Adjustable material door mechanism of spreading machine

A paver and adjustable technology, applied in roads, road repair, roads, etc., can solve the problems of high cost, inconvenient on-site intuitive control of paving personnel, etc., to prevent excessive lifting, simple structure, accurate and reliable control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

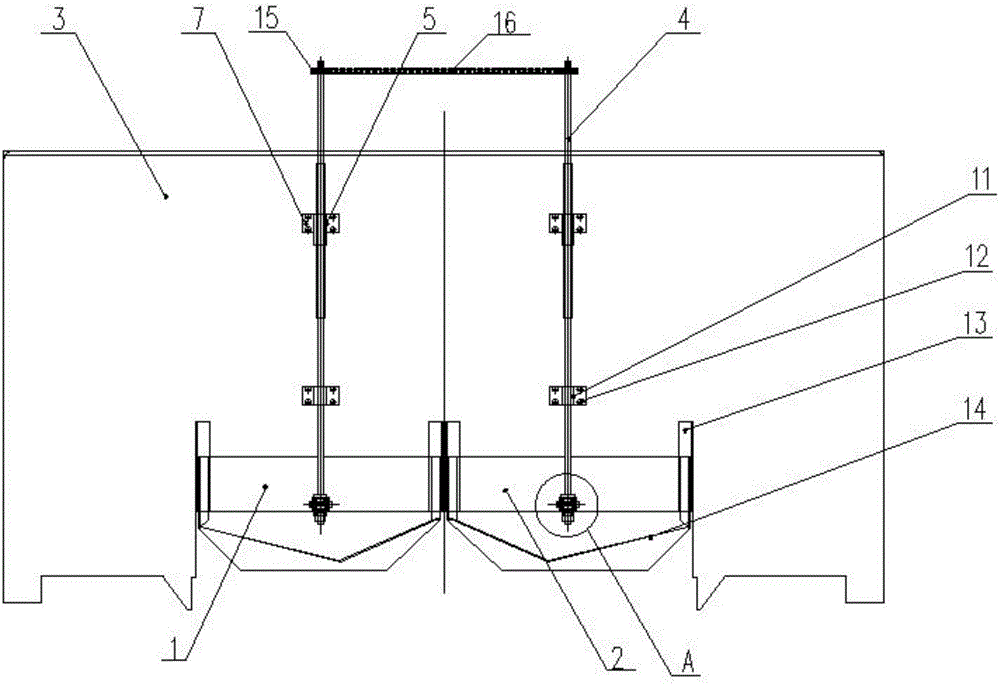

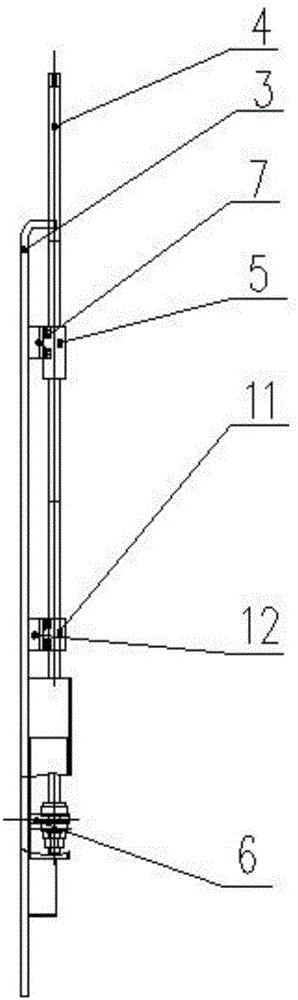

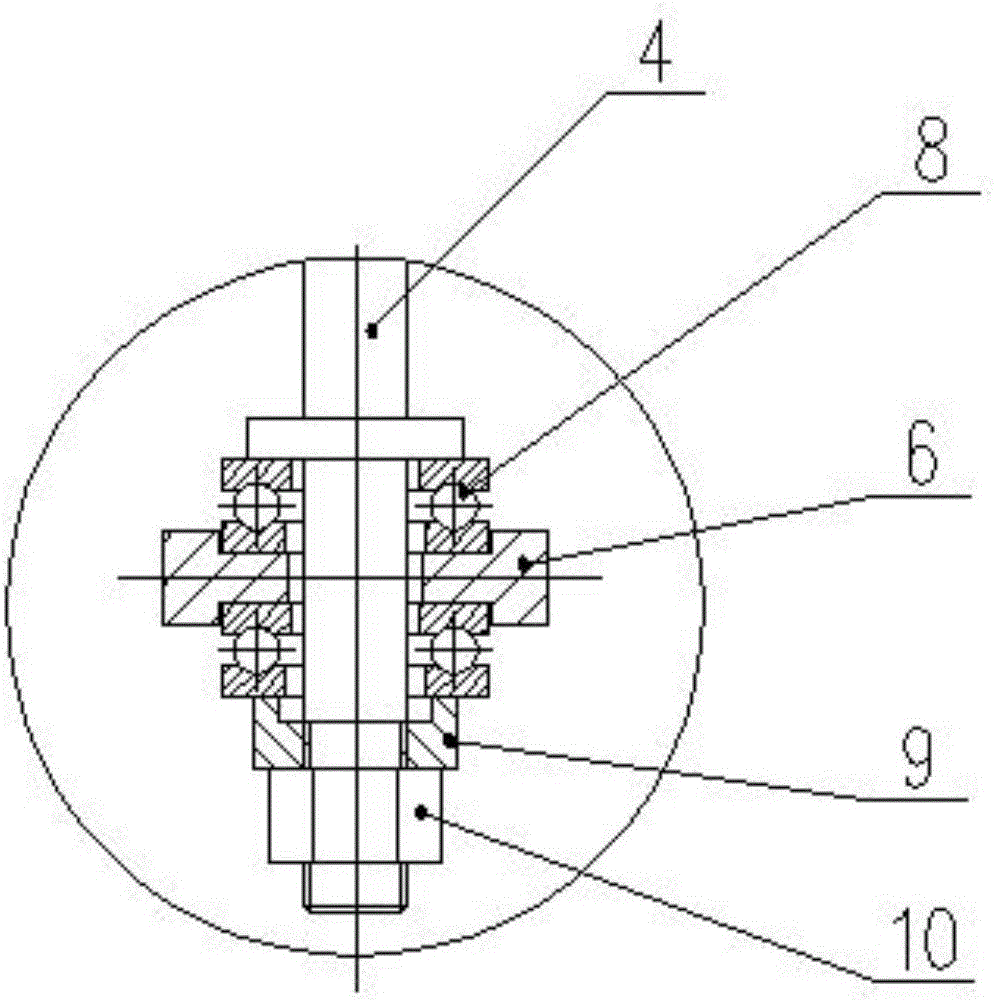

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] Such as Figure 1 to Figure 5 As shown, an adjustable paver material door mechanism includes a left material retaining plate 1, a right material retaining plate 2 and a frame front end plate 3, and the left material retaining plate 1 and the right material retaining plate 2 are respectively installed on the front end plate 3 The left feed port and the right feed port also include a long screw 4, a threaded sleeve 5 and a bearing seat 6, the threaded sleeve 5 is fixed on the front end plate 3 through the backing plate I7, and the bearing seat 6 is fixed on the left In the middle of the baffle plate 1 and the right baffle plate 2, the threaded section at the upper end of the long screw rod 4 cooperates with the threaded sleeve 5, and the optical axis section at the lower end of the long screw rod 4 passes through the bearing seat 6 and is installed through the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com