The method of extracting the dynamic vibration frequency

A vibration frequency, dynamic technology, applied in the measurement of vibration, vibration measurement in solids, instruments, etc., can solve the problem of not revealing the design method of multiple vibration measurement components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

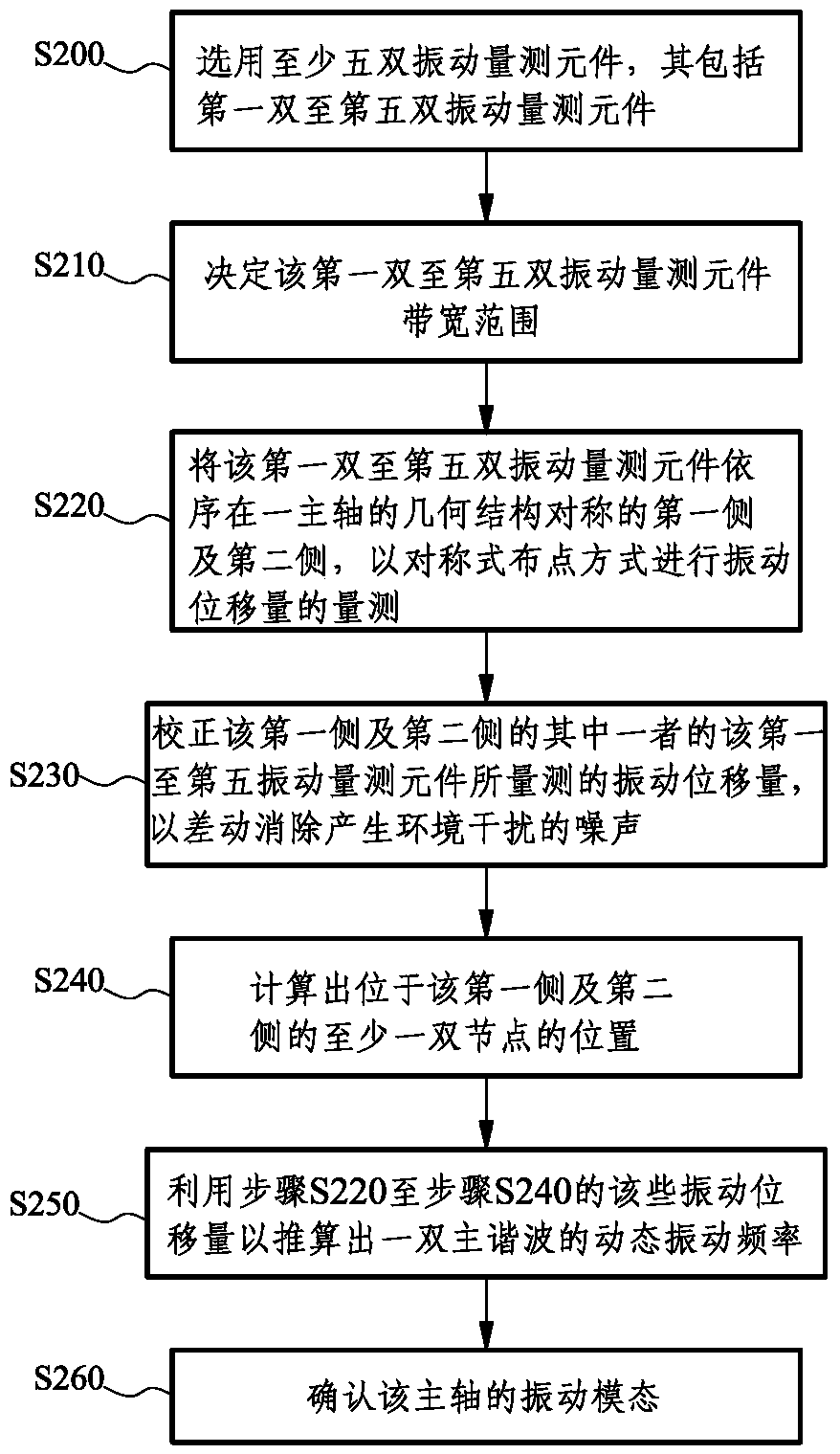

[0027] Please refer to figure 1 , which shows a method for capturing a dynamic vibration frequency according to an embodiment of the present invention, including the following steps:

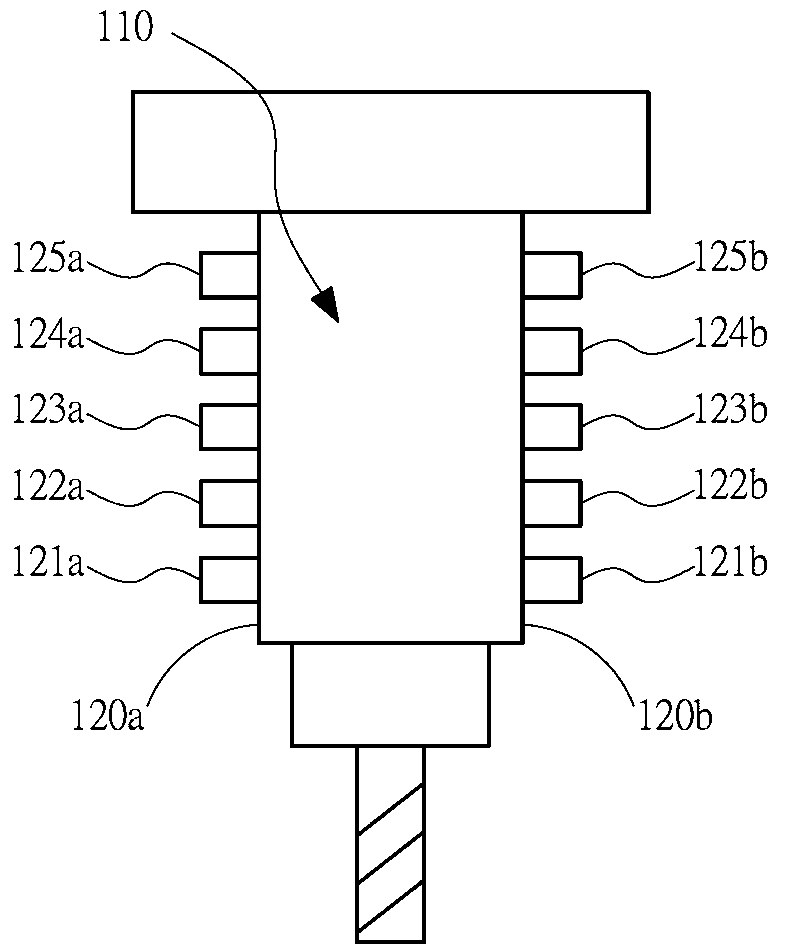

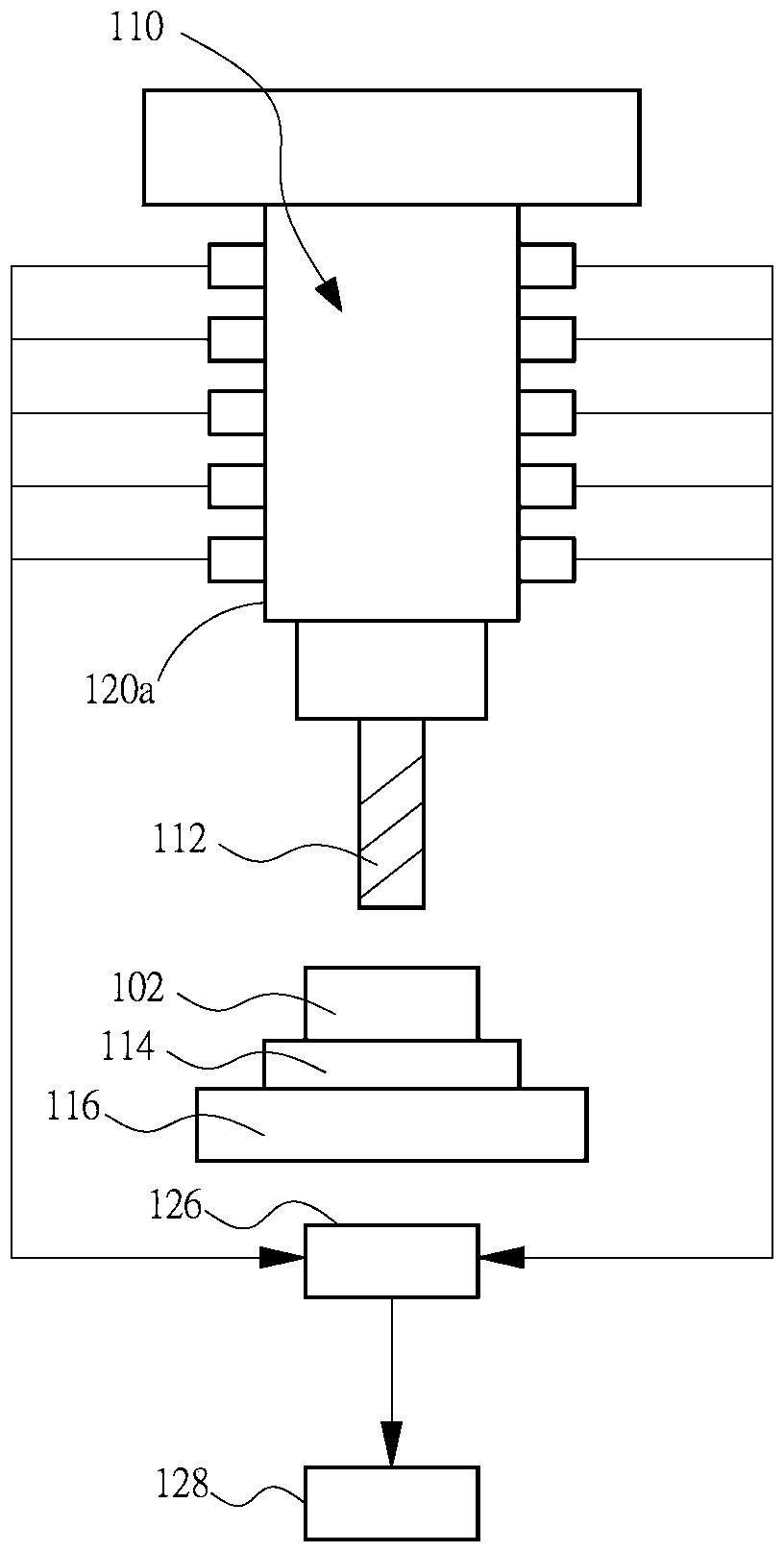

[0028] In step S200, at least five pairs of vibration measuring elements are selected, including first to fifth pairs of vibration measuring elements. Please refer to Figure 2a , which shows the first to fifth dual vibration measuring elements according to an embodiment of the present invention. The first dual vibration measuring elements 121a, 121b include two first vibration measuring elements 121a, 121b, the second dual vibration measuring elements 122a, 122b include two second vibration measuring elements 122a, 122b, and accordingly By analogy, the vibration measuring element can be a vibration accelerometer for measuring a vibration displacement. Please refer to Figure 2a and Figure 2b , a measuring system comprising the first pair to the fifth pair of vibration measuring elements, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com