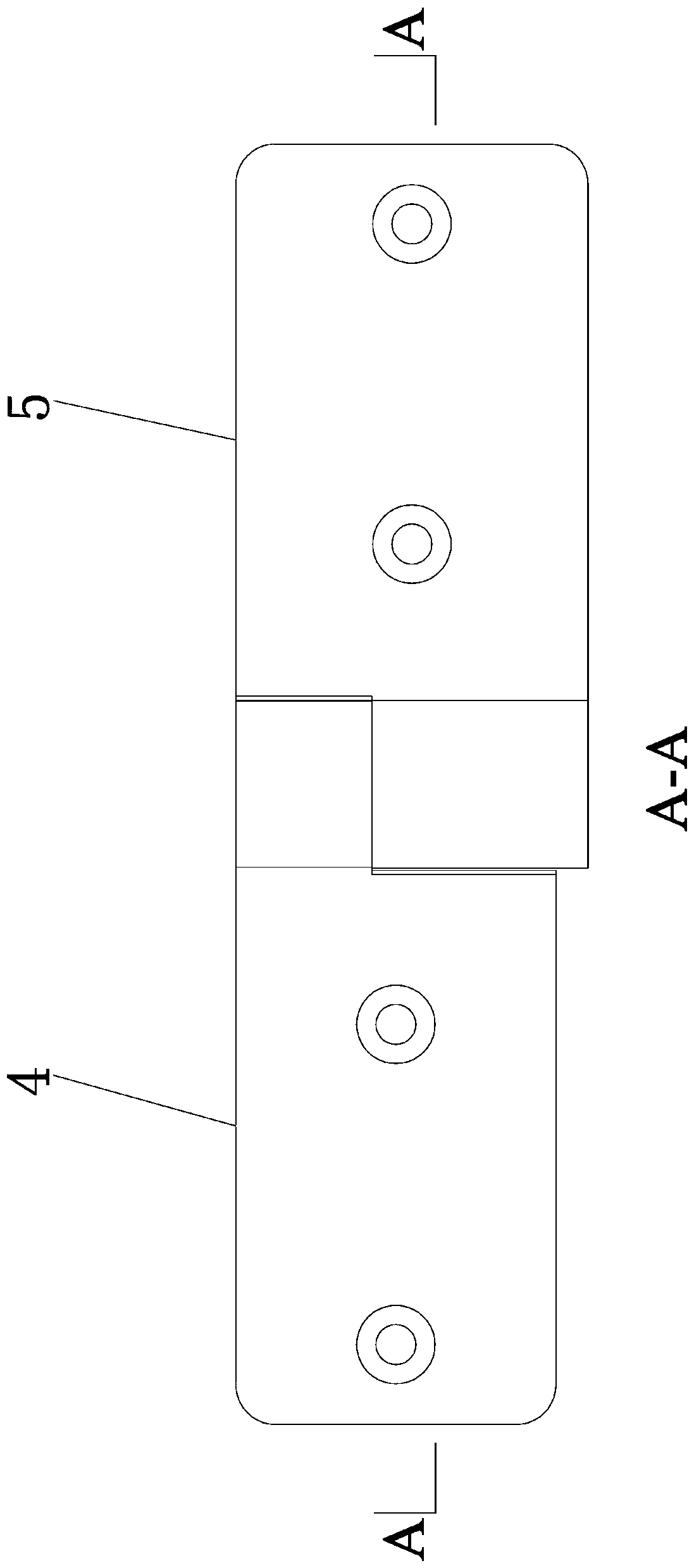

A lifting hinge structure

A technology of hinge structure and hinge piece, which is applied in the direction of hinges with pins, building structures, door/window accessories, etc. It can solve the problems of limited rotation angle of lifting hinges, different lifting hinges, and waterproof failure, so as to reduce the difficulty of processing , to achieve the effect of simple form and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

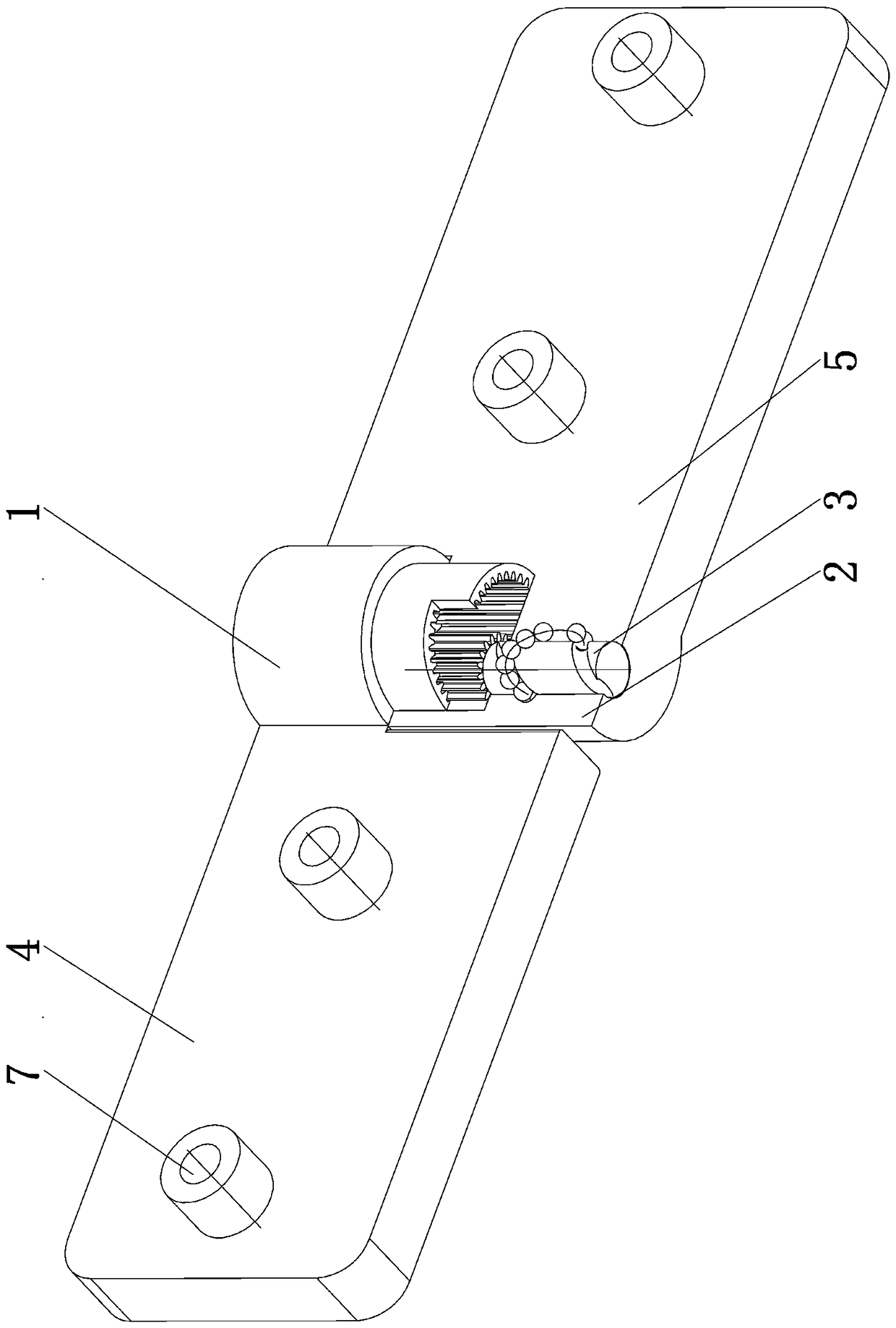

Embodiment 1

[0047] A first helical groove 331 is set on the outer turning surface of the guide post 33, and a first helical groove 331 matching the first helical groove 331 is set on the turning surface in the small hole 212 of the stepped hole 21 on the lower sleeve 2. The protrusion (not shown in the figure), by screwing the first helical protrusion (not shown in the figure) into the first helical groove 331 , the connection of the guide post 33 in the lower sleeve 2 can be realized.

[0048] Specifically, a helical first curved groove 2122 is set on the inner turning surface of the small hole 212 of the stepped hole 21, and the ball 6 is loaded in the first curved groove 2122, so that the ball 6 exposes the small hole in the stepped hole 21. The spiral protrusion formed on the inner wall surface of 212 constitutes the above-mentioned first spiral protrusion (not shown in the figure).

Embodiment 2

[0050] A second helical groove 2121 is set on the inner turning surface of the small hole 212 of the step hole 21 on the lower sleeve 2, and a second helical groove 2121 adapted to the second helical groove 2121 is set on the outer turning surface of the guide post 33. The protrusion (not shown in the figure), by screwing the second helical protrusion (not shown in the figure) into the second helical groove 2121, the connection of the guide post 33 in the lower sleeve 2 can be realized.

[0051] Specifically, a helical second curved groove 332 is set on the outer turning surface of the guide post 33, and the ball 6 is loaded into the second curved groove 332, so that the ball 6 exposes the spiral shape formed by the outer wall surface of the guide post 33. The protrusion constitutes the above-mentioned second spiral protrusion (not shown in the figure).

[0052] During the lifting of the hinge structure, the first hinge piece 4 is driven, so that the first hinge piece 4 drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com