Hydraulic drive efficient correction leveling assembly for silicon steel column

A silicon steel and leveling technology, applied in the field of silicon steel column processing devices, can solve the problems of affecting the correction effect, correction failure, and unstable deformation position of the silicon steel column, so as to achieve the effect of improving the accuracy of the effect, reducing the correction error, and adapting the position setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

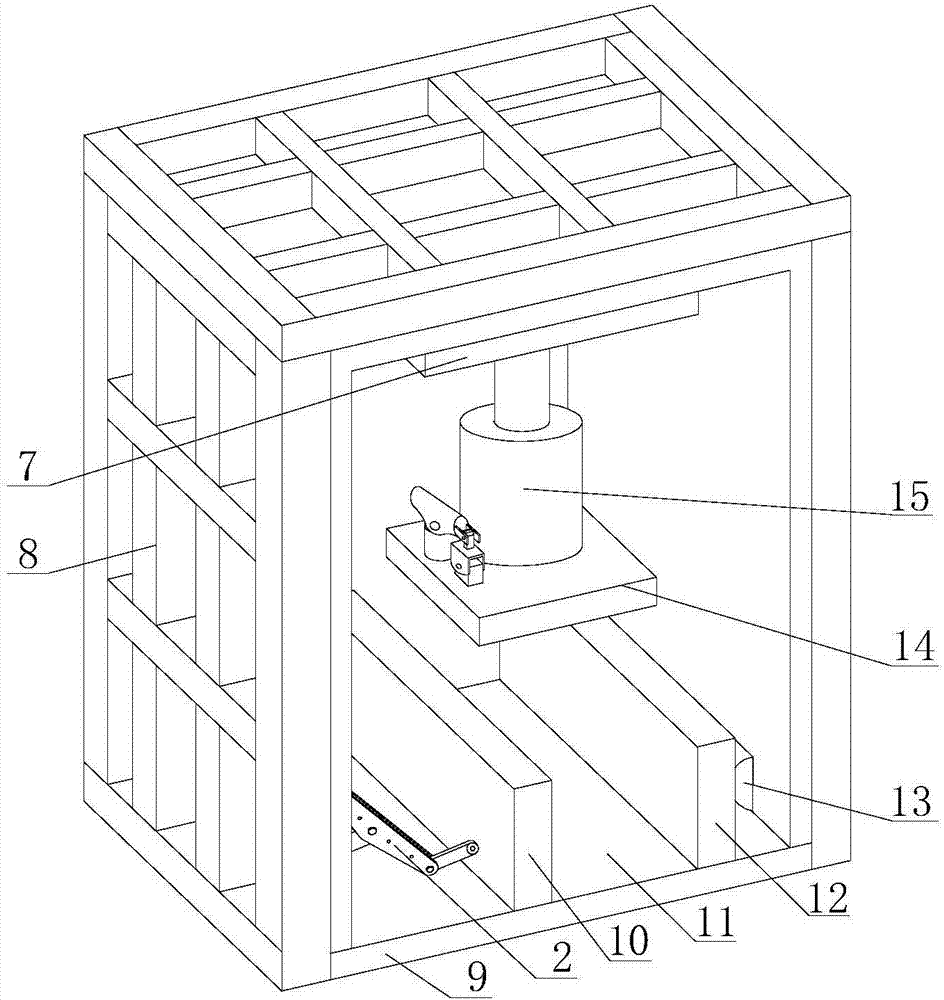

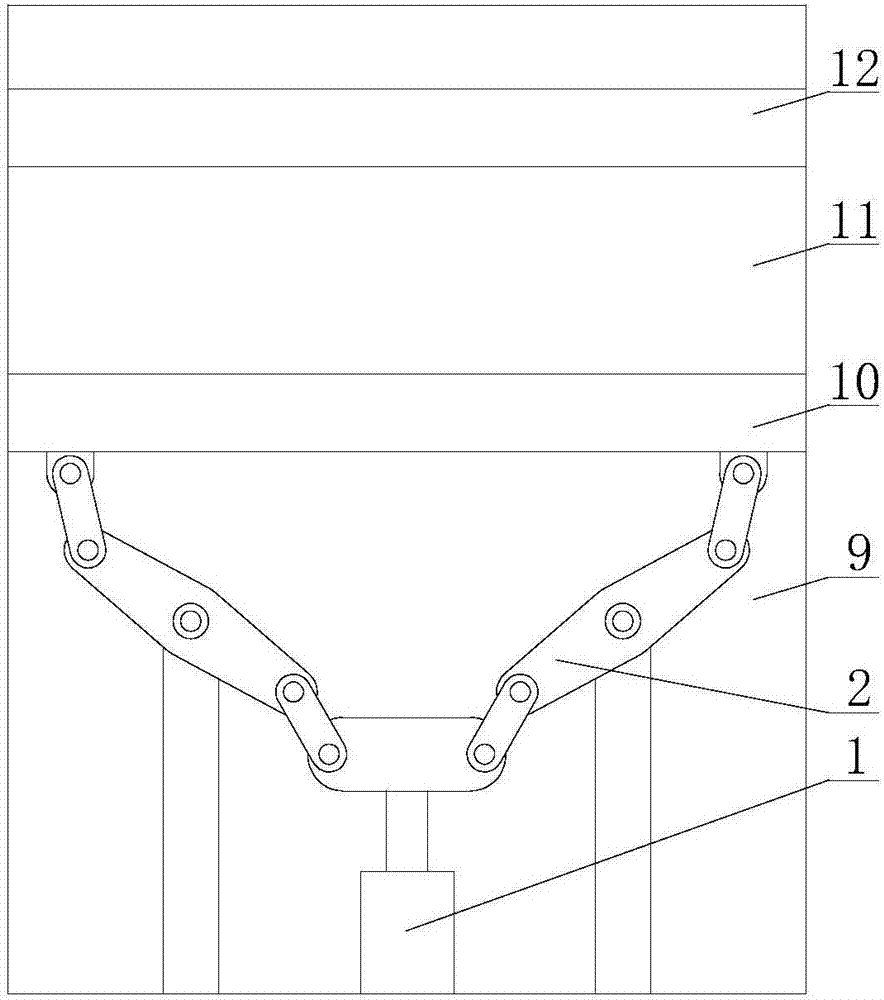

[0034] A silicon steel column hydraulic high-efficiency correction and leveling assembly, which includes a square frame 9 composed of four metal plates, the front and rear sides of the square frame 9 are open. A vertical correction device and a horizontal correction device are arranged in the square frame body 9. The vertical correction device can correct and level the silicon steel column from the vertical direction, and the horizontal correction device can correct and level the silicon steel column from the horizontal direction. And when in use, the horizontal correction device and the vertical correction device cooperate to correct and level the silicon steel column from both horizontal and vertical directions. The first clamping plate 12 and the second clamping plate 10 oppositely arranged on the inner bottom surface of the square frame body 9, the second clamping plate 10 can slide horizontally relative to the first clamping plate 12, and an adjustable spacing is formed be...

Embodiment 2

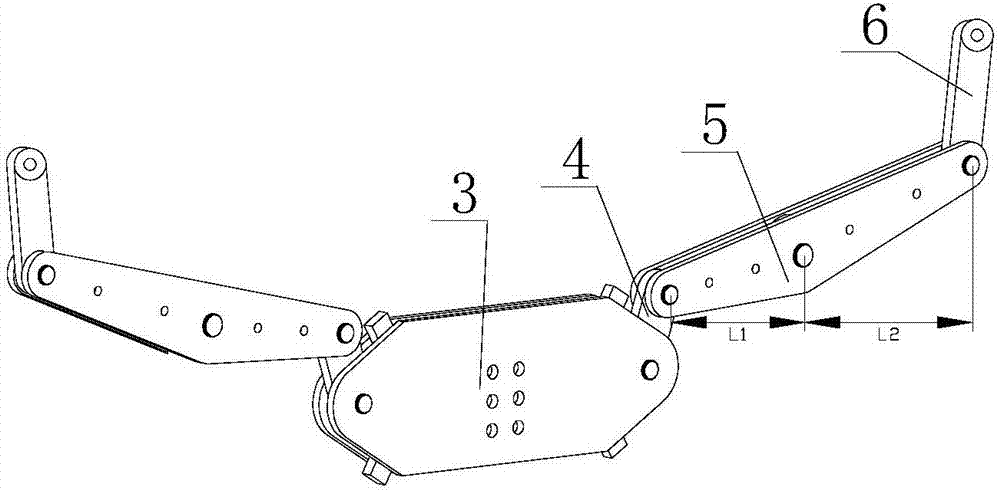

[0036] On the basis of the first embodiment, the pushing mechanism 2 includes a translation block 3 which is directly connected to the drive shaft of the hydraulic cylinder 1 and slides under the action of the hydraulic cylinder 1 . Both ends of the translation block 3 are hinged with first cranks 4 , and the ends of the other ends of each set of first cranks 4 are hinged with rotating rods 5 . The middle part of the rotating rod 5 is hinged with the square frame body 9 so that the rotating rod 5 can rotate in the square frame body 9 . The other end of the rotating rod 5 is hinged with a second crank 6 , and the other end of the second crank 6 is hinged with the first splint 12 or the second splint 10 . Two sets of first cranks 4 , rotating rods 5 and second cranks 6 are symmetrically arranged on the left and right sides of the translation block 3 . When the hydraulic cylinder 1 operates, it will drive the translation block 3 to move, and the movement of the translation block...

Embodiment 3

[0038] Based on the second embodiment, on the rotating rod 5 , the length of the first moment arm L1 of the rotating rod 5 is smaller than the length of the second moment arm L2 of the rotating rod 5 . The length of the first moment arm L1 refers to the distance between the two hinge points between the hinge point where the swing rod 5 and the first crank 4 are hinged and the hinge point where the swing rod 5 and the square frame 9 are hinged on the swing rod 5; The length of the second moment arm L2 refers to the distance between the hinge point on the rotating rod 5 where the rotating rod 5 and the second crank 6 are hinged and the hinge point where the rotating rod 5 and the square frame 9 are hinged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com