Processing and making method for Xinyang yellow bud tea

A production method and a technology for yellow bud tea, which are applied in the field of processing and production of Xinyang yellow bud tea, can solve the problems of dark green appearance, weak taste, dullness and the like of yellow tea, and achieve a strong and mellow tea aroma, significant economic benefits, and yellow soup. bright and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

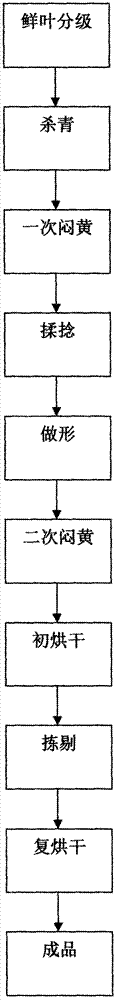

[0023] Attached below figure 1 The preferred embodiments of the present invention are described in detail, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0024] refer to figure 1 , Xinyang yellow bud tea, using the fresh leaves of tea trees suitable for making Xinyang yellow bud tea as raw materials, after fresh leaf grading, greening, first vexation, rolling, shaping, second vexation, initial drying, sorting, re-drying in steps The finished product is made; the tea tree varieties of the Xinyang yellow bud tea made are Fuding Dabai tea, Xinyang group species, Baihaozao, Fuyun No. 6, Bixiangzao, Wuniuzao, Pingyang Tezao, and Xinyang No. 10 tea. one or several. Its specific production method is as follows:

[0025] (1) Grading of fresh leaves: The fresh leaves of the tea tree species suitable for making Xinyang Maojian in Xinya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com