Gravel separator adopting step-by-step centrifugation

A centrifugal separation, sand and gravel separation technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of incomplete separation, poor separation effect, low efficiency, etc., to improve work efficiency and quality. , cost saving, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

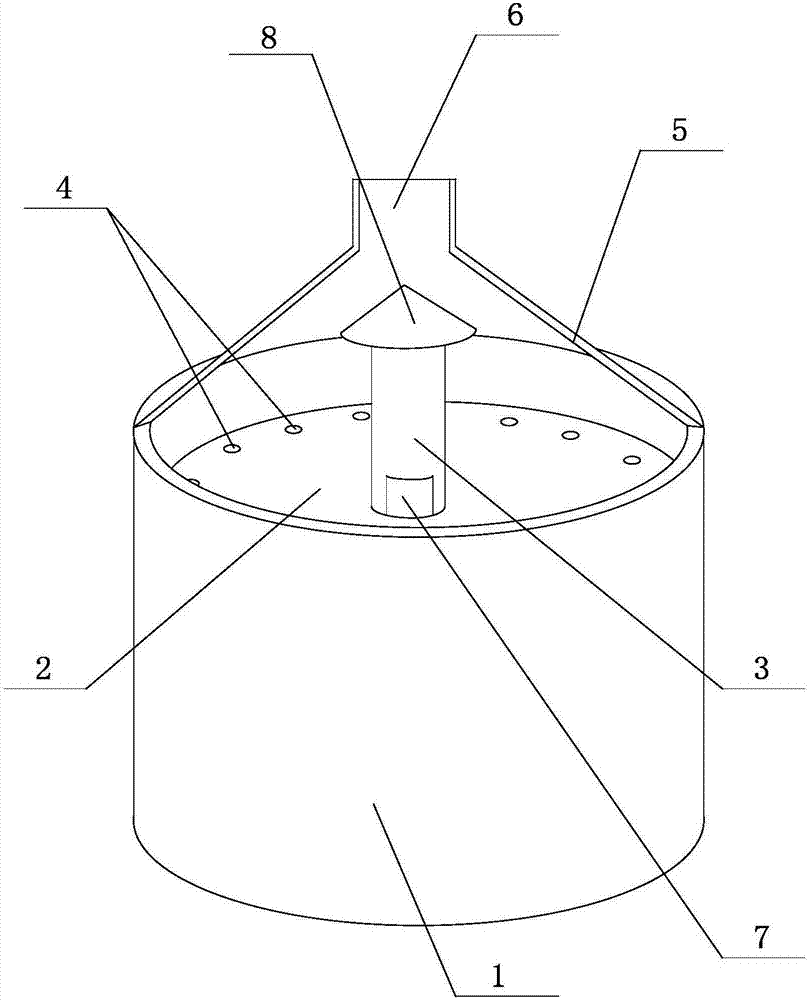

[0021] like figure 1 As shown, the present invention adopts a step-by-step centrifugal sand-stone separator, including a cylindrical separator body 1, and a plurality of centrifugal separation plates 2 are arranged in sequence from top to bottom in the separator body 1, and the center of the centrifugal separation plate 2 There is a rotating shaft 3 that runs through a plurality of centrifugal separation plates 2, and the rotating shaft 3 drives the centrifugal separation plates 2 to rotate in the horizontal direction; on the centrifugal separation plate 2, a plurality of separation holes 4 are provided on the outer ring far away from the rotating shaft 3, The size of the separation holes on the plurality of centrifugal separation plates 2 from top to bottom decreases successively; a protective cover 5 is provided on the upper side of the separator body 1 , and a feed port 6 is provided above the protective cover.

[0022] The sand and gravel separator of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com