Connection method for prefabricated shear wall-laminated beams in assembled type RC frame-shear structure

A technology of prefabricated shear force and connection method, which is applied in the direction of building structure and construction, can solve the problems of noise pollution, hidden dangers of construction safety, large amount of wet work, etc., and achieve construction cost savings, good seismic performance, and short construction period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

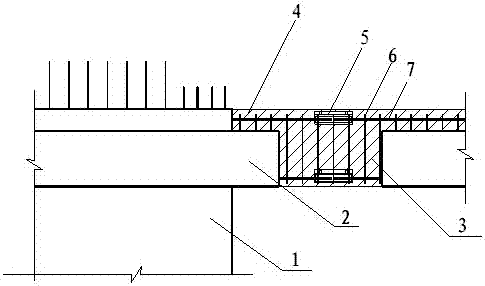

[0017] Such as figure 1 As shown, considering that in the RC frame-shear wall structure, the coupling beam is the bridge connecting the shear wall and the frame, and the stiffness of the shear wall is much larger than that of the frame, the coupling beam actually acts to transfer the seismic force on the wall The bridging effect smoothly transmitted to the frame, the damage of the coupling beam is generally more serious in actual earthquakes. In view of the importance of the coupling beam, in the fully assembled RC frame-shear wall structure;

[0018] The stirrup at the post-casting zone of the composite beam on the outer side of the shear wall needs to be densified to ensure that the shear strength of the beam end is large enough to prevent damage in the earthquake. The connection between the shear wall and the composite beam in the fully assembled RC frame-shear wall structure refers to the connection between the frame column and the composite beam. A wall beam is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com