Fixing device of glasses lens

A technology for fixing devices and glasses lenses, applied in the field of glasses, can solve the problems of inconvenient use for consumers, inconsistent production standards, and immature assembly process, etc., and achieve the effects of good practicability, easy uniform production standards, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

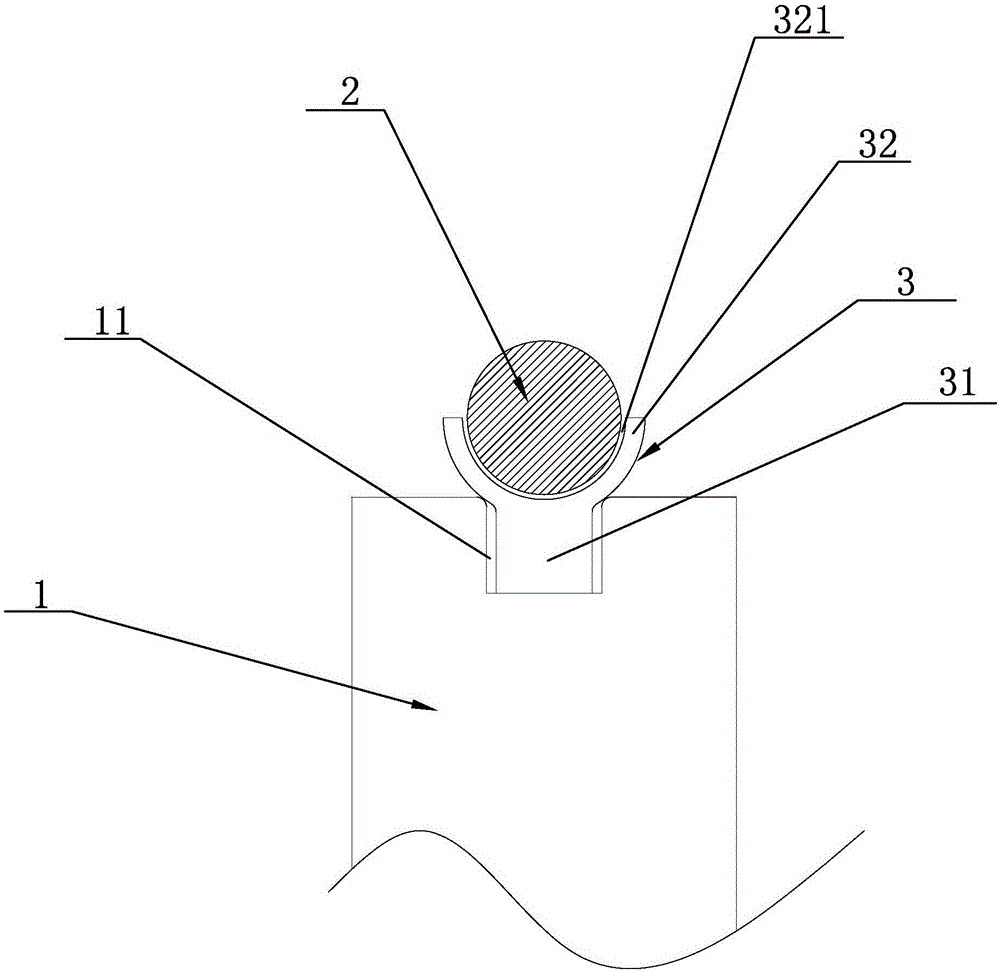

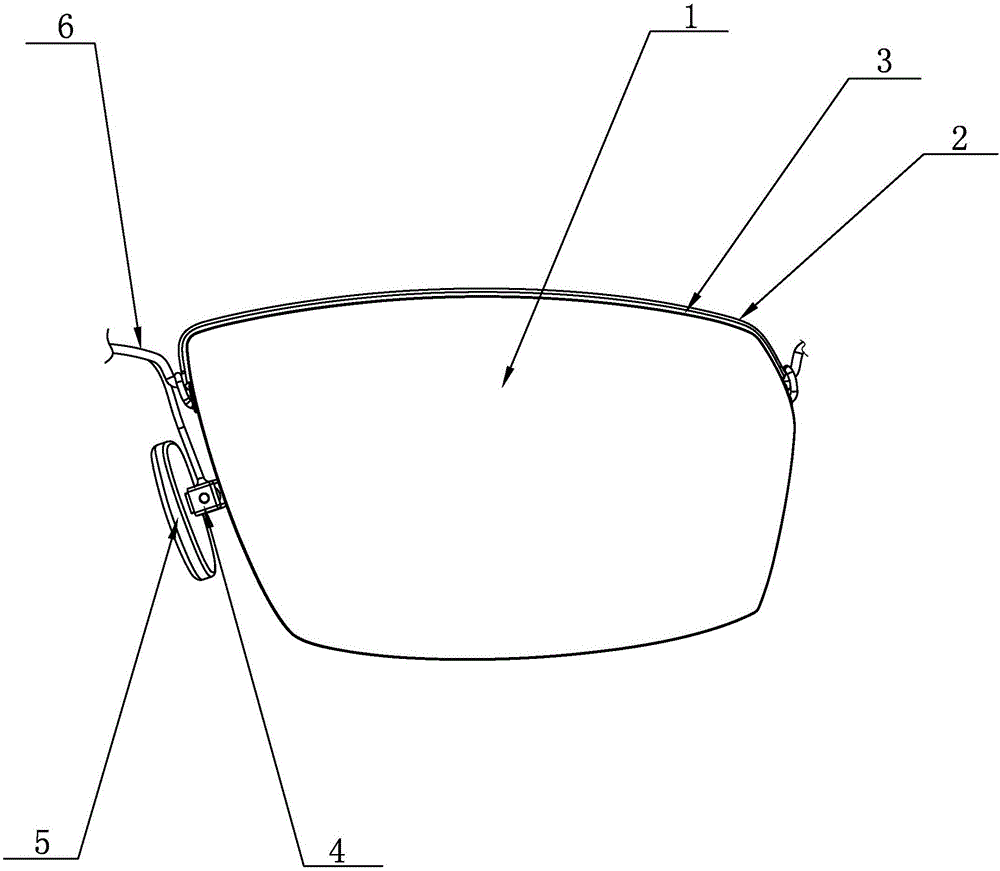

[0019] see figure 1 and figure 2 , a spectacle lens fixing device disclosed in the present invention includes a lens 1 and a wire drawing 2, the lens 1 is provided with a wire drawing groove 11, and a wire drawing bracket 3 is arranged in the wire drawing groove 11, and the wire drawing bracket 3 includes The positioning insertion strip 31 and the arc-shaped supporting piece 32 matched with the wire drawing groove 11, the inner end of the arc-shaped supporting piece 32 is integrally arranged with the outer end of the positioning insertion strip 31, and the middle part of the outer end of the arc-shaped supporting piece 32 is provided with a limiter. Positioning groove 321, the limiting groove 321 is a semicircular groove, the drawing wire 2 is embedded in the limiting groove 321, and the drawing wire bracket 3 is pressed against the lens 1 by tightening the drawing wire 2.

[0020] Preferably, the wire drawing groove 11 is arranged in the middle of the side of the lens 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com