Method for electric dehydration of sludge strengthened by conditioning salt

An electric dehydration and sludge technology, which is applied in the direction of electrochemical sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of high energy consumption, reduce dehydration energy consumption, reduce energy consumption, The effect of enhancing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

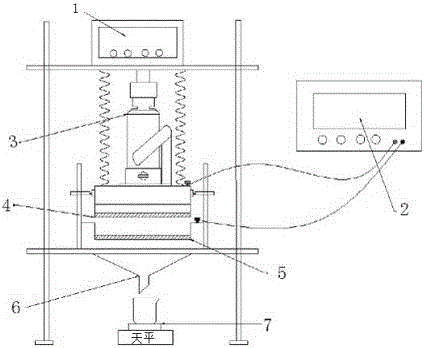

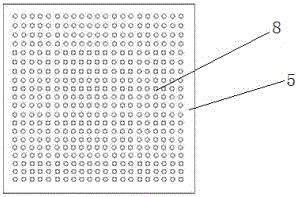

[0028] as attached figure 1 As shown, this embodiment provides a sludge dewatering equipment with vertical pressurization combined with electro-osmosis technology, including a pressure applicator 3, an anode plate 4, a cathode plate 5, a drainage device 6 and a water storage device 7 arranged from top to bottom , also includes an external power supply 2; the anode plate and the cathode plate are respectively connected to the external power supply 2 (the connection method refers to the existing power supply anode and cathode connection mode); the anode plate 4 and the cathode plate 5 are arranged horizontally, and the anode plate 4 Placed on the cathode plate 5, the space between the anode plate 4 and the cathode plate 5 is used as a place for filling sludge, and the cathode plate 5 is provided with a number of holes 8 for the water in the sludge to flow out. The number and diameter of the holes 8 are not strictly limited, as long as they are suitable for water to flow out.

Embodiment 2

[0030] Take 120.00g of sludge, mix it fully with 5mL of deionized water, and fill it into the sludge filling tank with a thickness of 0.5cm. Place a 300-mesh nylon mesh filter cloth between the sludge and the cathode plate, adjust the pressure to 15kPa, and the voltage Combined electric dehydration test after 8V. It takes 56.50±0.71min for electroosmosis to reduce the moisture content of sludge to 60%, and the dehydration energy consumption is 0.054±0.012kWh / kg sludge.

[0031] This embodiment can use the device described in Embodiment 1.

Embodiment 3

[0033] The schematic diagram of the process method of this embodiment is shown in the attached image 3 shown. Take 120.00g of sludge, weigh Na at the ratio of 1.0g / kg of sludge 2 HPO 4 , Dissolve it in 5mL deionized water and mix it fully with the sludge, fill it into the sludge filling tank, the filling thickness is 0.5cm, place a 300-mesh nylon mesh filter cloth between the sludge and the cathode plate, adjust the pressure to 15kPa, and the voltage to After 8V, the combined electric dehydration test was carried out. It takes 25.00±1.41min for electroosmosis to reduce the moisture content of sludge to 60%, and the dehydration energy consumption is 0.033±0.001kWh / kg sludge.

[0034] This embodiment can use the device described in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com