Method for manufacturing solar power generation assembly

A technology for power generation components and manufacturing methods, applied in photovoltaic power generation, electrical components, final product manufacturing, etc., can solve the problems of low light utilization efficiency and difficult to lock light, and achieve the effect of simple preparation process method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

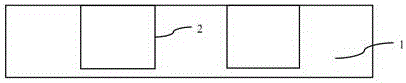

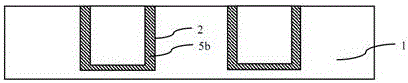

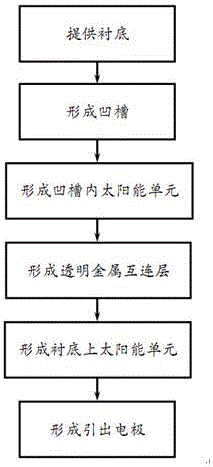

[0024] See figure 1 , The solar power generation component of the present invention includes:

[0025] The silicon substrate 1 has a first surface (upper surface) and a second surface (lower surface) opposite to each other;

[0026] A plurality of grooves 2 formed in the silicon substrate 1;

[0027] A plurality of first solar cell units 4 are accommodated in the plurality of grooves 2, and the top surface thereof is flush with the first surface;

[0028] A plurality of second solar battery units 3 are arranged on the first surface and are arranged in a transversely staggered manner with the plurality of first solar battery units 4;

[0029] The separated first transparent conductive layer 6 is arranged on the first surface and is respectively connected with the top electrode of a first solar battery unit 4 and the bottom electrode of a second solar battery unit 3 to form a plurality of first solar battery groups ;

[0030] The first reflective material layer 5b is formed on the side wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com