Riveting device for pressing disk in cover assembly

A pressure plate and riveting technology, which is applied in the assembly field of the clutch cover assembly, can solve problems such as product and positioning looseness or tightness, troublesome production, lower production efficiency and product quality, so as to improve work efficiency, avoid positioning deviation, The effect of avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

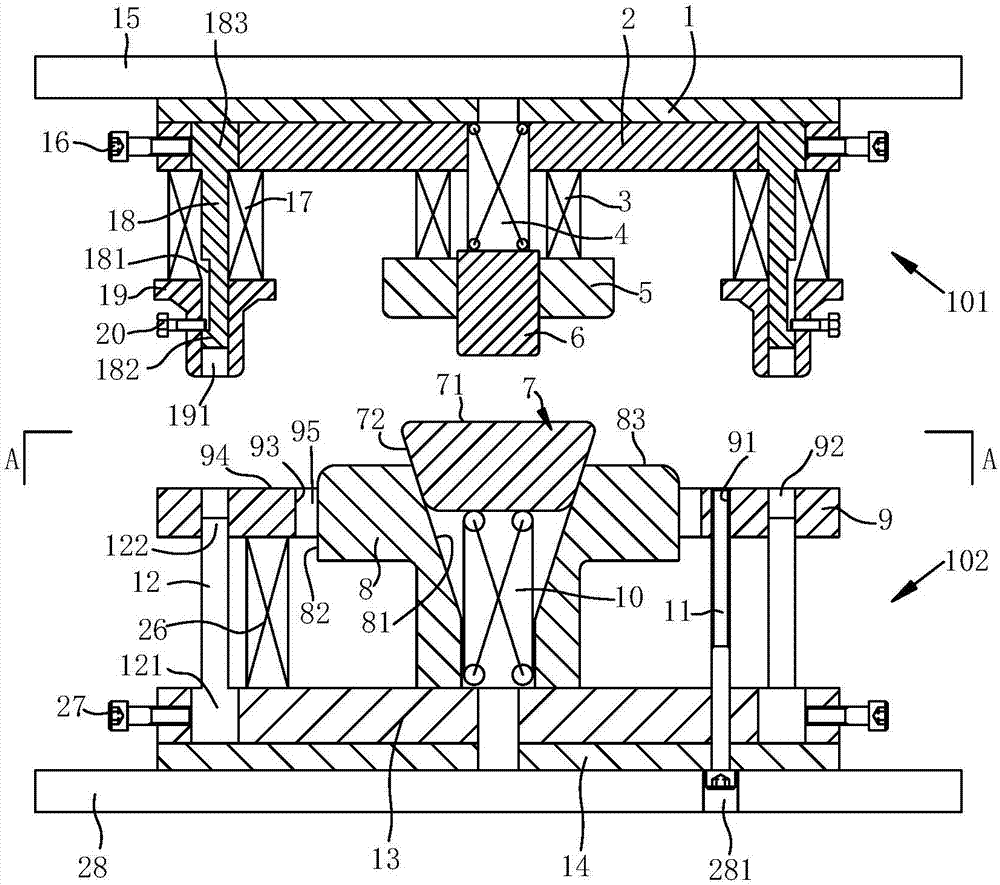

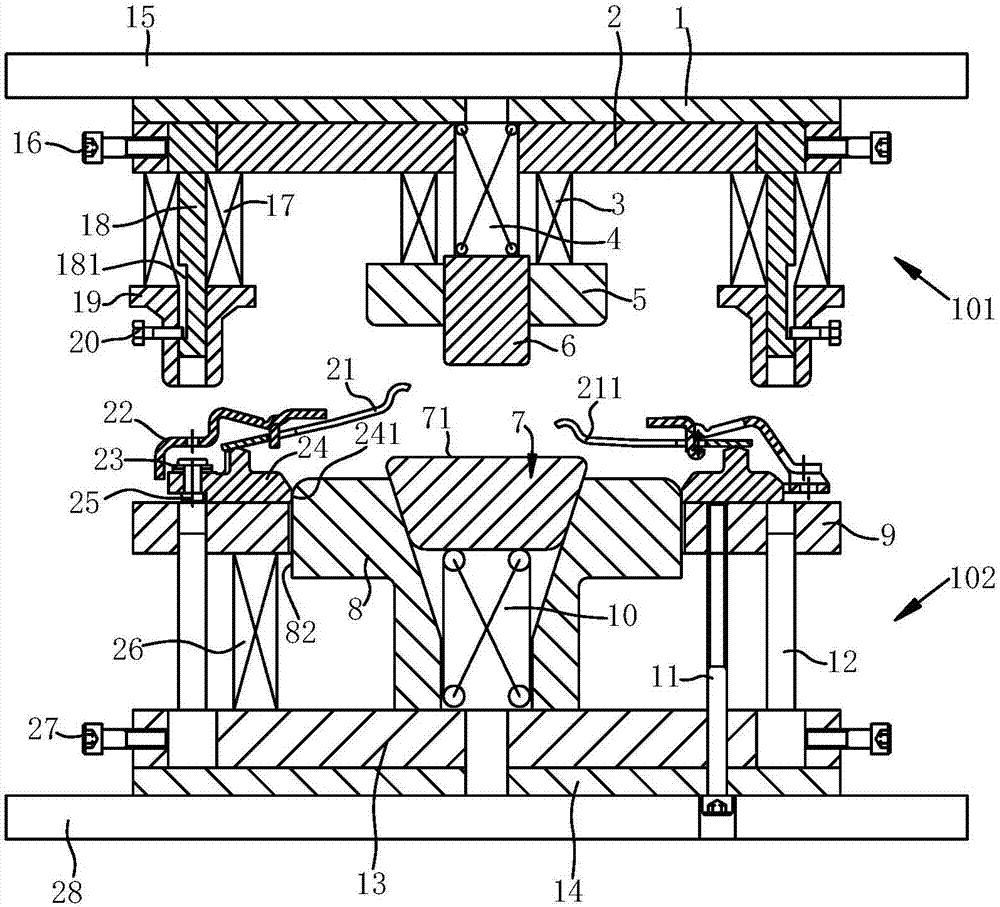

[0028] refer to figure 1 and figure 2 , a riveting device for the pressure plate in the cover assembly, the upper cover plate 15 and the lower cover plate 28 are arranged up and down, and the upper riveting device 101 fixed on the upper cover plate is arranged on the lower side of the upper cover plate. The upper side of the plate is provided with a lower riveting device 102 .

[0029] The upper riveting device 101 and the lower riveting device 102 correspond up and down, and the upper riveting device includes a horizontally arranged upper fixing plate 2 and a positioning assembly and an upper riveting assembly installed on the lower side of the upper fixing plate. The upper fixing plate 2 is fixed on the lower side of the upper cover plate 15, and an upper rubber pad 1 is placed between the upper fixing plate and the upper cover plate.

[0030] The positioning assembly includes a first elastic piece 4 and a second elastic piece 3 fixedly arranged on the upper fixing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com