Disassembly and assembly device special for piston and connecting rod unit of automobile engine and using method

An automobile engine, piston connecting rod technology, applied in hand-held tools, manufacturing tools and other directions, can solve the problems of difficulty in taking out the piston and connecting rod group, low disassembly and assembly efficiency, and narrow position, and achieves good promotion and application value. The effect of reducing maintenance time and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

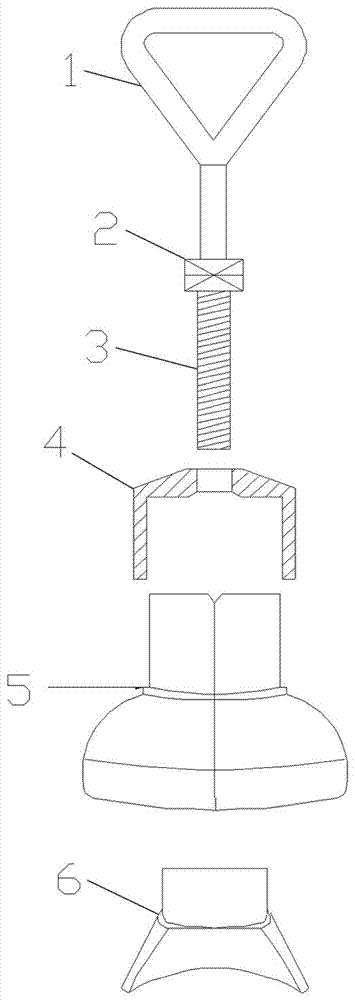

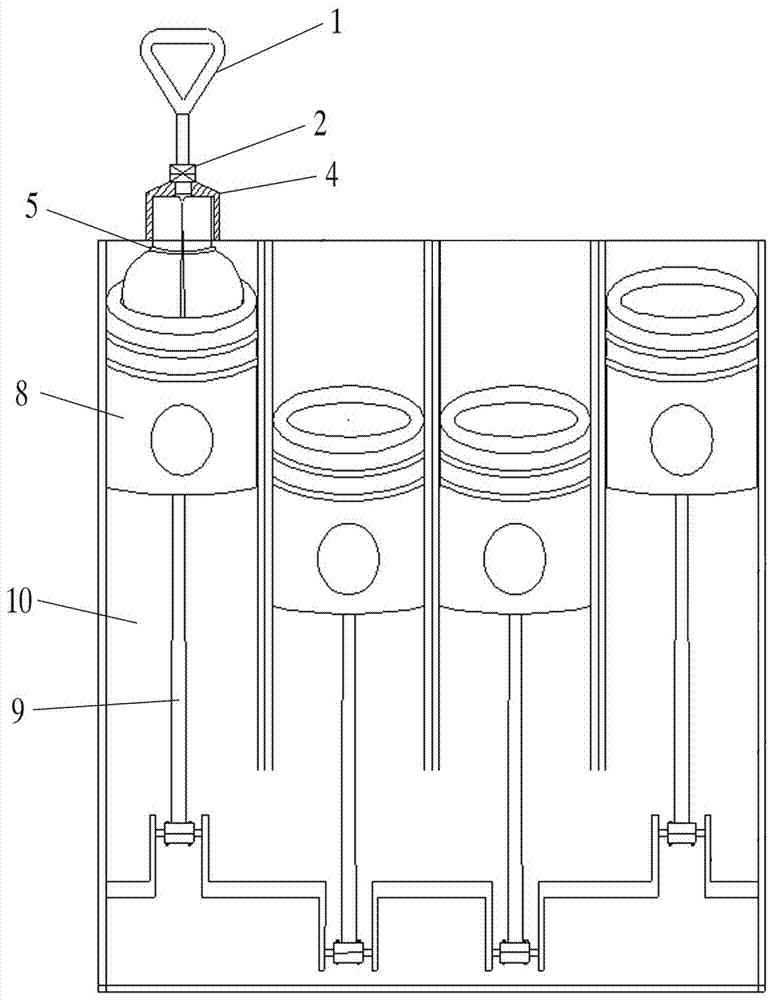

[0024] see Figure 1-Figure 3 , a special disassembly and assembly device for the piston connecting rod group of an automobile engine, which consists of a pull ring 1, a screw rod 2, a fastening bolt 3, a cage 4, a left and right movable wedge 5 and a fastening wedge 6, which are sequentially connected from top to bottom. According to the structure of the piston 8 and the size of the combustion chamber 10, the left and right movable wedges 5 of different diameters are selected and placed in the groove 7 on the top of the piston 8, and after they are tightened, the 9 groups of connecting rods of the piston 8 are pulled out or installed into the engine.

[0025] The hole diameter of the pull ring 1 is 60mm.

[0026] The size of the screw 2 is ¢10mm*40mm.

[0027] The size of the fastening bolt 3 is ¢10mm*50mm.

[0028] The cage 4 has an outer diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com