An automatic measurement method for diamond color grading

A technology of color grading and automatic measurement, which is applied in the direction of color measurement devices and color measurement using electric radiation detectors. The effect of linearity error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] The invention is mainly composed of a sample collection system, a microscopic area positioning and display system, and a spectrum collection and calculation system.

[0035] (1) The sample collection system includes:

[0036] Light source conforming to CIE standard illuminant D65, adjustable two-dimensional platform and V-groove.

[0037] Put the tested diamond sample in the V-shaped groove, and the light source illuminates the surface of the V-shaped groove. The surface is a white diffuse surface with an average spectral reflectance of 95% and no spectral selectivity. The V-shaped groove ensures that the tested diamond The sides of the sample are kept perpendicular to the measuring head. At the same time, the V-shaped groove is in an adjustable state, and the purpose of the adjustment is to make each measuring surface of the diamond sample in the groove conveniently rotate for convenient measurement. The light enters the sample under test after being diffused. The c...

Embodiment 2

[0046] Embodiment 2: experimental process

[0047] (1) Uniformity test of samples

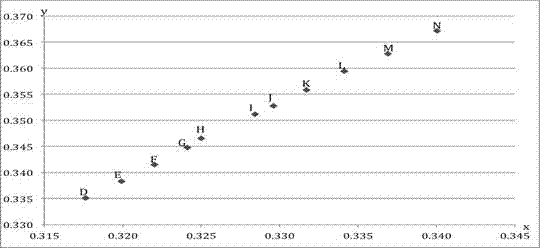

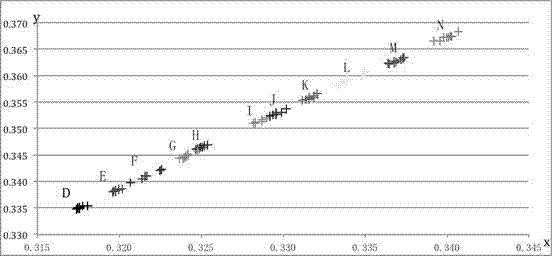

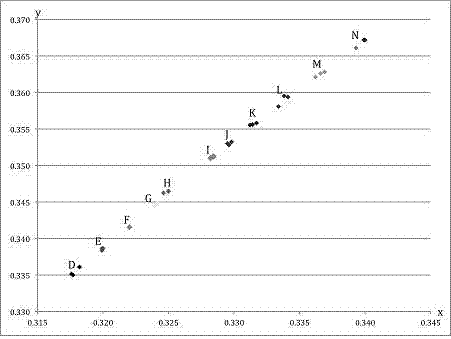

[0048]After many comparisons, the 2013 standard object developed by NGTC was selected, and the measured results were calculated by the color calculation system to obtain the chromaticity coordinates (x, y) of the diamond color, projected on the coordinate axis as figure 1 As shown, it can be seen that all projection points are basically distributed linearly, except for G, H, and I, the overall uniformity is good.

[0049] The differences between x, y, and indices between adjacent color levels are shown in the table below.

[0050]

[0051] (2) Stability and error testing of results

[0052] Taking the D color diamond as an example, fix the same test surface and test it ten times in a row. The results are shown in the table below.

[0053]

[0054] From the data in the table, it can be seen that the stability and reproducibility of the test results are good. Due to the rigor of the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com