Buffer energy-absorbing structure

A technology of energy-absorbing structures and foam materials, applied to springs made of plastic materials, springs/shock absorbers, mechanical equipment, etc., can solve problems such as low buffer energy absorption efficiency and unreasonable energy-absorbing structures, and achieve energy absorption The effect of strong capacity, good level of load consistency and stable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

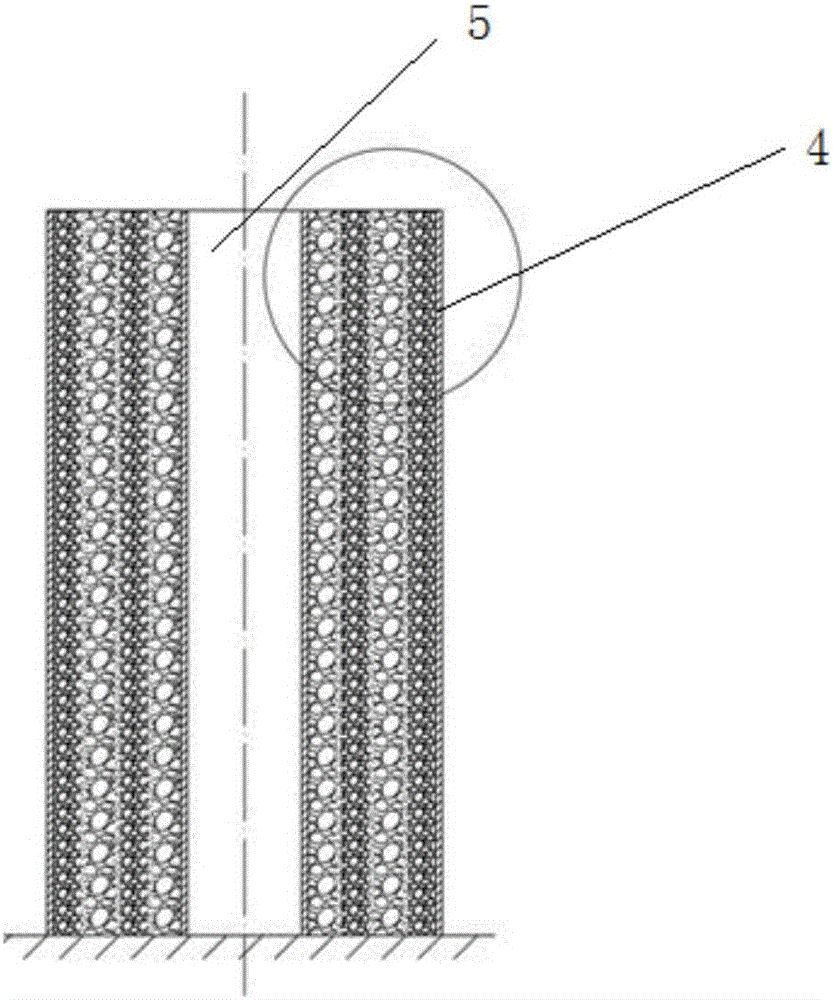

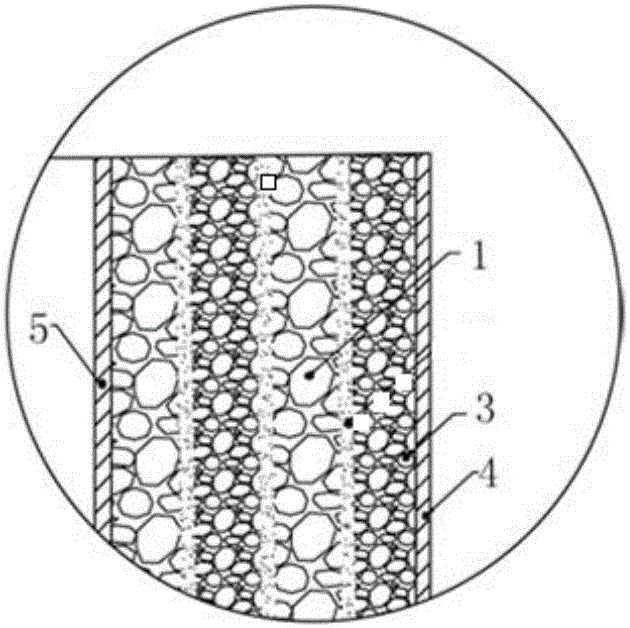

[0026] An embodiment of the buffer energy-absorbing structure of the present invention, the structure schematic diagram of the buffer energy-absorbing structure described in this embodiment is as attached figure 1 And attached figure 2 shown, including

[0027] The outer tube 4 and the inner tube 5 arranged in the outer tube 4, four foam layers are arranged between the inner wall of the outer tube 4 and the outer wall of the inner tube 5, and the foam layers are all filled with positive Poisson's ratio foam materials or negative Poisson's ratio foam materials. Compared with the foam material, two adjacent foam layers are connected by welding, and the foam materials in the adjacent foam layers are alternately arranged in positive and negative Poisson's ratio in the radial direction, and the foam layer at the outer wall end of the inner tube 5 is filled with Negative Poisson's ratio foam material 3, the foam layer at the inner wall end of the outer tube 4 is filled with a posi...

Embodiment 2

[0029] An embodiment of the buffer energy-absorbing structure of the present invention, the structure schematic diagram of the buffer energy-absorbing structure described in this embodiment is as attached figure 1 And attached figure 2 shown, including

[0030] The outer tube 4 and the inner tube 5 arranged in the outer tube 4, six foam layers are arranged between the inner wall of the outer tube 4 and the outer wall of the inner tube 5, and the foam layers are all filled with positive Poisson's ratio foam materials or negative Poisson's ratio foam materials. Compared with the foam material, two adjacent foam layers are connected by bonding, and the foam materials in the adjacent foam layers are alternately arranged in positive and negative Poisson's ratio in the radial direction, and the foam layer at the outer wall end of the inner tube 5 is filled There is a negative Poisson's ratio foam material 3, and the foam layer at the inner wall end of the outer tube 4 is filled wi...

Embodiment 3

[0032] An embodiment of the buffer energy-absorbing structure of the present invention, the structure schematic diagram of the buffer energy-absorbing structure described in this embodiment is as attached figure 1 And attached figure 2 shown, including

[0033] The outer tube 4 and the inner tube 5 arranged in the outer tube 4, two foam layers are arranged between the inner wall of the outer tube 4 and the outer wall of the inner tube 5, and the two foam layers are connected by one-time molding by 3D printing, and the inner tube The foam layer at the outer wall end of the outer tube 5 is filled with a negative Poisson's ratio foam material 3, and the foam layer at the inner wall end of the outer tube 4 is filled with a positive Poisson's ratio foam material 1, and the absolute value of the Poisson's ratio of the foam material in the two layers of foam layers is the same. The thickness, porosity, and relative density of the material are the same, the positive Poisson's ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com