Stranded wire full-automatic tensioning experiment device based on spoked wheel structure

A test device, fully automatic technology, applied in the direction of measuring device, using stable tension/pressure test material strength, sequence/logic controller program control, etc., can solve the problem of inaccurate strand tension test data and other problems , to achieve the effect of realizing automatic control, improving stability and ensuring smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

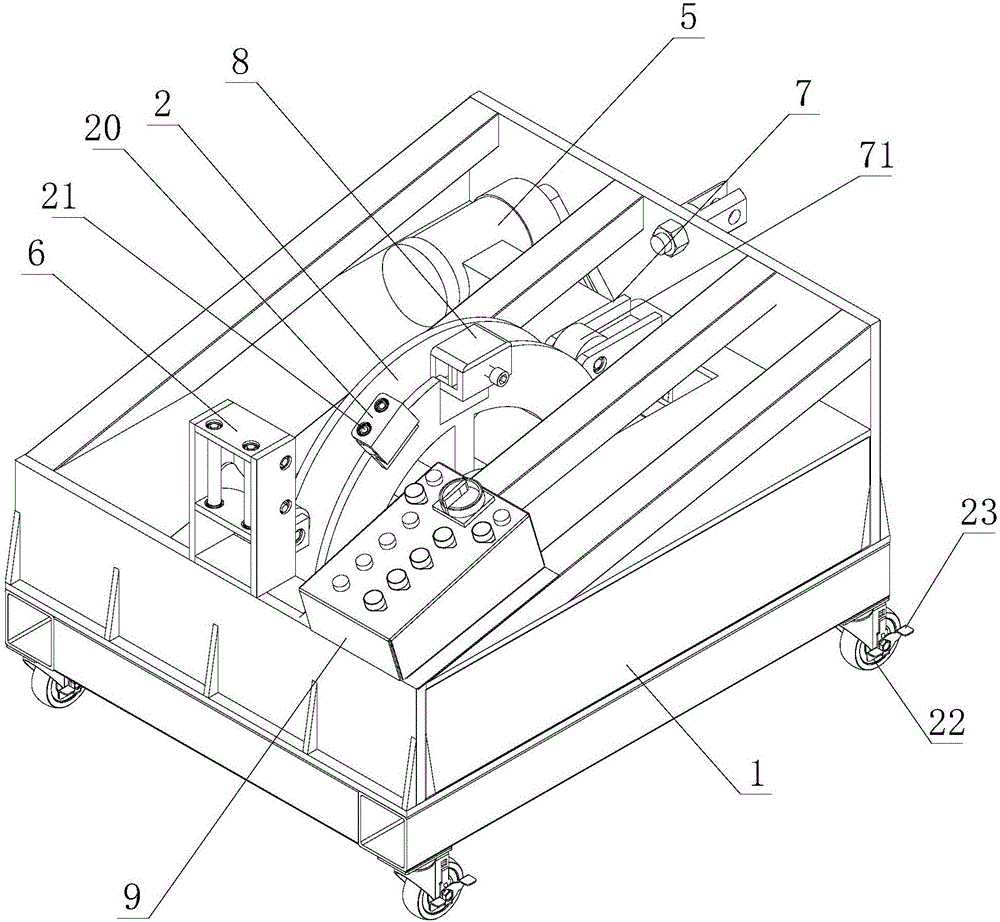

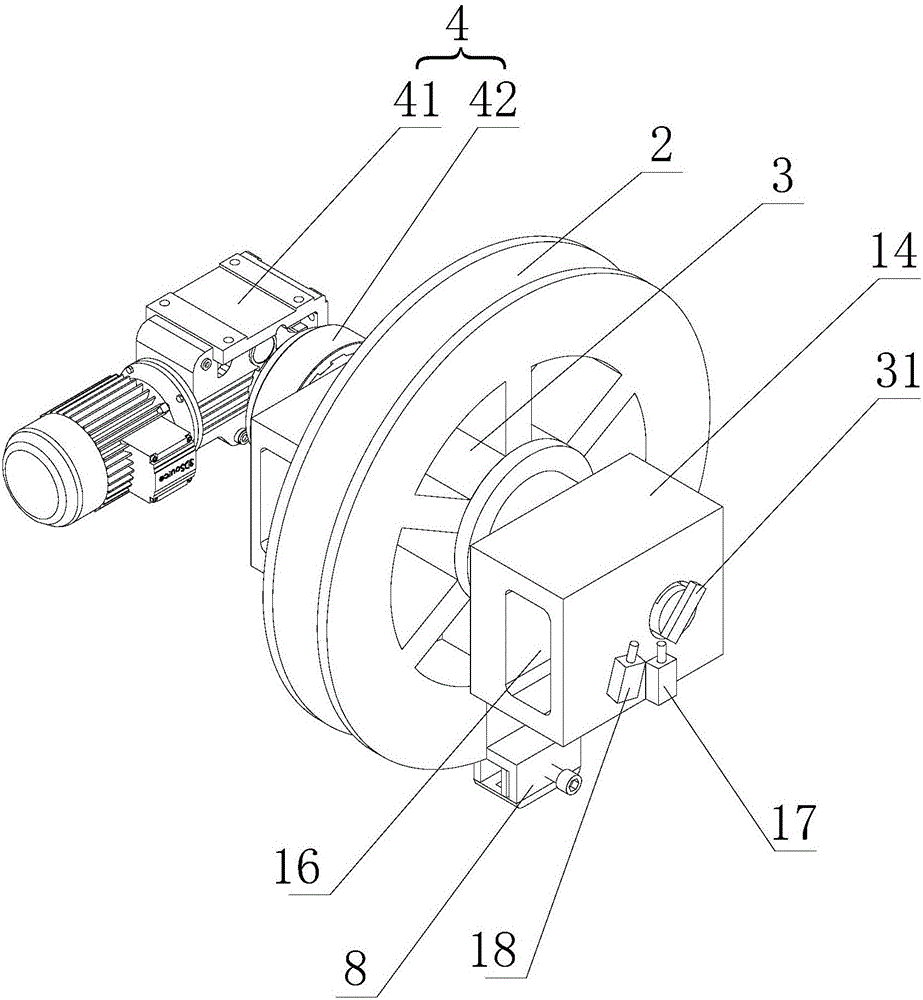

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the fully automatic tensioning test device for stranded wires based on the spoke structure includes a frame 1 and a spoke 2, the spoke 2 is connected to the frame 1 through the first rotating shaft 3 in rotation, and the frame 1 is provided with a drive connected to the first rotating shaft 3 Component 4, the frame 1 is provided with a locking device 5 that locks the first rotating shaft 3, the spoke 2 is provided with a compression component 8 for compressing the stranded wire, and the frame 1 is provided with a guide assembly that facilitates the stranded wire to go out and enter the wire 6.

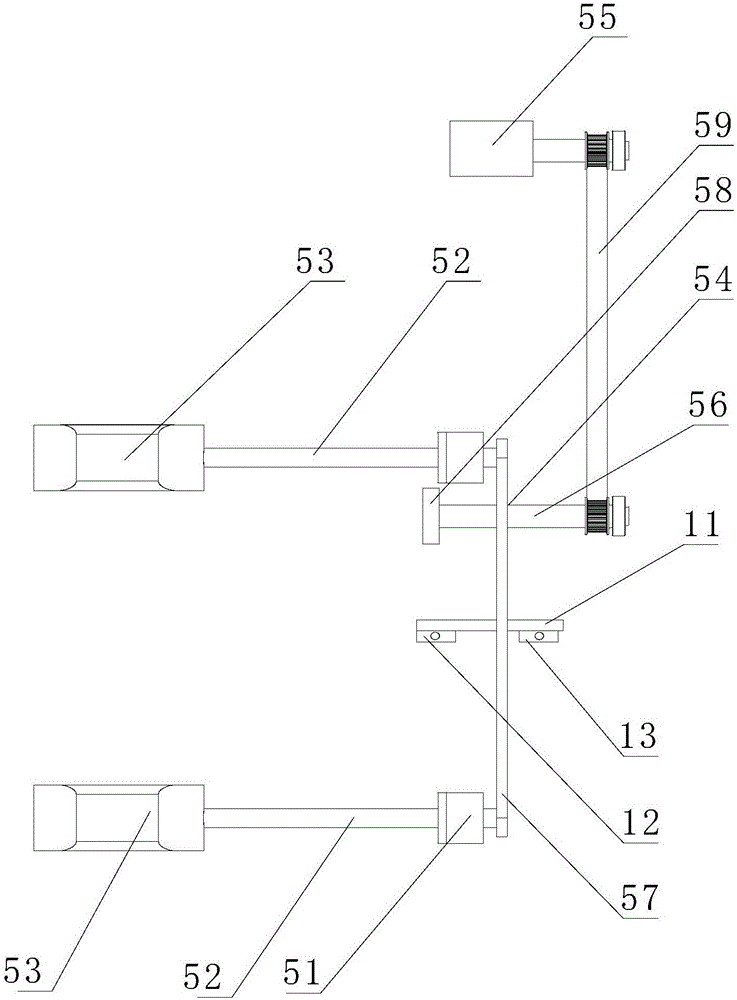

[0024] The locking device 5 includes a first linear bearing seat 51 and a polished rod 52 arranged on the first linear bearing seat 51, the first linear bearing seat 51 is arranged on the frame 1, and one end of the polished rod 52 is provided with a clamping first The brake block 53 of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com