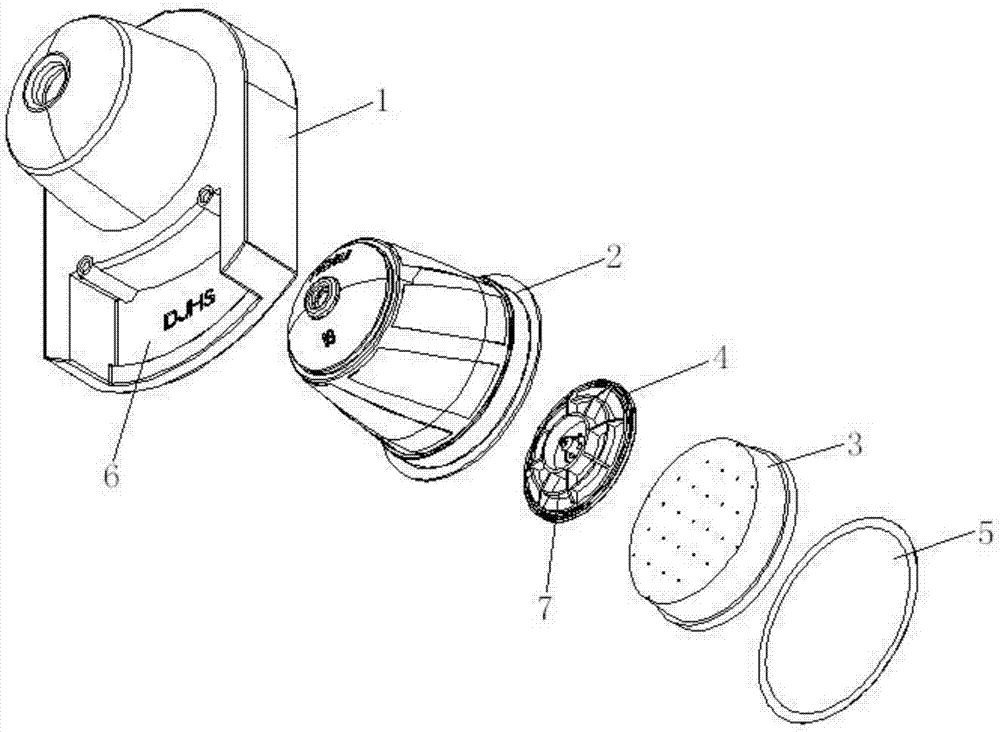

Beverage ingredient container achieving stable-pressure outputting

A technology for beverage ingredients and stabilized output, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as pollution, reduced beverage taste, and easy splashing of beverages out of the cup, so as to prolong the dissolution time, improve the taste, and avoid problems. The effect of wasted beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

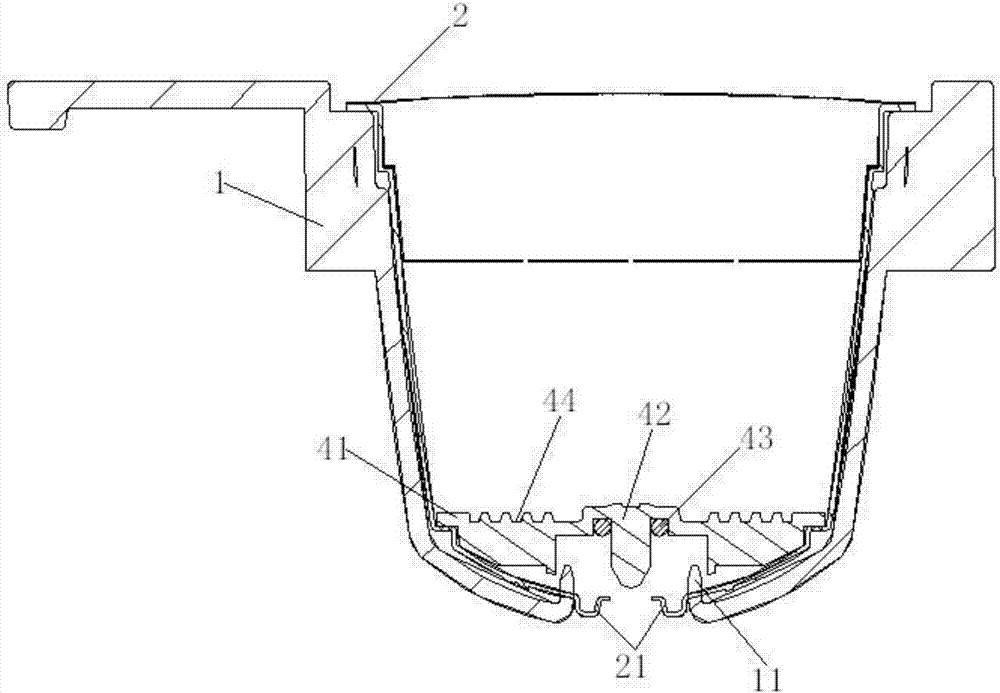

[0029] like figure 2 As shown, the micro-filter reverse pressure device 4 includes a filter disc 41, the surface of the filter disc 41 is provided with a diversion groove 44, the middle bottom of the filter disc 41 is provided with a shaft post 42, and the filter disc 41 is surrounded by a shaft post 42. As for the pores, a rubber ring 43 is sheathed on the surface of the shaft column 42 , and the rubber ring 43 is used to close the pores around the shaft column 42 . The diversion groove 44 is centered on the shaft column 42, and is annularly arranged on the surface of the filter disc 41. The diversion groove 44 includes a multi-layer structure, and the middle part of the diversion groove 44 is also provided with a water flow groove. This layer-by-layer diversion structure, in The vortex is caused by the washing of water pressure, thus accelerating the dissolution of powder.

[0030] In this embodiment, the hole is set on the top of the filter plate 41, and the rubber ring 4...

Embodiment 2

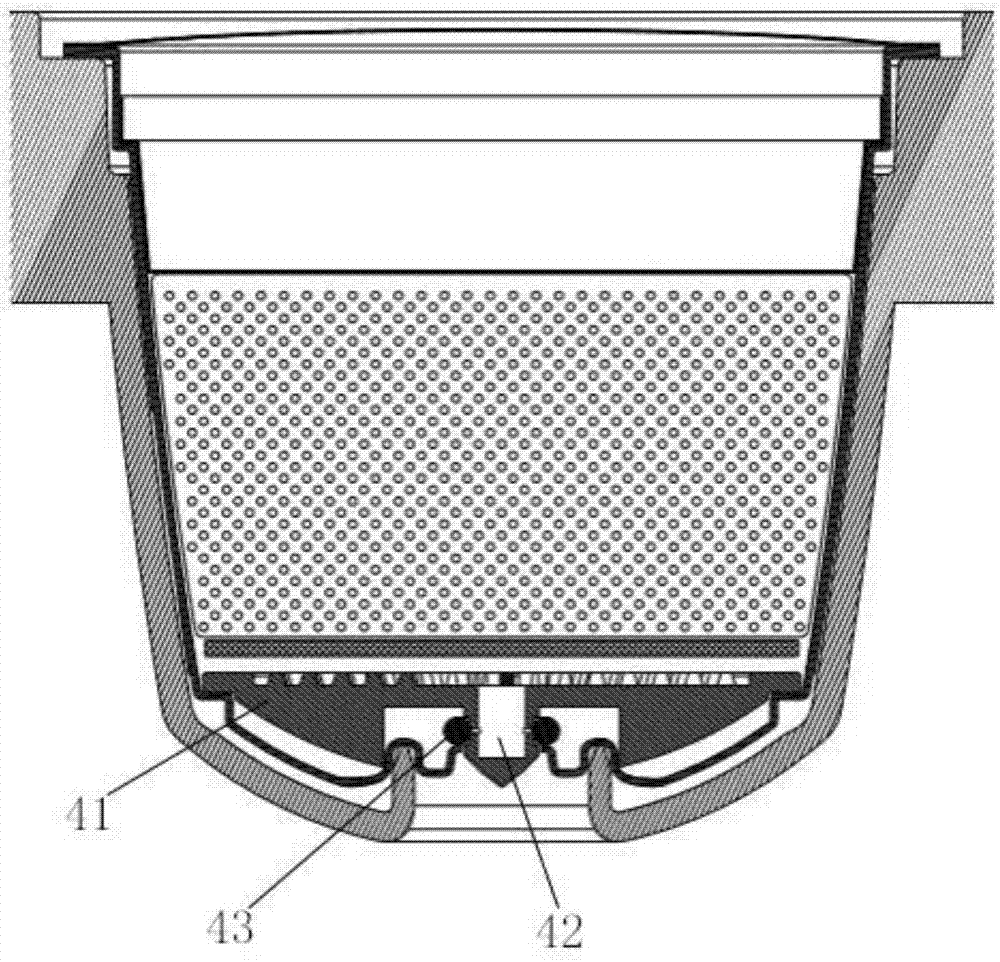

[0038] like image 3 As shown, the micro-filter reverse pressure device 4 includes a filter disc 41, the surface of the filter disc 41 is provided with a guide groove 44, the middle bottom of the filter disc 41 is provided with a shaft column 42, and a rubber ring 43 is sleeved on the surface of the shaft column 42, The rubber ring 43 is used to close the pores around the shaft column 42 . The diversion groove 44 is centered on the shaft column 42, and is annularly arranged on the surface of the filter disc 41. The diversion groove 44 includes a multi-layer structure, and the middle part of the diversion groove 44 is also provided with a water flow groove. This layer-by-layer diversion structure, in The vortex is caused by the washing of water pressure, thus accelerating the dissolution of powder.

[0039] In this embodiment, the pores are opened on both sides of the shaft column 42, and the rubber ring 43 is sleeved on the outer surface of the hole. The shaft column adopts a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com