Magnetic attraction type plate structure

A magnetic suction type and plate technology, which is applied in the direction of building structure, coating, construction, etc., can solve the problems of inability to achieve convenient operation, narrow splicing gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

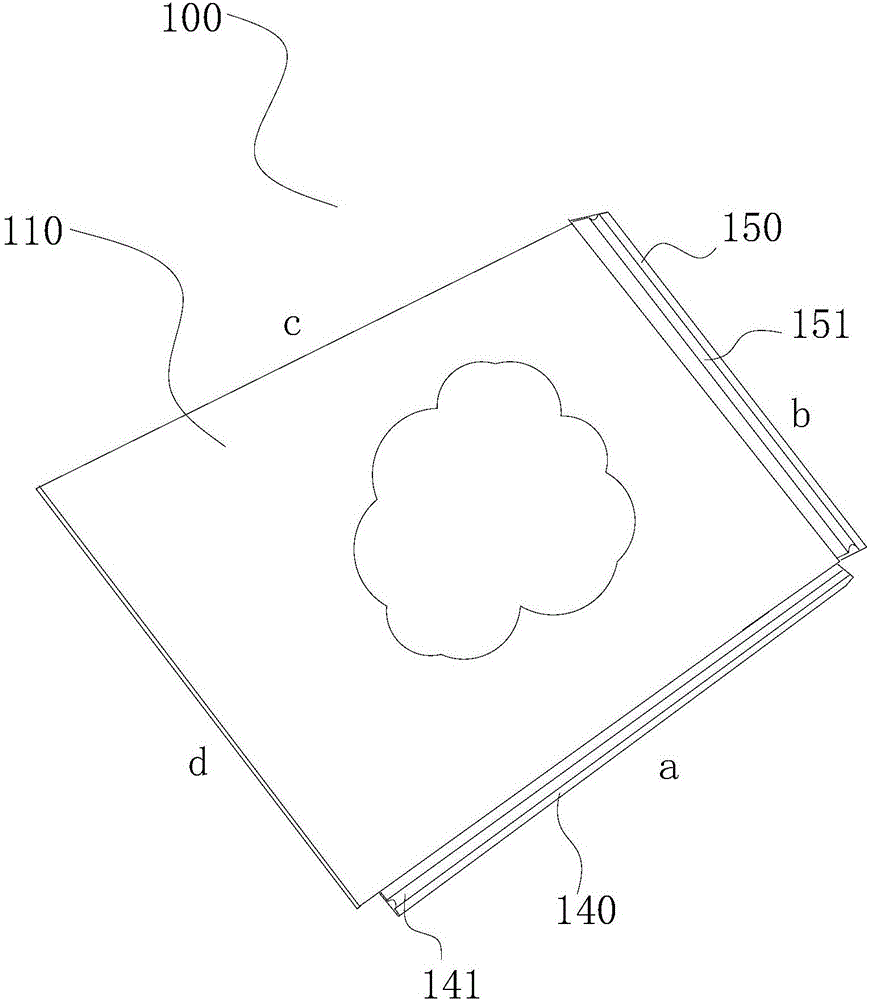

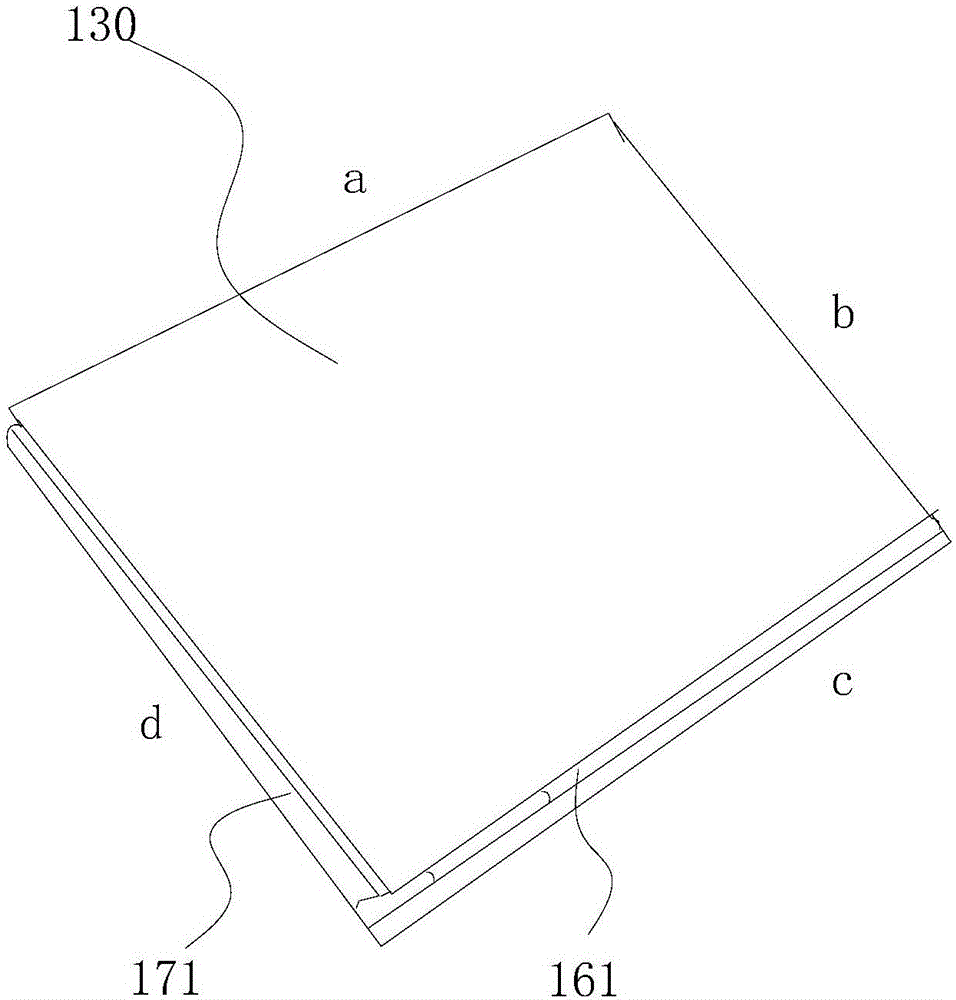

[0051] A magnetic plate structure, comprising: a magnetic coating arranged on a decorative surface to be installed and a plate 100 for magnetically attracting the magnetic coating, such as figure 1 , figure 2 shown.

[0052] Among them, the magnetic coating is applied to the decorative surface to be installed. The decorative surface to be installed can be the ground, or a wall or other building surfaces. By disposing a magnetic coating on the decorative surface to be installed, the plate 100 is fixedly installed on the decorative surface through the magnetic coating.

[0053] Specifically, the plate 100 is provided with a magnetic glue layer 110, a plastic shaped layer and a surface texture layer 130, the magnetic glue layer 110, the plastic shaped layer and the surface texture layer are sequentially stacked and fixedly connected, and the magnetic glue layer 110 is attracted to the magnetic coating. The magnetic adhesive layer 110 may be an adhesive layer containing iron p...

Embodiment 2

[0066] A magnetic plate structure, other features are the same as those of Embodiment 1, and also has the following technical features.

[0067] The preparation process of the magnetic coating includes the steps of pretreatment and coating treatment on the decorative surface;

[0068] The pretreatment is to coat the decorative film with an interface agent to form an interface agent layer, and seal the pores on the decoration surface through the interface agent layer, wherein the interface agent is a nanoscale water-based acrylic emulsion;

[0069] The coating treatment is to coat the magnetic coating on the surface of the interface layer to form the magnetic coating.

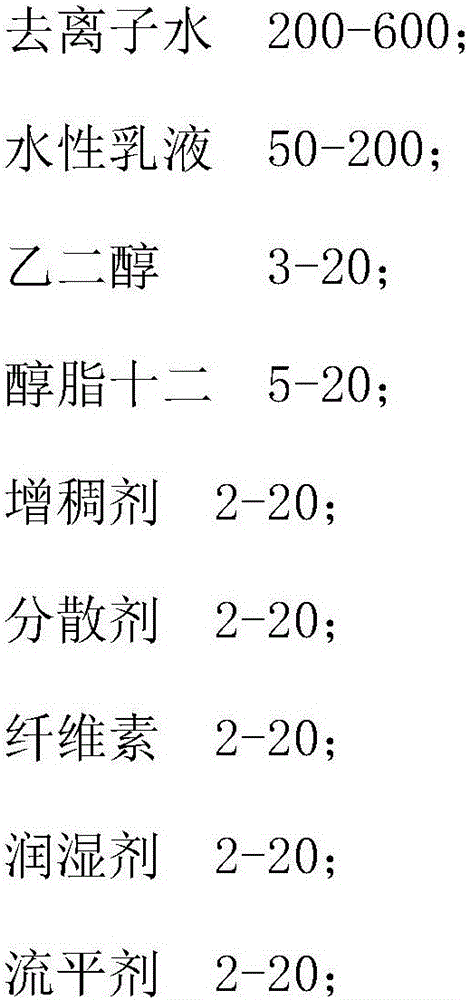

[0070] Specifically, the magnetic plate structure, in parts by weight, each part of the magnetic coating includes:

[0071]

[0072]

[0073] Among them, the water-based emulsion is acrylic acid, the preservative is a polyisothiazolone water-based mixture, the thickener is a water-based thickener, the cel...

Embodiment 3

[0077] A magnetic plate structure, the other features are the same as in Example 2, and also has the following technical features: the water-based emulsion is polyurethane. The basaltic magnetic coating of this formula has the characteristics of strong adsorption and good conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com