Special film for ginger planting

A film and mucous membrane technology, applied in the field of special film for ginger planting, can solve the problems that the increase or decrease of the addition amount cannot satisfy the transmitted light quality of ginger, cannot maintain the light environment for ginger growth, and the film strength decreases, etc., so as to improve the quality of ginger. , the effect of reducing the cellulose content of ginger and increasing the photosynthetic rate of leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

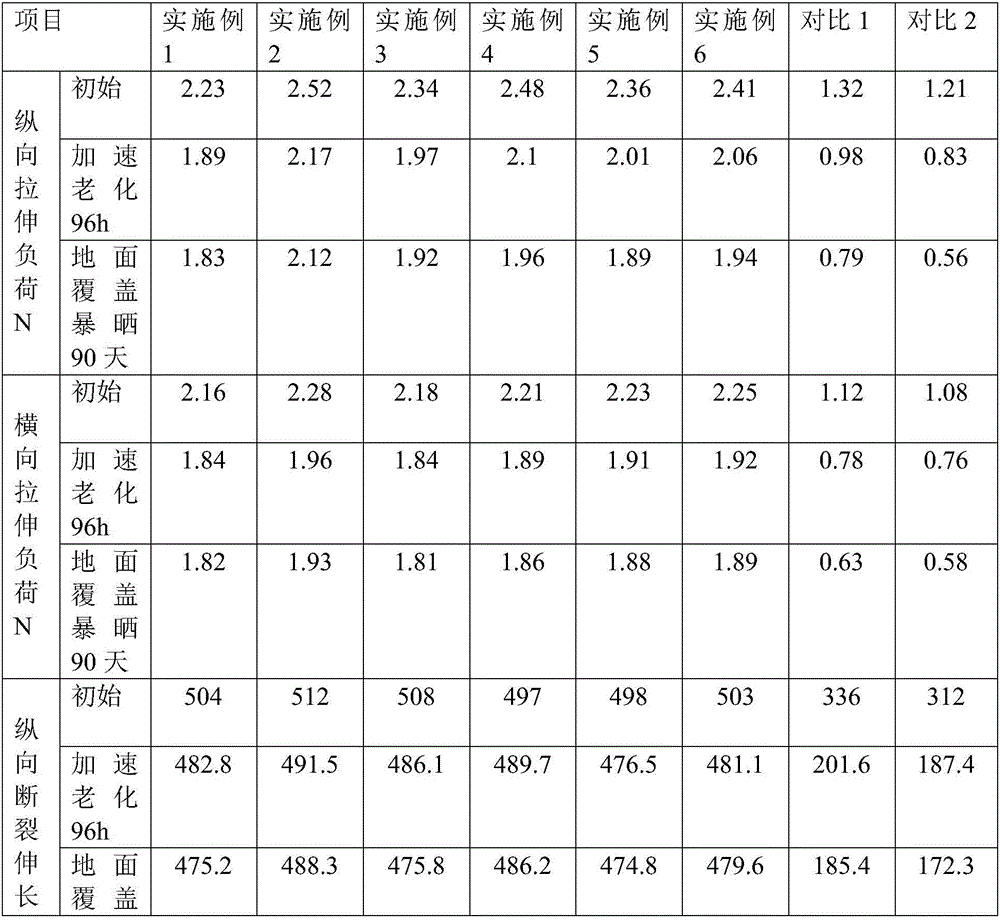

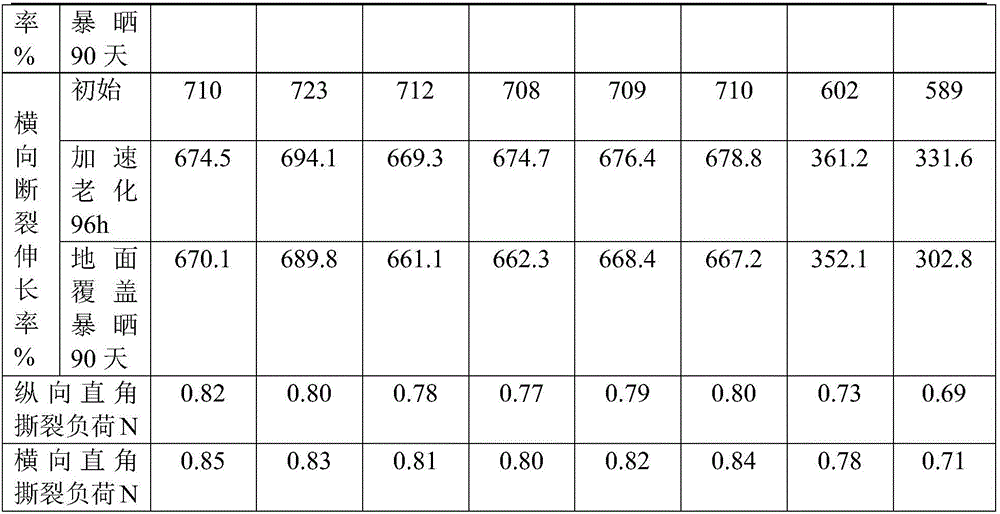

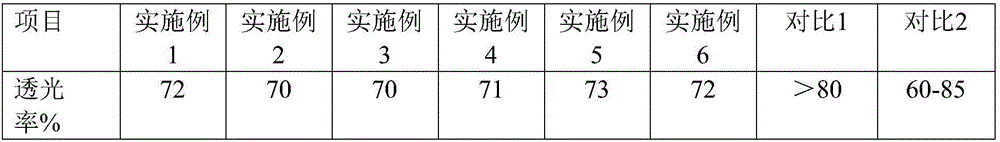

Examples

Embodiment 1

[0026] A special film for ginger planting, by mass percentage, including white high-pressure recycled plastic particles 15%, white EVA mucous membrane recycled plastic particles 32%, blue high-pressure recycled plastic particles 42%, blue anti-fog, anti-aging double anti-mother 10% of raw materials, 1% of dark blue masterbatch.

Embodiment 2

[0028] A special film for ginger planting, by mass percentage, including white high-pressure recycled plastic granules 18%, white EVA mucous membrane recycled plastic granules 30%, blue high-pressure recycled plastic granules 40%, blue anti-fog, anti-aging double anti-mother 10% of raw materials, 2% of dark blue masterbatch.

Embodiment 3

[0030] A special film for ginger planting, by mass percentage, including white high-pressure recycled plastic granules 16%, white EVA mucous membrane recycled plastic granules 31%, blue high-pressure recycled plastic granules 39%, blue anti-fog, anti-aging double anti-mother 11% of raw materials, 3% of dark blue masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com