Polarizing plate packaging device

A technology of polarizing plates and load-carrying bottom plates, which can be used in packaging, transportation and packaging, and packaging of vulnerable items. It can solve problems such as poor sealing performance, and achieve the effects of enhancing sealing performance, avoiding dust pollution, and maintaining cleanliness and relative humidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

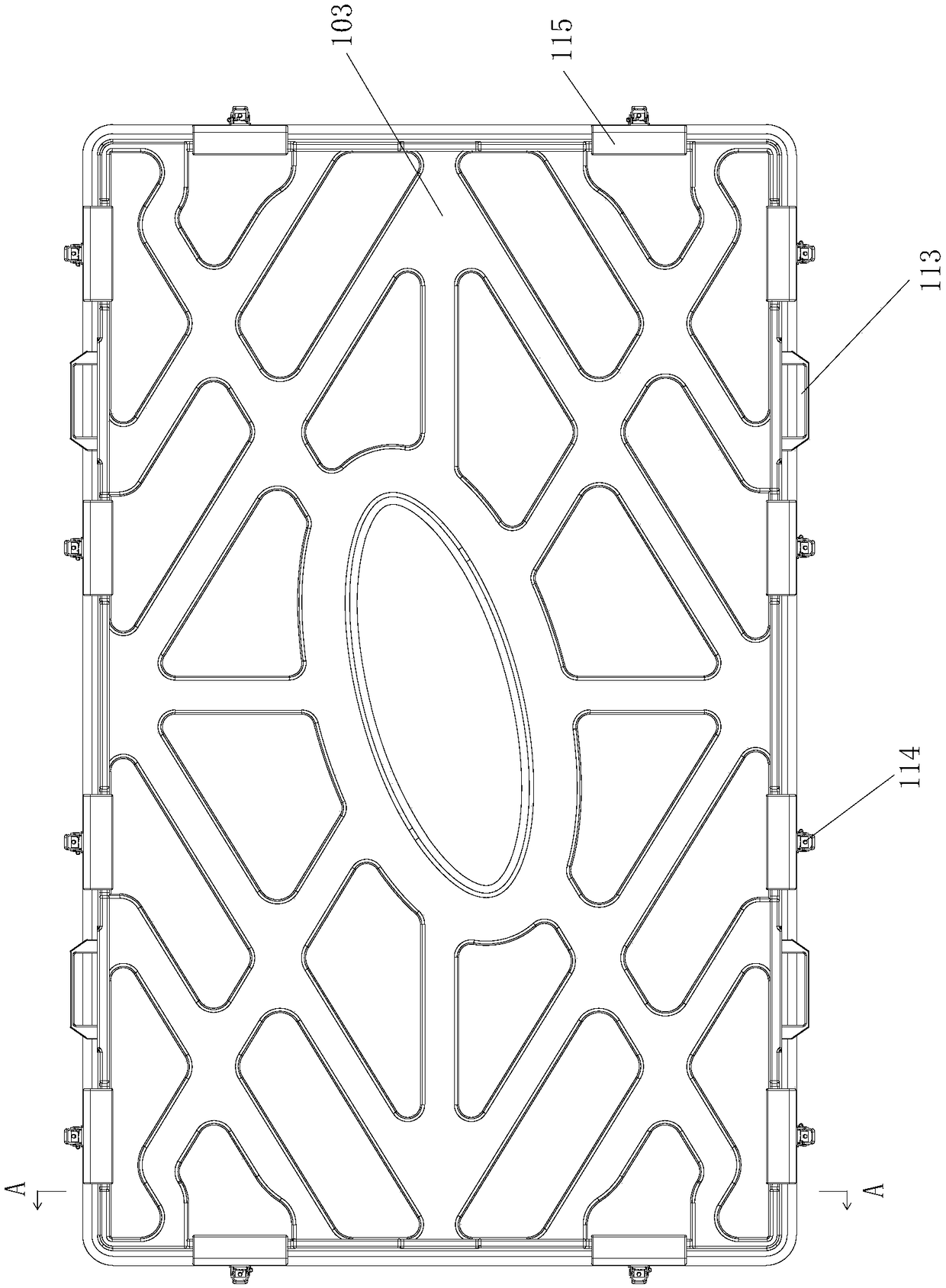

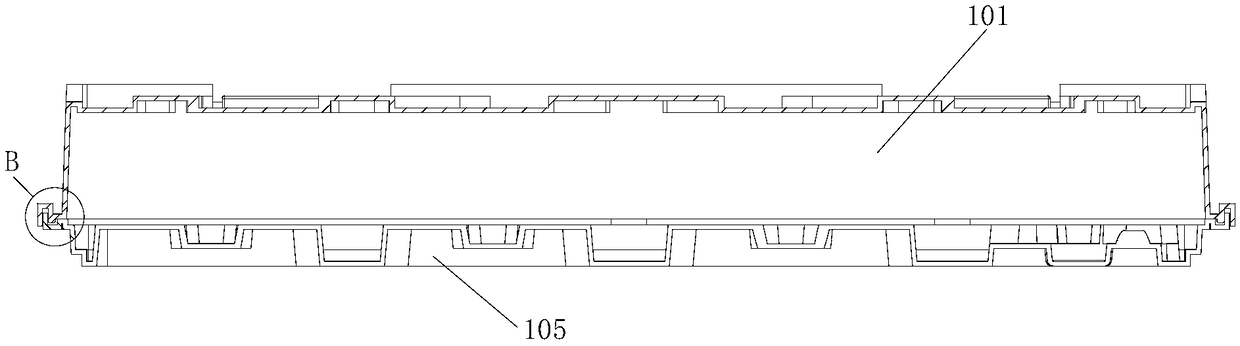

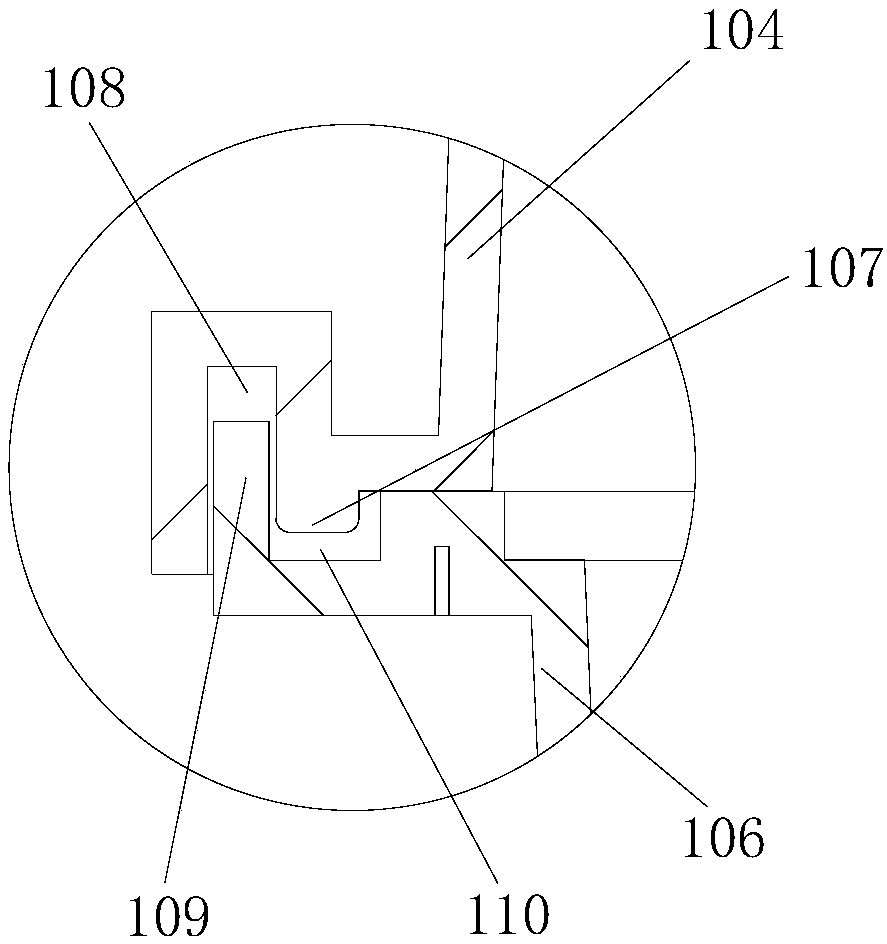

[0035] figure 1 It is a schematic top view structural diagram of the polarizing plate packaging device provided in Embodiment 1 of the present invention; figure 2 for figure 1 A partial sectional view along line A-A of ; image 3 for figure 2 Partial enlarged view of B in middle; Figure 4 A schematic diagram of the uncovered state of the polarizer packaging device provided in Embodiment 1 of the present invention; Figure 5 for Figure 4 Partial enlarged view at C in middle; Image 6 A schematic diagram of the internal structure of the polarizing plate packaging device provided in Embodiment 1 of the present invention; Figure 7 Schematic diagram of the structure of the sliding assembly provided by Embodiment 1 of the present invention; Figure 8 Schematic diagram of the structure of the polarizing plate packaging device provided in Embodiment 1 of the present invention; Figure 9 for Figure 8 Partial enlarged view at E in middle; Figure 10 It is a schematic str...

Embodiment 2

[0062] Figure 11 It is a schematic diagram of the front view structure of the polarizing plate packaging device provided in Embodiment 2 of the present invention; Figure 12 for Figure 10 Partial enlarged view at D in middle. In order to clearly show the misalignment of the first sealing mechanism and the second sealing mechanism, the box cover 101 and the box body 102 are cut away, and hatching is omitted. It should be noted, Figure 11 with Figure 12 The first sealing ring and the second sealing ring are not shown in . see Figure 11 with Figure 12 As shown, this embodiment also provides a polarizing plate packaging device. The polarizing plate packaging device in this embodiment describes another implementation scheme in which the first sealing mechanism and the second sealing mechanism are staggered. The technical solution of Embodiment 1 also belongs to this embodiment, and will not be described again here. The same components use the same reference numerals a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com