Disassembling spanner for outer hexagon bolt

A technology of external hexagon and bolts, which is applied in the field of wrenches, can solve the problem of unfixed wrench and bolts, and achieve the effects of simple structure, faster fastening speed and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

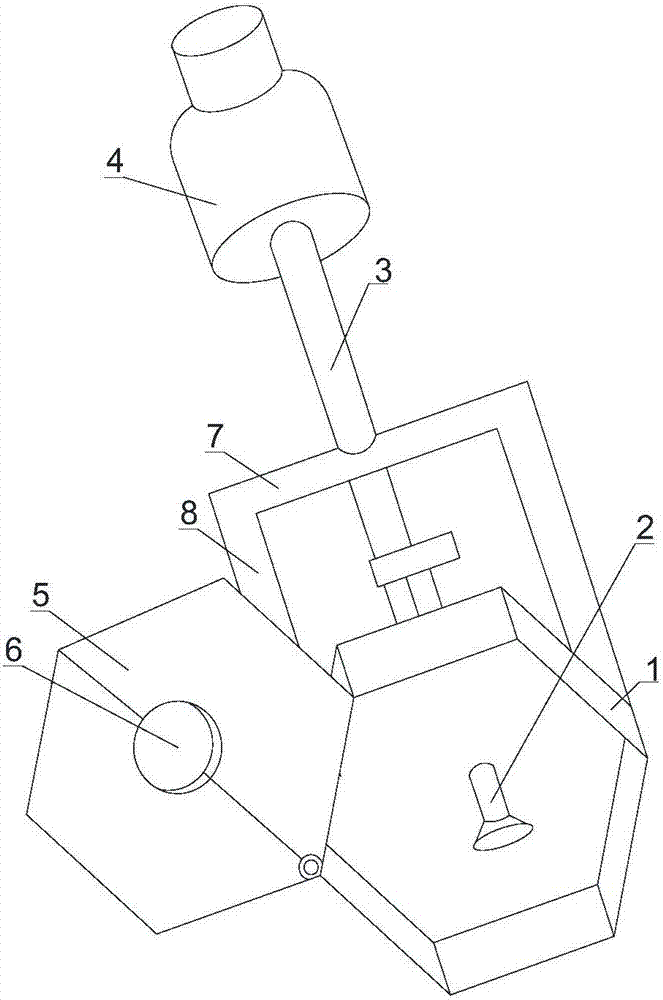

[0022] Such as figure 1 As shown, the dismounting wrench of the outer hexagonal bolt of the present invention includes a clamping part 1 for fixing the bolt, and the bottom of the clamping part 1 is provided with an opening for the outer hexagonal bolt nut to enter the inside of the clamping part 1, and the clamping part 1 A vacuum chuck 2 is arranged inside, and the suction rod of the vacuum chuck 2 is located above the clamping part 1, and a rotating rod 3 is also connected above the clamping part 1, and the rotating rod 3 is controlled by a motor 4 installed at one end of the rotating rod 3 When it rotates, a lower cover 5 is connected below the clamping part 1, and the lower cover 5 is hinged to a bottom edge of the clamping part 1, and the center of the lower cover 5 is provided with a through hole for the outer hexagonal bolt screw to pass through. 6. The lower cover 5 is composed of a cover plate A and a cover plate B hinged to the cover plate A, and both the cover plat...

Embodiment 2

[0025] Based on Embodiment 1, a hand-held handle is also connected above the clamping portion 1, and the hand-held handle includes a cross bar 7, and both ends of the cross bar 7 are connected with vertical rods 8, and the vertical rod 8 rotates with the clamping portion 1. Connected, the rotating rod 3 passes through the cross bar 7 and is connected with the clamping part 1 . The hand-held handle is used to fix and support the clamping part, the cross bar is for the user to hold, and the vertical bars at both ends of the cross bar are convenient for the user to adjust the position of the clamping part, and the force distribution of the user acting on the clamping part is more uniform. The hand-held handle in the present invention is a simple and practical support device for the support clip device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com