Complex probiotic fermented feed and manufacturing process thereof

A technology for compound probiotics and fermented feed, which is applied in the field of compound probiotic fermented feed and its manufacturing process, can solve the problems of shortage of raw materials, high cost, influence on the reproduction of lactic acid bacteria, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

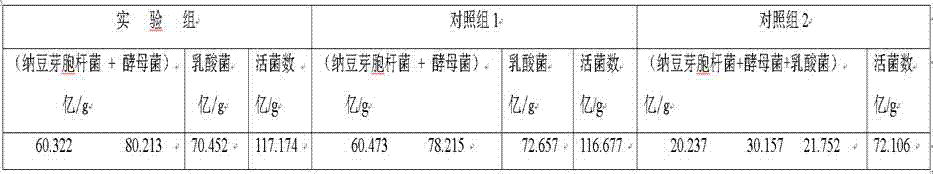

Examples

Embodiment Construction

[0032] The first embodiment:

[0033] 1. Selection of fermentation raw materials:

[0034] By weight, 0.5-1.0 parts of Bacillus natto, 0.7-1.2 parts of lactic acid bacteria, 0.3-0.8 parts of yeast, and 30-60 parts of fermentation substrate are taken. Among them, the fermentation substrate is rice bran, alcohol residue, rapeseed meal, alfalfa meal, corn meal, and medical stone powder, and the weight ratio is rice bran: alcohol residue: rapeseed meal: alfalfa meal: corn meal: Maifan stone powder = 12-15: 2-3: 4-5: 7-10: 1-3: 0.01-0.03.

[0035] Rice bran is made up of rice bran and rice husk powder = 1:2. A large number of experiments have proved that the physical and chemical characteristics of rice bran are very suitable for the growth of various microorganisms, especially for the growth of Bacillus natto.

[0036] Alfalfa, formerly known as lentils, alfalfa, wild alfalfa, clover, and horn flower, has more protein than soybeans, but its cost is much lower than soybeans, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com