A balance sink structure for eliminating the hydraulic power of the cartridge valve core

A technology of hydraulic power and cartridge valve, applied in valve details, valve device, sliding valve, etc., can solve the problems of poppet valve spool prone to vibration, hydraulic system damage, hydraulic system pressure fluctuation, etc., to eliminate the cartridge valve hydrodynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

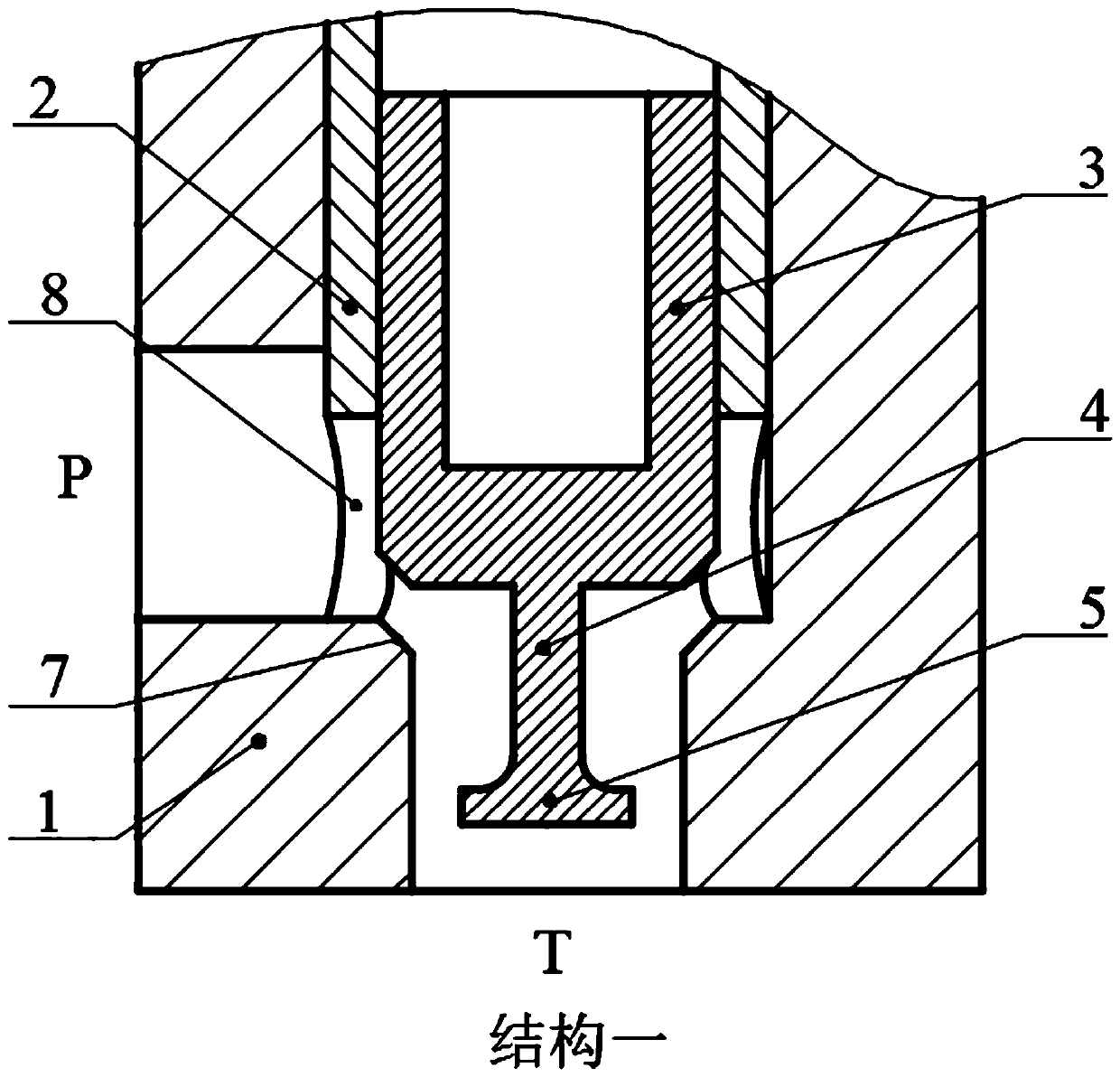

[0025] The first structure is a cartridge valve, such as figure 1 As shown, it includes a valve body 1, a valve sleeve 2, a valve core 3, a connecting rod 4 and a balance pendant 5.

[0026] In structure one, there is a chamfer 7 inside the valve body 1, and the valve body 1 has two oil ports, which are the oil inlet P and the oil return port T; the valve sleeve 2 is installed inside the valve body, and the valve sleeve is evenly distributed in the circumferential direction The four throttle holes 8 and the valve core 3 are installed in the cylindrical hole inside the valve sleeve to form a sliding fit. The balance pendant 5 is connected with the valve core 3 through the connecting rod 4 as a whole.

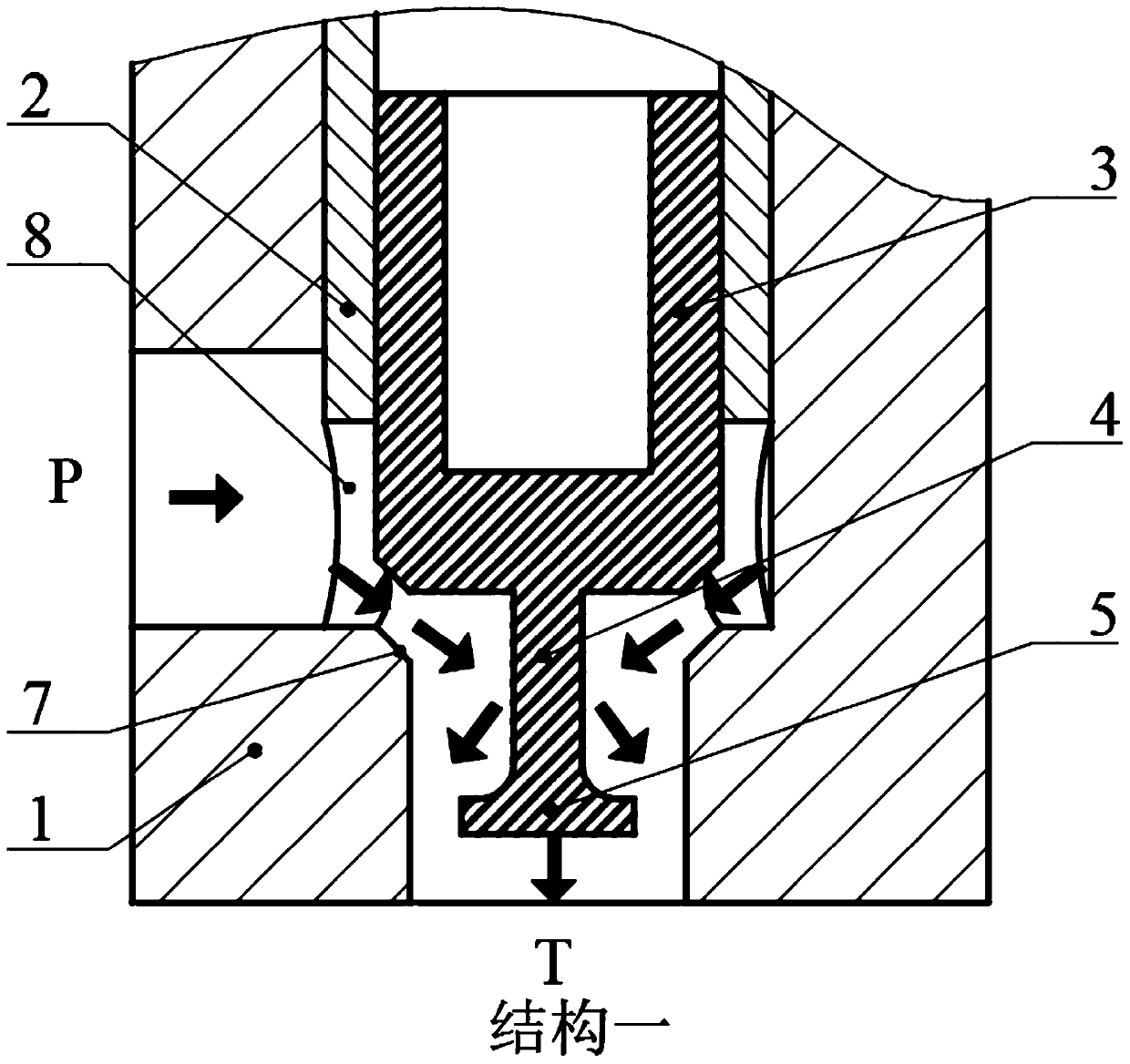

[0027] The present invention eliminates the working principle of cartridge valve spool hydraulic power as follows:

[0028] The working principle of structure one is as follows image 3 As shown, the spool 3 moves upward to open the oil passage groove, so that the hydraulic oil...

Embodiment 2

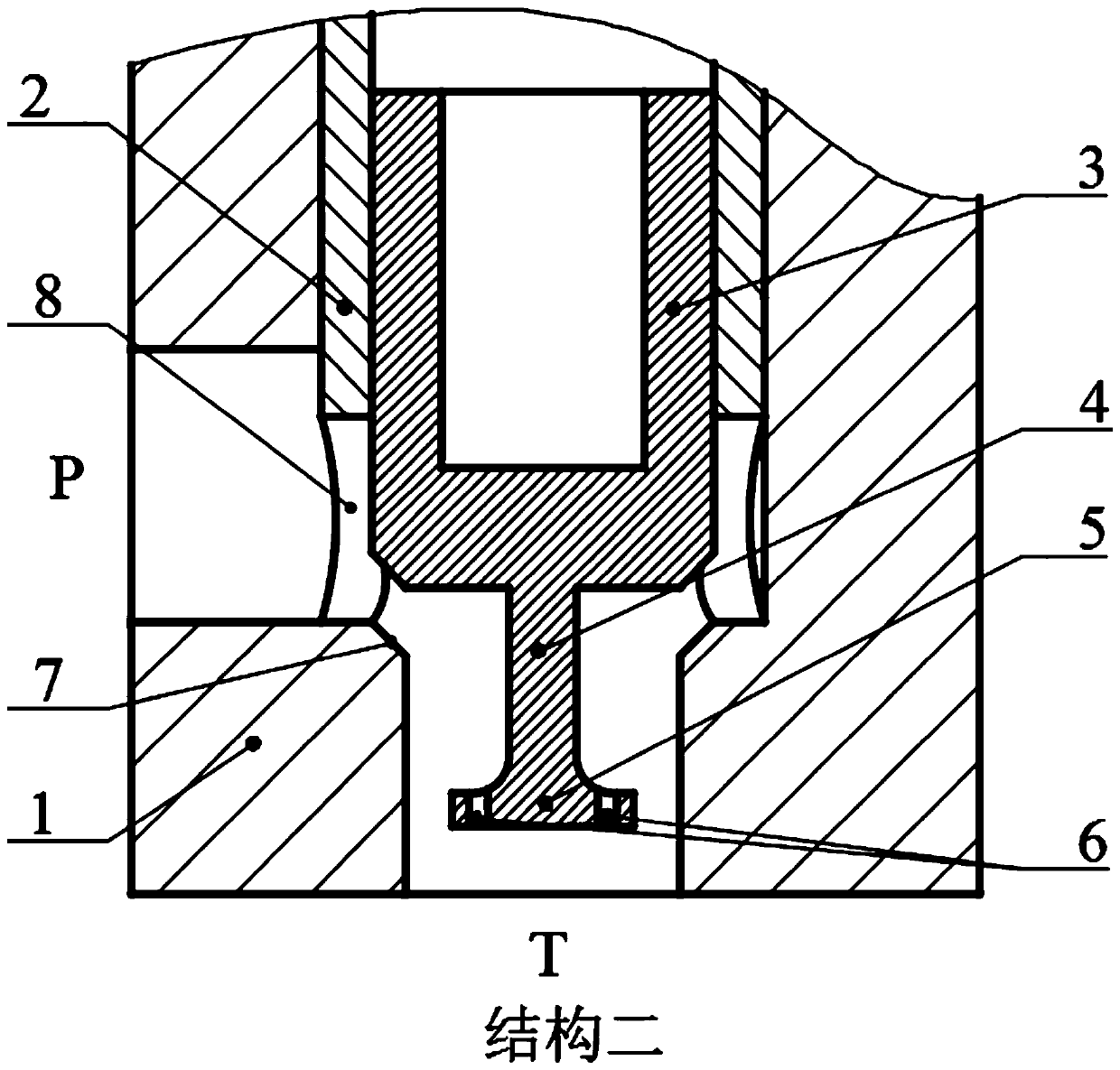

[0034] The second structure is a cartridge valve, such as figure 2 As shown, it includes valve body 1, valve sleeve 2, valve core 3, connecting rod 4, balance pendant 5 and diversion hole 6.

[0035] In structure 2, there is a chamfer 7 inside the valve body 1, and the valve body 1 has two oil ports, which are the oil inlet P and the oil return port T; the valve sleeve 2 is installed inside the valve body, and the valve sleeve is evenly distributed in the circumferential direction Four throttle holes 8, the valve core 3 are installed in the cylindrical hole inside the valve sleeve to form a sliding fit, and the balance pendant 5 is connected with the valve core 3 through the connecting rod 4 as a whole; the diversion hole 6 is located on the balance pendant 5, Evenly distributed in the circumferential direction, forming a balance pendant with holes.

[0036] The working principle of structure two is as follows Figure 4 As shown, the spool 3 moves upward to open the oil pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com