Picking and conveying integrated mechanism

An integrated, shell technology, applied in the direction of solid separation, separation of solids from solids with airflow, chemical instruments and methods, etc., can solve the problems of working environment pollution, large investment in equipment, raising dust, etc., and achieve reduction Pollution, Efficiency Improvement, Significant Technical Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

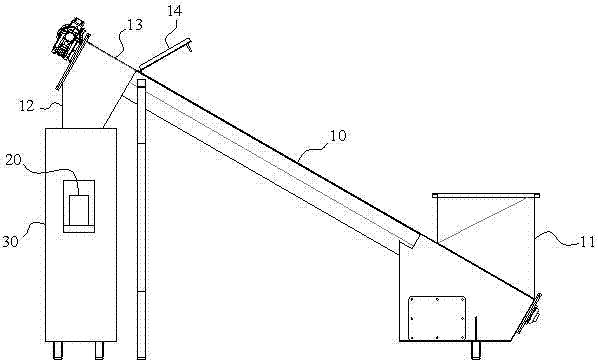

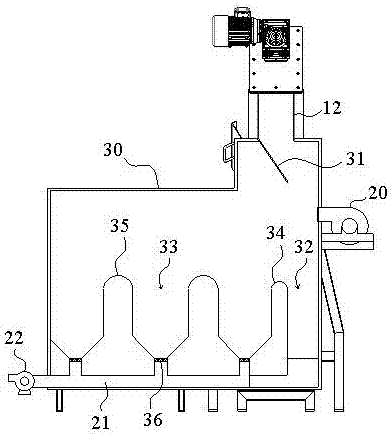

[0013] like figure 1 , figure 2 As shown, the present invention provides an integrated mechanism for picking and conveying materials, including a housing 10, the two ends of the housing 10 are respectively connected with a material inlet 11 and a material outlet 12, and a winnowing device is arranged below the material outlet 12. Storehouse 30, wind selection storehouse 30 side is provided with air blower 20 near the position below discharge port 12, and below discharge port 12 is provided with deflector 31 pointing to air blower 20 tuyere, air selection storehouse 30 inside according to the horizontal distance with blower 20 From near to far, it comprises a hard impurity bin and a seed screening bin. The bottom of the seed screening bin communicates with the exhaust duct 21, and the exhaust duct 21 is connected with the exhaust fan 22 on the outside of the winnowing bin 30. In this technical scheme, air blower 20 is arranged in air separation bin 30, and the grain seeds fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com