Through type hydraulic swing oil cylinder

A hydraulic swing and through-type technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems of difficult installation of stator blades and rotor blades, difficulties in blade sealing and end face sealing, and driving driven equipment can only be driven on one side. The amplitude and direction are clear, the installation efficiency is improved, and the installation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

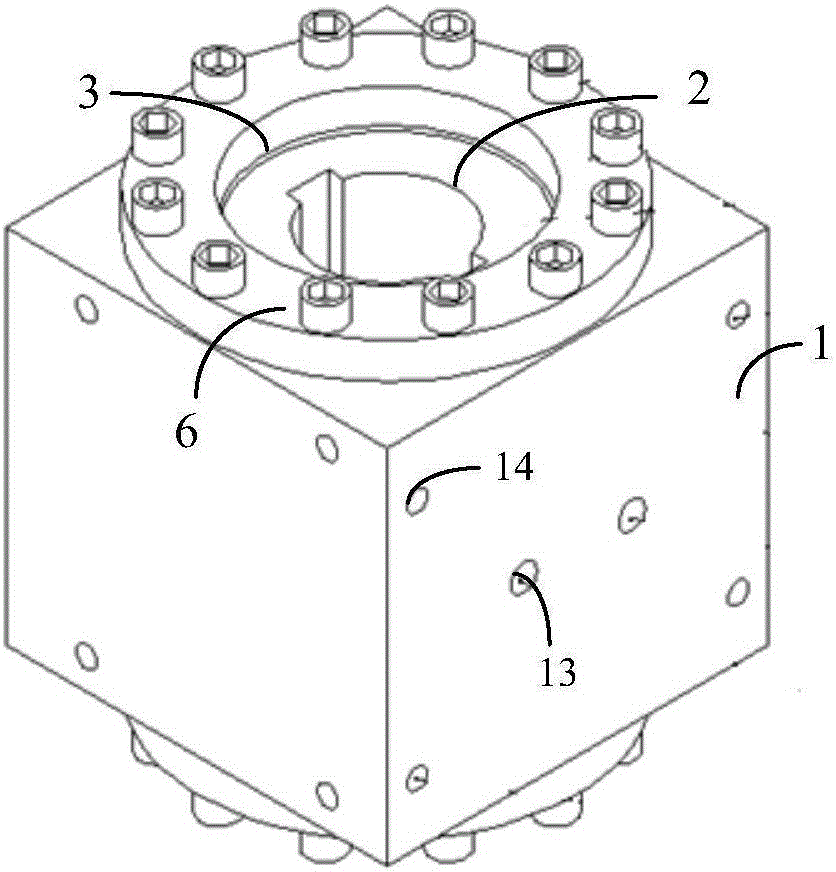

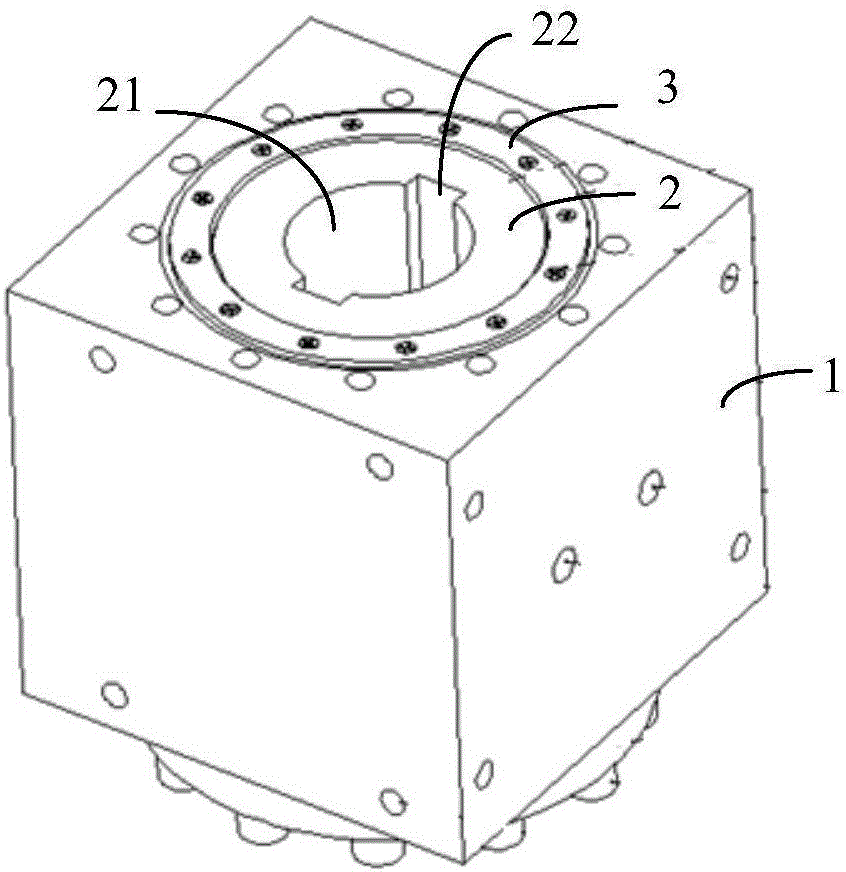

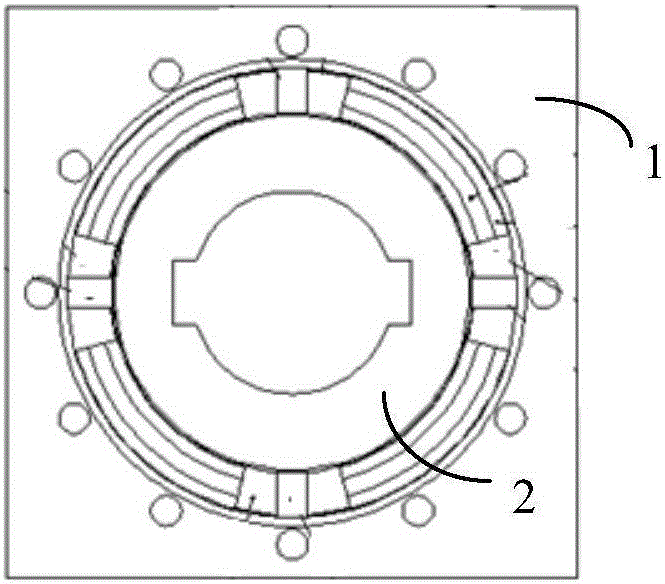

[0028] figure 1 It is a schematic structural diagram of a through-type hydraulic swing cylinder in a preferred embodiment of the present application; figure 2 for this application figure 1 A partial schematic diagram of the through-type hydraulic swing cylinder; image 3 for this application figure 1 Another partial schematic diagram of the through-type hydraulic swing cylinder; please also refer to Figure 1 to Figure 3 , The present application provides a through-type hydraulic oscillating cylinder, the through-type hydraulic oscillating cylinder includes: a cylinder stator 1 , a cylinder rotor 2 , an end face seal 3 , a rotor blade 4 and a stator blade 5 .

[0029] see Figure 6 , the cylinder stator 1 is a hollow structure, the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com